Member III

maybe when the warranty is up I'll go a step further but on the Subaru the strut are the biggest limiter on tire size

Member III

True... unless you go with more backspace or spacers but I know you don’t like the tire poke. Flings a lot of unneeded mud and gritmaybe when the warranty is up I'll go a step further but on the Subaru the strut are the biggest limiter on tire size

True... unless you go with more backspace or spacers but I know you don’t like the tire poke. Flings a lot of unneeded mud and gritmaybe when the warranty is up I'll go a step further but on the Subaru the strut are the biggest limiter on tire size

Member III

Member III

Member III

Looking good mate!

Member III

Member III

Member III

Member III

Haha dig it man

Member III

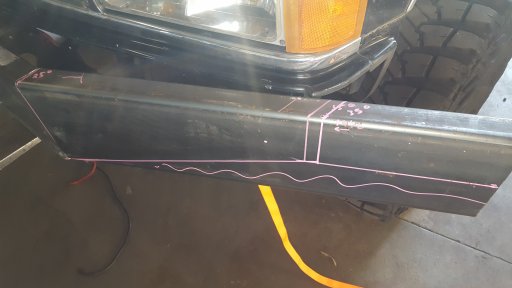

Yeah man I agree. I made my outlander front and rear bumpers for like 250$ haha.my thoughts are something simple like the one I made for my grand Cherokee, just have to build the filler pieces a little different or get another stock bumper to chop up for the filler , it's got some odd angles that will take some work to make the steel bumper work right . View attachment 76185

Member III

Member III

Member III