Ok, weekend summary time! After going back out to the garage Saturday morning and being pleasantly surprised by the engine still being in the truck, I decided to try to get it to a point where I can test fire it. This will require putting on the intake, hooking up all of the electrical bits, plumbing a fuel system, and figuring out what exactly the computer needs to see.

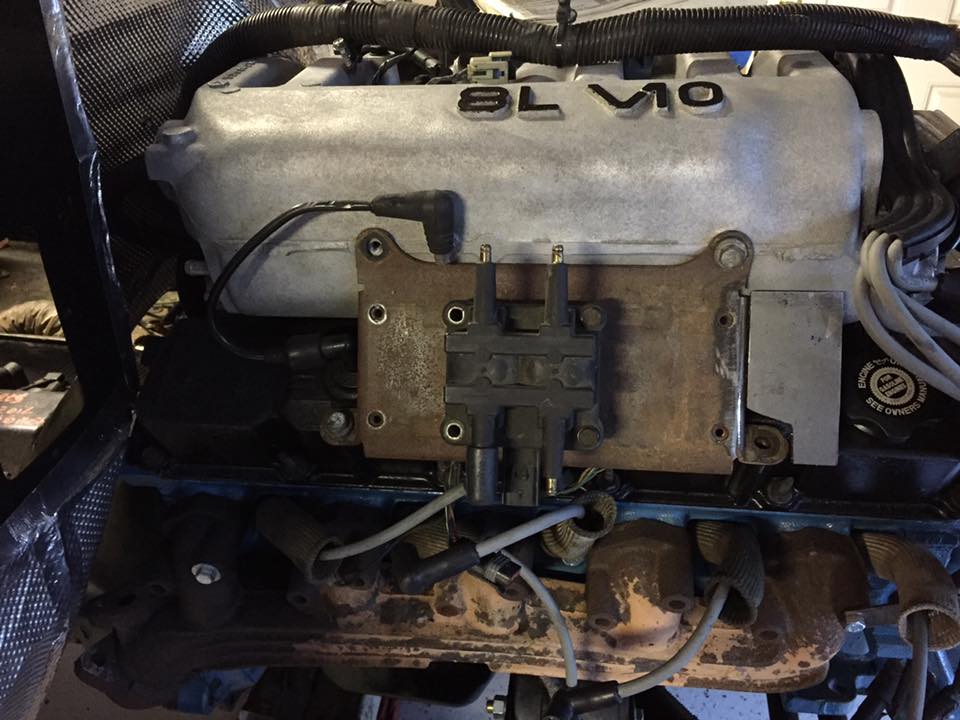

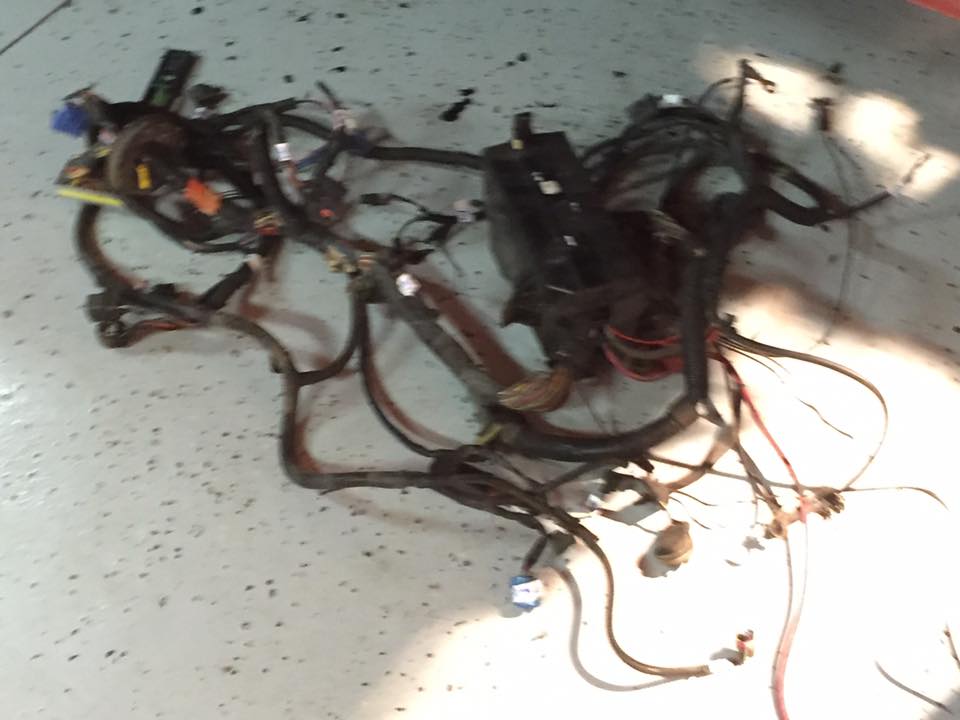

It started out easy enough. I installed the upper intake manifold and draped the engine wring harness over it. Everything was plugging in easy enough and looking good. But when I brought over the rest of the harness, my head just started to spin. I’m note great at wiring and the last time I did a whole car, I let the smoke out a couple times… So I sat and stared at it for a while to figure out my way forward. I think it will be best to go through all of my diagrams and schematics to determine which wire is which and label them all. There’s a lot in the dodge harness that I don’t need (it’s lights really) but I do need the gauges, sensors, sending units, etc.

After determining that that was going to take a lot of work, I shifted gears to the fuel tank. My thought was to graft the top of the Dodge tank onto the 715 tank so I can use exactly what the V10 is expecting. I had assumed there would be a lot of flat surface area on the Dodge tank around the fuel system drop-in. There was not. After I was done cutting away everything, there’s not a lot left. I’m not sure that I’ll be able to do it now. I’m going to ask some people at work. Maybe they’ll have a good idea for a way forward.

the donor tank

top removed

guesstimating placement

and all that's left after trimming...

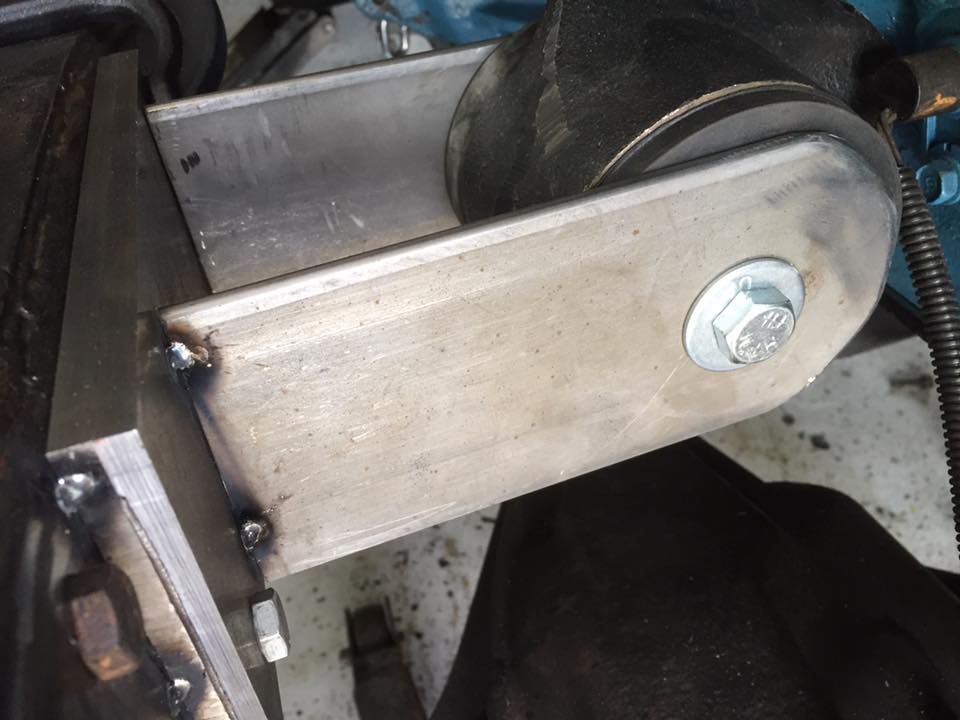

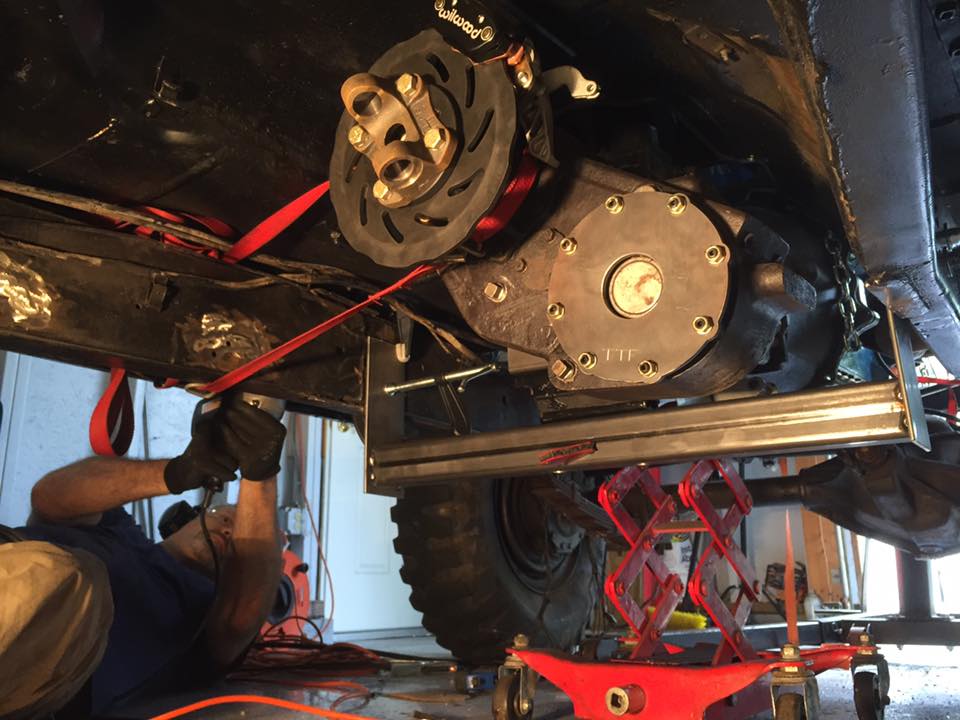

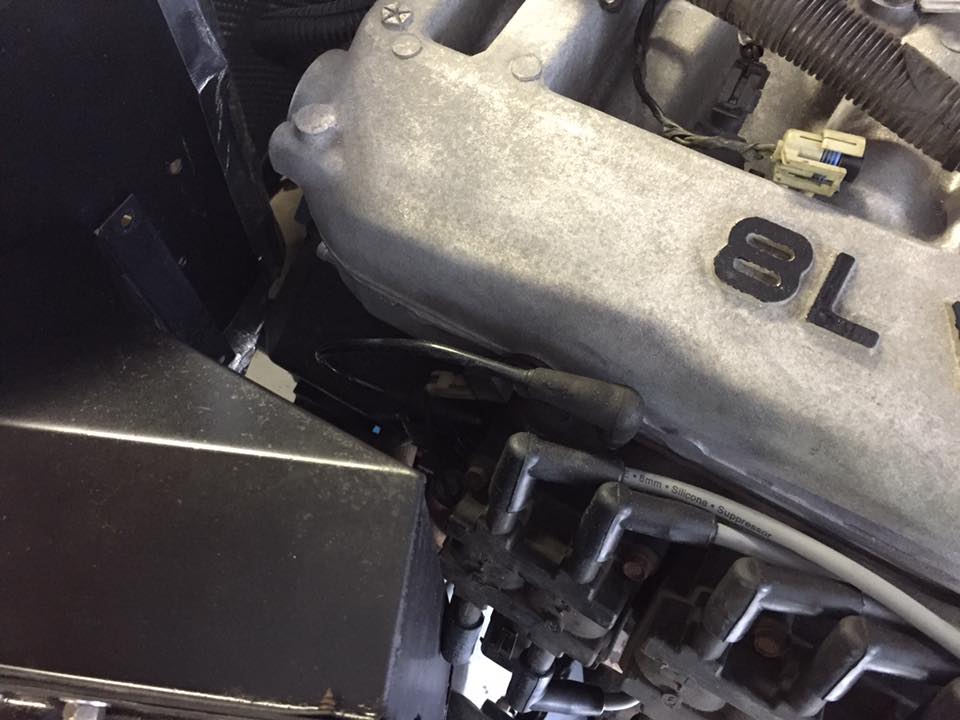

When that roadblock surfaced, I changed gears again to redoing the heater box. It was pretty humid yesterday so the paint may not have come out the best, but it looks better. I gave it a new, non-leaking, heater core and slapped it back together. When I went to put it back on the truck, I found out that it interferes with the coil packs. So now I’m fabricating a mount to move them forward 2”. If it’s not one thing it’s another right?

painting all of the heater box pieces

reassembled. Not too shabby!

And the coil pack interference

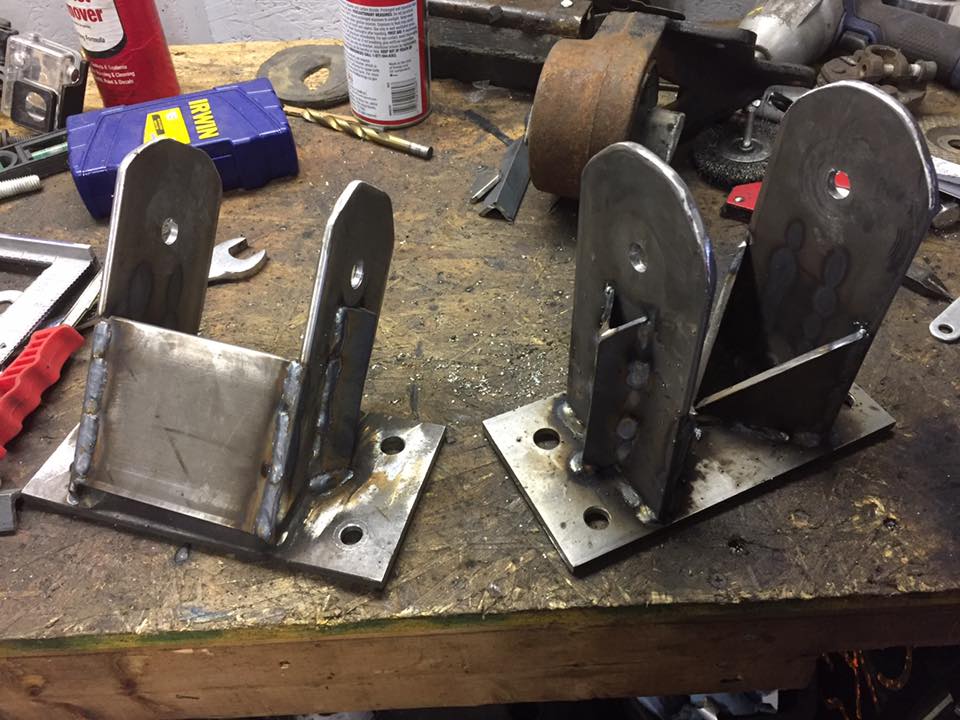

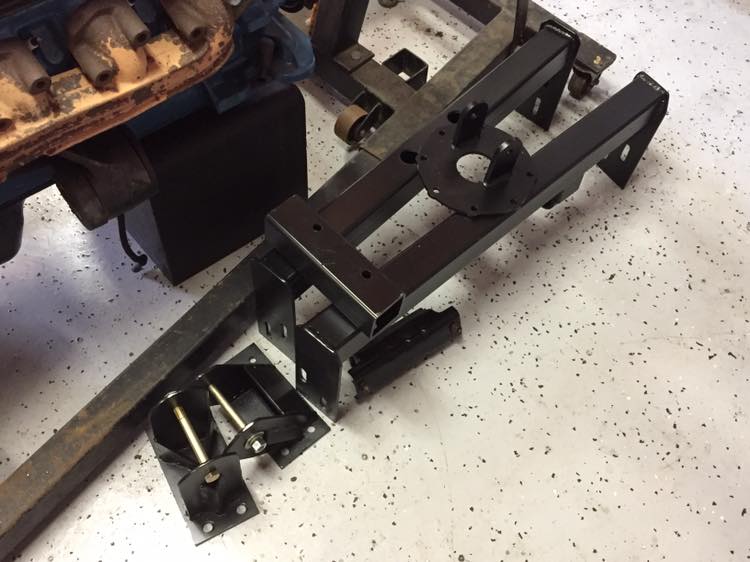

starting to modify my spare bracket to move the coil packs 2" forward

So hopefully I’ll at least get my coil packs relocated today/tomorrow and I can start sorting all of the wires. I’ll worry about the fuel tank later.