So it's been a while, and that's mainly due to all the things that have been going wrong...

BUT I do have progress to show! First off shock towers:

The new shock towers have been fabricated, welded in and painted with all new Fox shocks installed. The new eyelet at the top is roughly 5" higher, and I don't think I'll have to cut into the body. I've also deleted the track bar and relocated (so they're actually functional) the bump stops. I ended up with about 4" of extra up travel and only 1~1.5 in down travel, which is still way way more than the 4x4 kit originally had

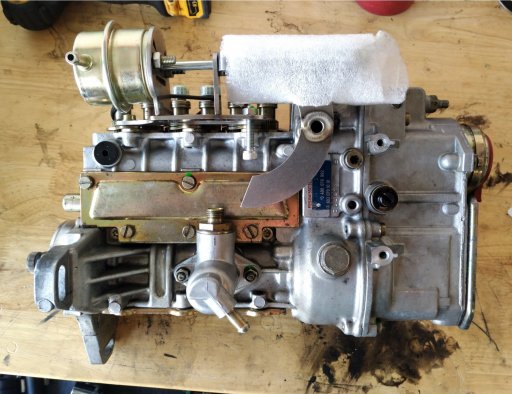

Now for the engine! (don't mind the broomstick, I was using it to take measurements)

I could get it to work as it's placed but I think I'm going to pull the whole drivetrain out again so I can notch the crossmember. That will allow me to drop it another 1.5" giving me just that little bit more wiggle room under the dog house (ease of maintenance down the road and better transmission angle)

Now, for all the headaches I've had since finally getting the right engine!

1) Engine hoist not long enough so I had to mod the boom, but that was kinda fun and I set it up to add a forklift attachment in future.

2) The transmission adapter didn't fit, Speed Gems asks what engine/trans combo you're planning on so they can ensure fit, that apparently didn't happen. The om648 oil pan I'm using has bolt holes in slightly different locations, but the drill press made quick work of that.

3) The clutch that Speed Gems sent with their kit didn't work with my transmission nor their custom machined flywheel... go figure. I ordered a new clutch to just get it together and that at least matched the bolt holes on their custom flywheel but...

4) I have NO idea what pilot bearing I'm supposed to use. It doesn't work with the bearing they provided with the kit (which is a proper Ford pilot bearing) nor the one that came with my new proper clutch. The hole on the flywheel is just too small (1.065" vs 1.375" od pilot bearings for Fords)

I contacted them just a bit too late for their business hours so I'm hoping to hear from them tomorrow. Still, for $1750 I hoped their kit would at least work with the parts they provided. I can kind of understand if their kit doesn't work with the om648 oil sump when it's not necessarily advertised for it but it is billeted for any 1987+ straight 5 & 6 merc engines, which includes the om648. Overall, I'm kinda annoyed at the lack of attention to detail for such a high priced item. Worse comes to worse I can either take the flywheel to a local machine shop to have it lathed to match the Ford pilot bearing, or I think I could get a specific AMC pilot bearing to work from 70s~80s Jeeps

That said the engine and transmission are bolted together for now (sans clutch) for placement and engine mount fabrication. I'd like to get that all designed over this long weekend and maybe welded in next week, I'm taking a bit of time off work so hopefully that'll actually happen. Right now it's looking like I'll have all the room I need under the hood to get what I want in there, it'll be a tight squeeze length wise but I can make it all work with electric fans if need be. Hopefully more updates soon!!!

BUT I do have progress to show! First off shock towers:

The new shock towers have been fabricated, welded in and painted with all new Fox shocks installed. The new eyelet at the top is roughly 5" higher, and I don't think I'll have to cut into the body. I've also deleted the track bar and relocated (so they're actually functional) the bump stops. I ended up with about 4" of extra up travel and only 1~1.5 in down travel, which is still way way more than the 4x4 kit originally had

Now for the engine! (don't mind the broomstick, I was using it to take measurements)

I could get it to work as it's placed but I think I'm going to pull the whole drivetrain out again so I can notch the crossmember. That will allow me to drop it another 1.5" giving me just that little bit more wiggle room under the dog house (ease of maintenance down the road and better transmission angle)

Now, for all the headaches I've had since finally getting the right engine!

1) Engine hoist not long enough so I had to mod the boom, but that was kinda fun and I set it up to add a forklift attachment in future.

2) The transmission adapter didn't fit, Speed Gems asks what engine/trans combo you're planning on so they can ensure fit, that apparently didn't happen. The om648 oil pan I'm using has bolt holes in slightly different locations, but the drill press made quick work of that.

3) The clutch that Speed Gems sent with their kit didn't work with my transmission nor their custom machined flywheel... go figure. I ordered a new clutch to just get it together and that at least matched the bolt holes on their custom flywheel but...

4) I have NO idea what pilot bearing I'm supposed to use. It doesn't work with the bearing they provided with the kit (which is a proper Ford pilot bearing) nor the one that came with my new proper clutch. The hole on the flywheel is just too small (1.065" vs 1.375" od pilot bearings for Fords)

I contacted them just a bit too late for their business hours so I'm hoping to hear from them tomorrow. Still, for $1750 I hoped their kit would at least work with the parts they provided. I can kind of understand if their kit doesn't work with the om648 oil sump when it's not necessarily advertised for it but it is billeted for any 1987+ straight 5 & 6 merc engines, which includes the om648. Overall, I'm kinda annoyed at the lack of attention to detail for such a high priced item. Worse comes to worse I can either take the flywheel to a local machine shop to have it lathed to match the Ford pilot bearing, or I think I could get a specific AMC pilot bearing to work from 70s~80s Jeeps

That said the engine and transmission are bolted together for now (sans clutch) for placement and engine mount fabrication. I'd like to get that all designed over this long weekend and maybe welded in next week, I'm taking a bit of time off work so hopefully that'll actually happen. Right now it's looking like I'll have all the room I need under the hood to get what I want in there, it'll be a tight squeeze length wise but I can make it all work with electric fans if need be. Hopefully more updates soon!!!

Last edited: