Off-Road Ranger I

Might end up with more wires for the new gauges than the rest of the truck's wires!You have to like the one wire hook up of a diesel, well maybe two to the starter and one to the fuel shut off solenoid.

Off-Road Ranger I

Off-Road Ranger I

Still tight as a drum! My biggest fear was that the heims, being so precise & unforgiving, would translate a ton of vibration into the wheel/cabin. I was happy to find it didn't & actually made the steering feel go from mushy & unresponsive to flat out awesome! I do wonder though, now that the steering is SO strong, if I were to clobber either link into a rock/stump... what would fail 1st? ...the heims or the knuckle it's mounted to?Have you had any issues with the heim joints wearing, with out there being grease and all?

I put just over a year & a half of use on them before the engine crapped out. While it was my daily driver, I was far from easy on them. Didn't bash 'em up rock crawling or anything extreme, but I went on a load of road trips & was offroad every other weekend all through summer & into the salty winters.

I try to regularly maintain all the suspension joints by power washing them clean & hosing them down with white lithium grease spray. I should say though, those joints I used are only really a mid-level quality. The body & ball material is top notch, but the high-end heims are rebuildable & use even better teflon internal bearing surface vs. the nylon in mine. Thankfully, by design, upgrading them is a simple as threading in new ones.

Off-Road Ranger I

Thanks! That's a small "water brick" that I drilled a hole into to fit a little pex valve. Works great for hands-free water, no need for a pump, gravity does the trick. I just refill off my water jerry cans every now 'n then.Awesome build and thanks for taking the time to share. In several pages back you had a pick of a square water holder with what I assume to be modifications for spicket and vent. What was that?

Sent from my iPad using Tapatalk

This is an awesome build thread! Keep us updated! I've always loved Disco's and I would kill to have the money/time to do my own diesel swap in a disco 2. Best part is these trucks won't rust out on you, but you will be fighting electronics for years to come... trade offs I suppose. Are you worried about any of the electronics playing nicely?

Off-Road Ranger I

Thanks! No worries about dubious Rover wiring because I'm rewiring it all, thankfully really easy when your engine is all mechanicalThis is an awesome build thread! Keep us updated! I've always loved Disco's and I would kill to have the money/time to do my own diesel swap in a disco 2. Best part is these trucks won't rust out on you, but you will be fighting electronics for years to come... trade offs I suppose. Are you worried about any of the electronics playing nicely?

Off-Road Ranger I

Last week+ I've been hung up with one of a few sticking points that I was expecting to delay the swap along the way.

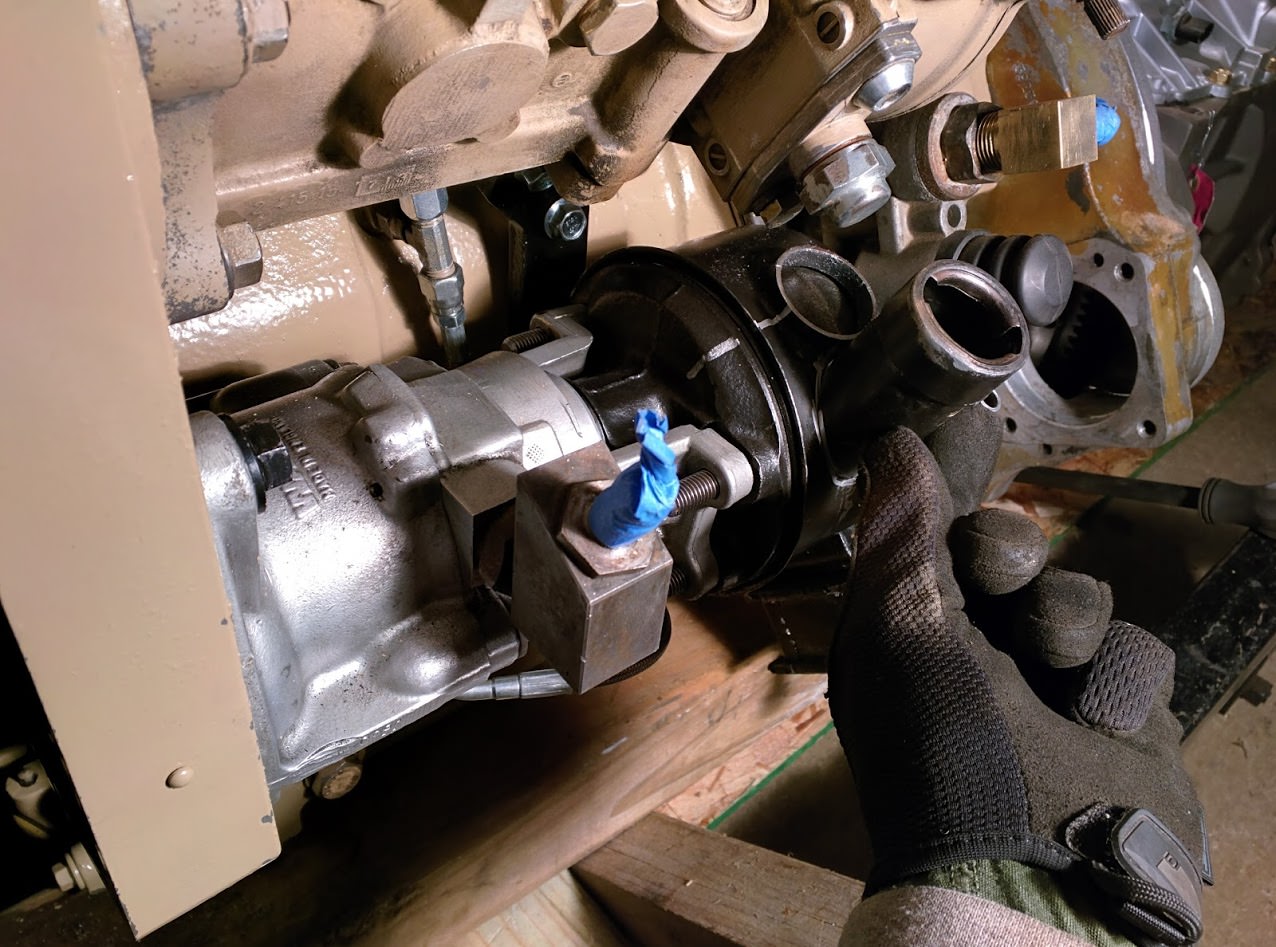

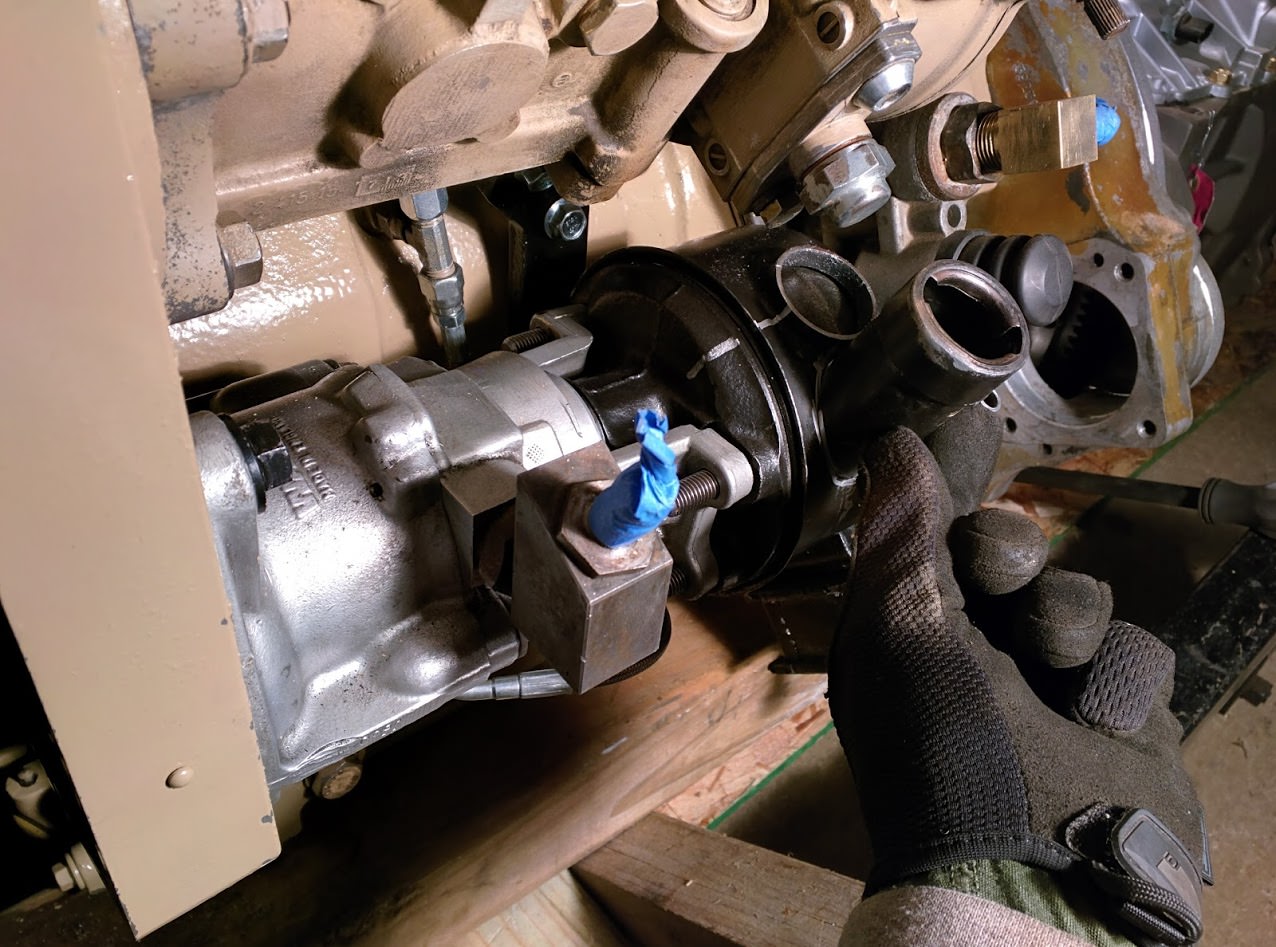

In this case I'm dealing with an interference between the vacuum pump, power-steering pump, starter, & drivers side engine mount. Not as bad as it sounds, so far I've found a solution for everything except the starter being too close to the mount. Although I do think I have a fix for that in the form of a "clockable" gear-reduction starter.

My vacuum pump / power-steering pump combo unit comes from the 6-cylinder engines & can be a tricky fit. Nothing that a bit of cut 'n weld can't fix!

At first I tried to pie-cut the fill neck:

Was still too close to the injection pump & hack looking for my taste:

No welding just yet though, best to wait & be sure it won't interfere with the steering. Here's a much better fit + angle with the reservoir cap'd off & the filler neck relocated lower like so:

And this illustrates the tight quarters I'm fitting a starter into:

Next up... test fitting the engine & trans!

Can't wait to get a look at it in there

In this case I'm dealing with an interference between the vacuum pump, power-steering pump, starter, & drivers side engine mount. Not as bad as it sounds, so far I've found a solution for everything except the starter being too close to the mount. Although I do think I have a fix for that in the form of a "clockable" gear-reduction starter.

My vacuum pump / power-steering pump combo unit comes from the 6-cylinder engines & can be a tricky fit. Nothing that a bit of cut 'n weld can't fix!

At first I tried to pie-cut the fill neck:

Was still too close to the injection pump & hack looking for my taste:

No welding just yet though, best to wait & be sure it won't interfere with the steering. Here's a much better fit + angle with the reservoir cap'd off & the filler neck relocated lower like so:

And this illustrates the tight quarters I'm fitting a starter into:

Next up... test fitting the engine & trans!

Can't wait to get a look at it in there

Off-Road Ranger I

Thanks! Those were on my original list of options & a close tie for 2nd place with LS V8's.Sweet build! Why did you not won't to swap a 300tdi or TD5? I'd love a diesel swap for the fuel range and torque.

My main reasons for choosing the 4BT over those were:

1) Simplicity - Hard for any other option to compete with a mechanical diesel ;)

2) Reliability - Another advantage that's hard to compete with, they're million-mile engines.

3) Torque - Heaps of it from pretty much idle rpm & plenty of "headroom" for more.

4) Parts availability - 4BT parts are surprisingly easy to find from so many sources (automotive, industrial, construction, commercial, power generation, etc) anywhere in the world thanks to Cummins being so widespread. I think there's only 5 countries they are NOT in!

Off-Road Ranger I

Updates! Sadly the Rovers radiator core-support is not removable... best course of action is chop it out of the way & make it bolt-in like it should've been. All the extra access is well worth the effort for what's next:

Needed access to the tunnel so the center console & it's spiderweb of wire got the boot:

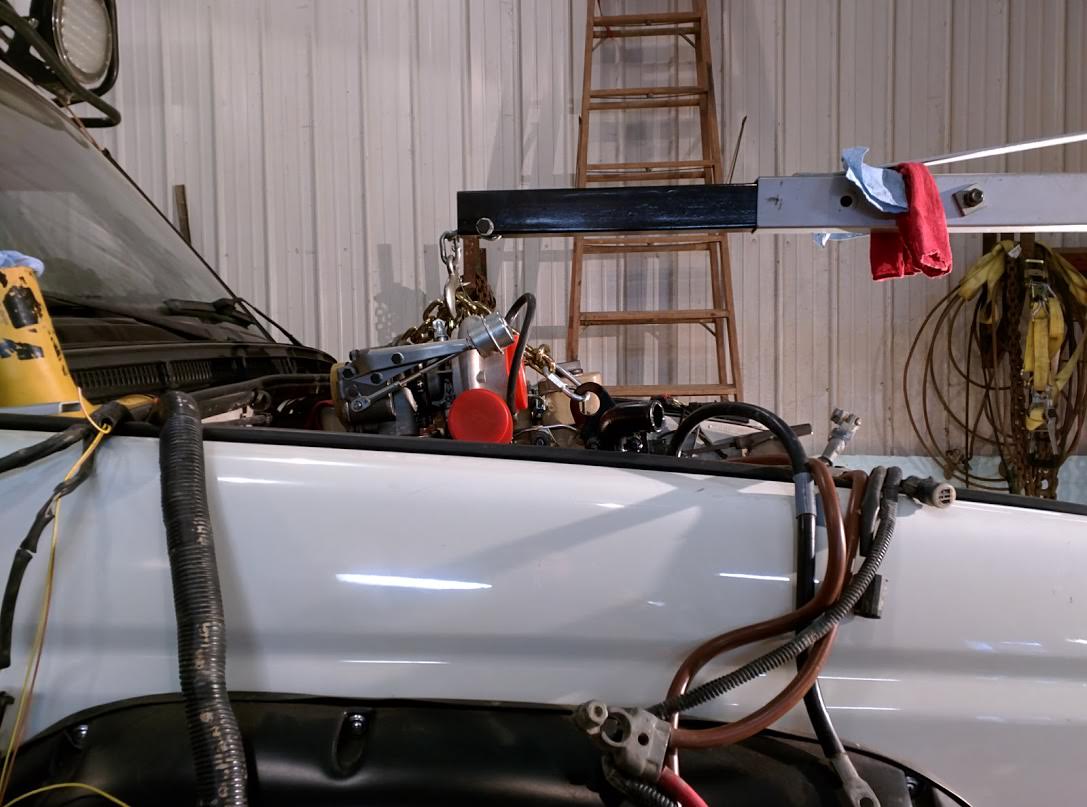

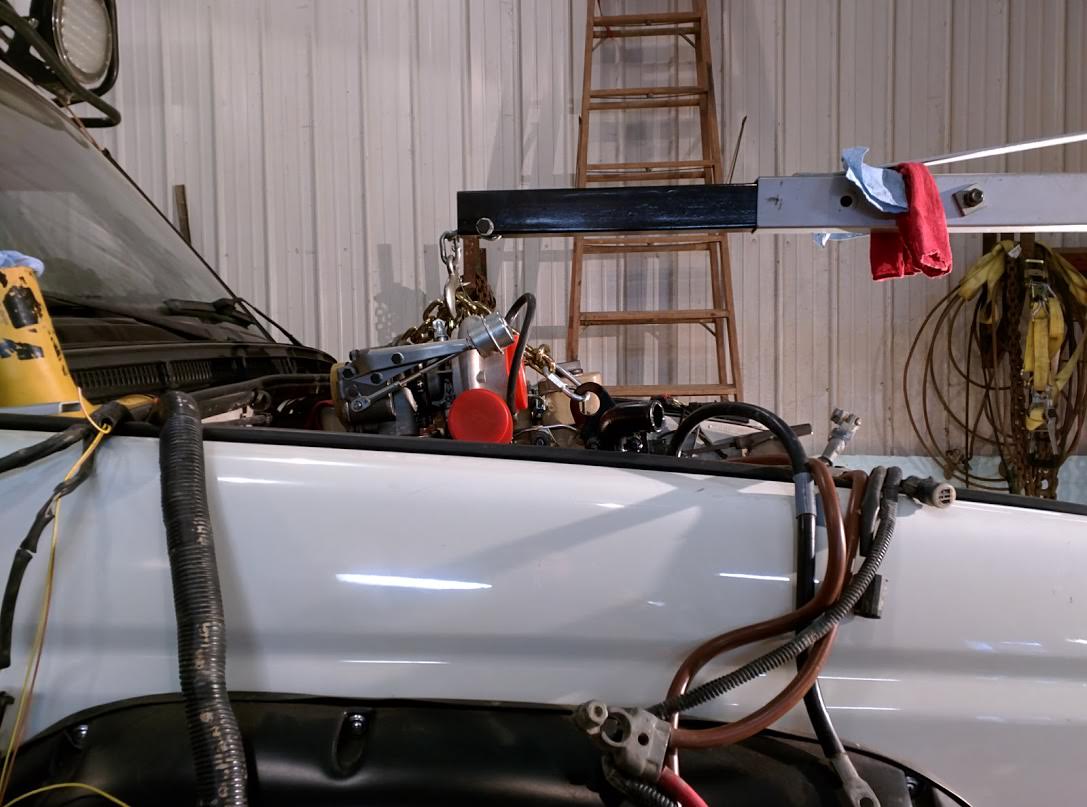

FINALLY test fitting time!!! Oh & I've acquired some of this newfangled "heat" stuff I've heard so much about:

No drama with that core-support cleared out:

Starting to look right at home, & not a bad fit at all! Going to leave me even more space in the bay then I expected:

Looks like the only thing I have to contend with is what I was already expecting... finding a balance of engine alignment between an interference point on each side. First being the timing cover's proximity to the steering gearbox, & second the oil sump's proximity to the differential:

It still can drop & slide back a bit more, but this initial test fit answered all the questions I had. Although, unsurprisingly, a cowl hood modification may be in my future. It's no short engine, even more so with the top mount turbo:

Needed access to the tunnel so the center console & it's spiderweb of wire got the boot:

FINALLY test fitting time!!! Oh & I've acquired some of this newfangled "heat" stuff I've heard so much about:

No drama with that core-support cleared out:

Starting to look right at home, & not a bad fit at all! Going to leave me even more space in the bay then I expected:

Looks like the only thing I have to contend with is what I was already expecting... finding a balance of engine alignment between an interference point on each side. First being the timing cover's proximity to the steering gearbox, & second the oil sump's proximity to the differential:

It still can drop & slide back a bit more, but this initial test fit answered all the questions I had. Although, unsurprisingly, a cowl hood modification may be in my future. It's no short engine, even more so with the top mount turbo:

Off-Road Ranger I

Off-Road Ranger I

Finished preparing my power steering reservoir modifications. The cap I made up for the old fill stem, & the new hole for the relocated stem, ready for welding:

Stock engine mount perches & everything else along the frame's now cleared out of the way:

Might try & machine up some new housings for my starter, so I can lose some length & set it up to "clock" however I may need:

Just needs a 90-degree rotation & maybe a 1/2" less length to fit... so close!

Stock engine mount perches & everything else along the frame's now cleared out of the way:

Might try & machine up some new housings for my starter, so I can lose some length & set it up to "clock" however I may need:

Just needs a 90-degree rotation & maybe a 1/2" less length to fit... so close!

Off-Road Ranger I

Holiday's are over & I'm back at it!

First order of business is tackling the interferences stopping me fabricating my engine mounts. The fun part, brainstorming ways to make things work where they shouldn't

Even though I could shoehorn the engine between the frame rails as is... the giant Rover steering gear is just too big to do so without it all ending up well off center. Had planned to upgrade the thing sometime in the future so it's no huge loss to chuck it & get my hands on a different gear that I'll mount up later. Here the engine sits even 2" off center & the timing cover is still a touch too cozy with the gear:

This grimy thing's plenty stout right out of the Land Rover factory, but I need the real estate & that means a gear that bolts to the outside of the frame rail is in order. Best option's looking like a steering gear from an old Scout-II or an 80-series Land Cruiser. After the mix of all sorts of brands that are going into the recipe for this project... why not a pinch of International or a dash of Toyota too? Will certainly be easier to find parts this side of pond too.

Hey there we go! Plenty of space to work with now! Engine's nicely centered & the positioning's good in respect to the rear output, transfer case, shift lever, radiator clearance, turbo downpipe routing. Oil pan is still kinda close to the front differential, going to cycle the suspension to be double sure. Also definitely will be building a cowl into the hood to clear the turbo, intake horn, & valve covers:

Next up is the starter getting in the way of... well... just about everything on the drivers side:

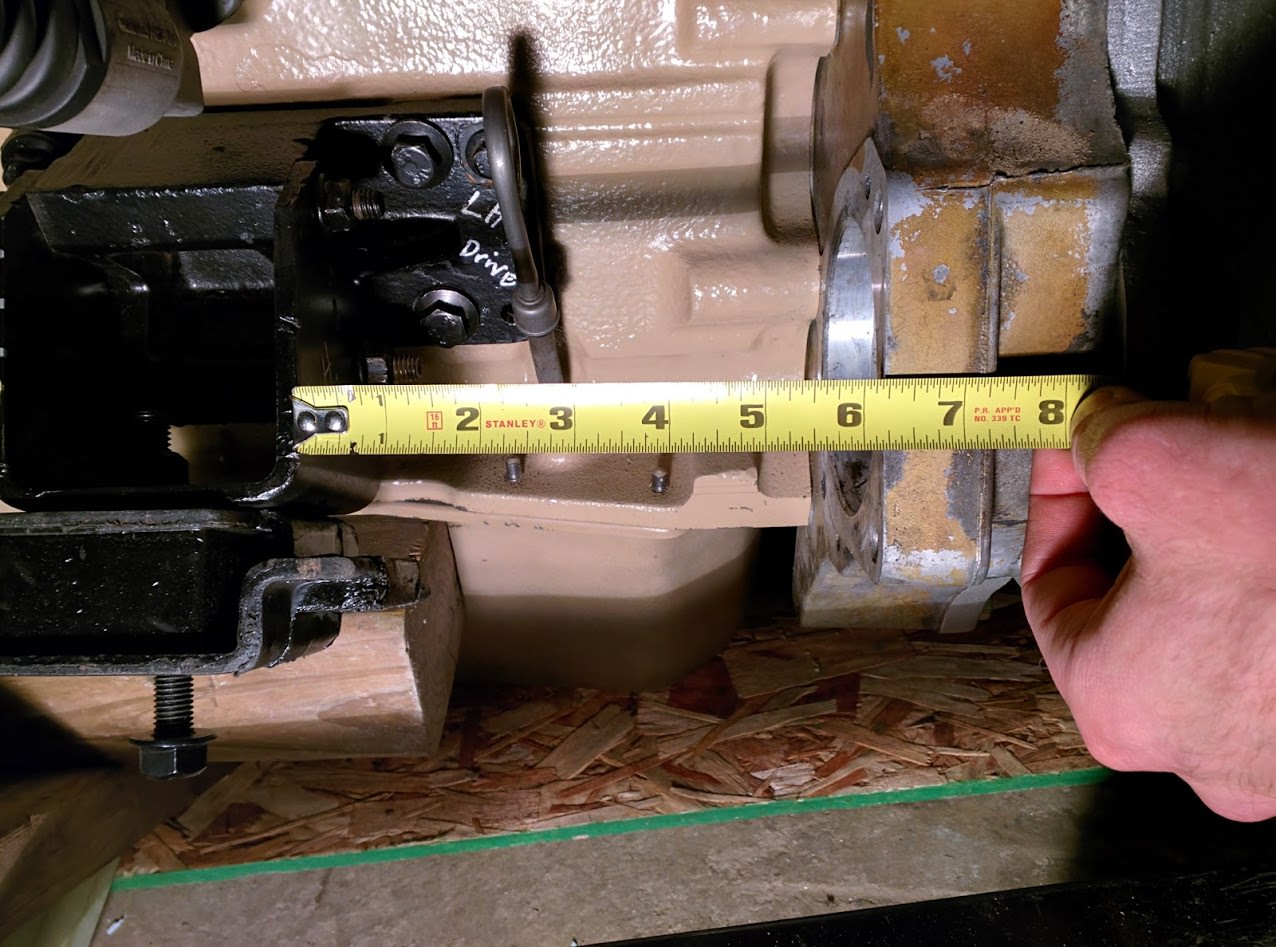

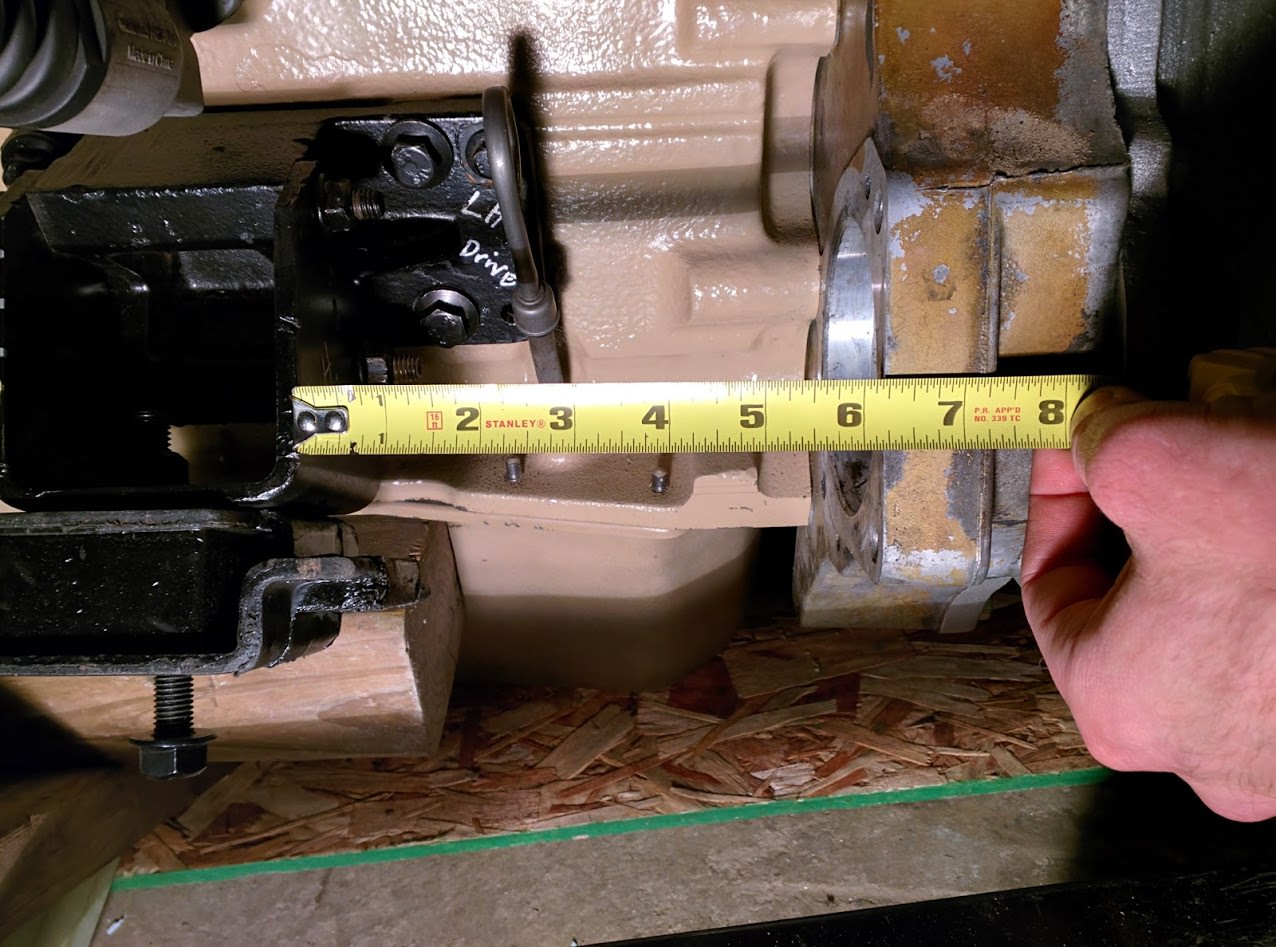

After loads of head scratching & measuring I think I've come up with a plan with the help of a friend who shares my penchant for unique projects like this. Rotating the starter a bit will save me from moving the engine mount away from the ideal location (for the sake of weight balance & vibration). Won't require me chopping up the engine mount anywhere near as bad as I thought:

I'll be adding aluminum to all 3 ears of the starter housing as the rotation has the bolts now roughly an inch out of place. Going to build it up with TIG weld & bore 3 new holes thru the added material to line back up with the original mounting bosses.

Need to take the engine adapter (that the starter bolts to) with me to verify the modifications... so apart it comes! Getting good practice at this, be able to do it blindfolded in no time haha! Once I've got the starter mods sorted I can get the whole lot back between the frame rails to build my engine & trans mounts. VERY MUCH looking forward to the milestone of having it all resting in there without the aid of hoist/lift/stand etc.

First order of business is tackling the interferences stopping me fabricating my engine mounts. The fun part, brainstorming ways to make things work where they shouldn't

Even though I could shoehorn the engine between the frame rails as is... the giant Rover steering gear is just too big to do so without it all ending up well off center. Had planned to upgrade the thing sometime in the future so it's no huge loss to chuck it & get my hands on a different gear that I'll mount up later. Here the engine sits even 2" off center & the timing cover is still a touch too cozy with the gear:

This grimy thing's plenty stout right out of the Land Rover factory, but I need the real estate & that means a gear that bolts to the outside of the frame rail is in order. Best option's looking like a steering gear from an old Scout-II or an 80-series Land Cruiser. After the mix of all sorts of brands that are going into the recipe for this project... why not a pinch of International or a dash of Toyota too? Will certainly be easier to find parts this side of pond too.

Hey there we go! Plenty of space to work with now! Engine's nicely centered & the positioning's good in respect to the rear output, transfer case, shift lever, radiator clearance, turbo downpipe routing. Oil pan is still kinda close to the front differential, going to cycle the suspension to be double sure. Also definitely will be building a cowl into the hood to clear the turbo, intake horn, & valve covers:

Next up is the starter getting in the way of... well... just about everything on the drivers side:

After loads of head scratching & measuring I think I've come up with a plan with the help of a friend who shares my penchant for unique projects like this. Rotating the starter a bit will save me from moving the engine mount away from the ideal location (for the sake of weight balance & vibration). Won't require me chopping up the engine mount anywhere near as bad as I thought:

I'll be adding aluminum to all 3 ears of the starter housing as the rotation has the bolts now roughly an inch out of place. Going to build it up with TIG weld & bore 3 new holes thru the added material to line back up with the original mounting bosses.

Need to take the engine adapter (that the starter bolts to) with me to verify the modifications... so apart it comes! Getting good practice at this, be able to do it blindfolded in no time haha! Once I've got the starter mods sorted I can get the whole lot back between the frame rails to build my engine & trans mounts. VERY MUCH looking forward to the milestone of having it all resting in there without the aid of hoist/lift/stand etc.

Off-Road Ranger I

Got a friend's help with a Bridgeport mill & a proper TIG welder to get my starter & engine mount bracket modifications done. I think some of these images of my modifications might not make a ton of sense until I get shots of it all assembled... but I was slacking a bit on posting so here we go!

Rotating the starter up towards the lift pump (away from the frame rail & engine mount) required a new set of bolt holes. The new upper bolt location would interfere with the starter's motor so we had to add this threaded boss onto the engine plate:

For the side & lower bolts I'm able to utilize the original threaded holes in the engine plate. And on the starter housing we added new "ears" to match the rotation needed. This way the starter pinion stays centered in the bore, also the meshing with the flywheel stays in tolerance. Here it is with all the guts removed & bolted to the engine plate, note the original 3 bolt holes alongside the black-oxide bolts:

The engine block side of the mount on the drivers side needed some love too. I needed to lose a 1/2" on the casting & plate to clear the length of the gear reduction part of the starter, which still leaves plenty of real estate for the rubber isolator to rest on. For fear of vibration causing things bumping into one another I decided to cut a few clearances in the plate that I'll box in later (a pair of radii & a hole). Here you can see it assembled after all the cutting, before we welded it up & bored new isolator holes:

After I get it all reassembled I'm hoping to start welding mounts to the frame within the week!

Here's a clip I put together of measuring & working out of the plan for these modifications, next one I'll put together will have the fabrication of 'em.

Rotating the starter up towards the lift pump (away from the frame rail & engine mount) required a new set of bolt holes. The new upper bolt location would interfere with the starter's motor so we had to add this threaded boss onto the engine plate:

For the side & lower bolts I'm able to utilize the original threaded holes in the engine plate. And on the starter housing we added new "ears" to match the rotation needed. This way the starter pinion stays centered in the bore, also the meshing with the flywheel stays in tolerance. Here it is with all the guts removed & bolted to the engine plate, note the original 3 bolt holes alongside the black-oxide bolts:

The engine block side of the mount on the drivers side needed some love too. I needed to lose a 1/2" on the casting & plate to clear the length of the gear reduction part of the starter, which still leaves plenty of real estate for the rubber isolator to rest on. For fear of vibration causing things bumping into one another I decided to cut a few clearances in the plate that I'll box in later (a pair of radii & a hole). Here you can see it assembled after all the cutting, before we welded it up & bored new isolator holes:

After I get it all reassembled I'm hoping to start welding mounts to the frame within the week!

Here's a clip I put together of measuring & working out of the plan for these modifications, next one I'll put together will have the fabrication of 'em.

Hey Tinker--you may already know this, but make sure the oil cooler is from a 4BT, as 6BT's and 4BT's are ported different, so you starve some galley's if you swap them. We did a Range Rover 4BT. ended up using a P38 steering box outboard of the frame to clear the front cover. Cool conversion when it's done though. Used a Diesel Conversions 4500 to t-case adapter to shorten the package--that dang shift is really close to the dash. Cool rig man, I'm anxious to see that thing up and running!!!Managed to find a salvage power steering & vacuum pump combo that fits right into the front cover, will keep me from having to convert to hydroboost brakes:

I love how many parts from the Dodge trucks & myriad of industrial applications fit this engine! Found a salvage oil cooler plate that mounts the filter vertical instead of horizontal (messy oil changes!) like the step van had:

I'm coming to the realization that I may need bigger/stronger tools... everything on this engine is HUGE. Broken a few things already:

And I discovered this terrifying "Killer Dowel Pin" (a known Cummins issue) that I found halfway wandered out into the timing cover: