Enthusiast III

Enthusiast III

Enthusiast III

Off-Road Ranger I

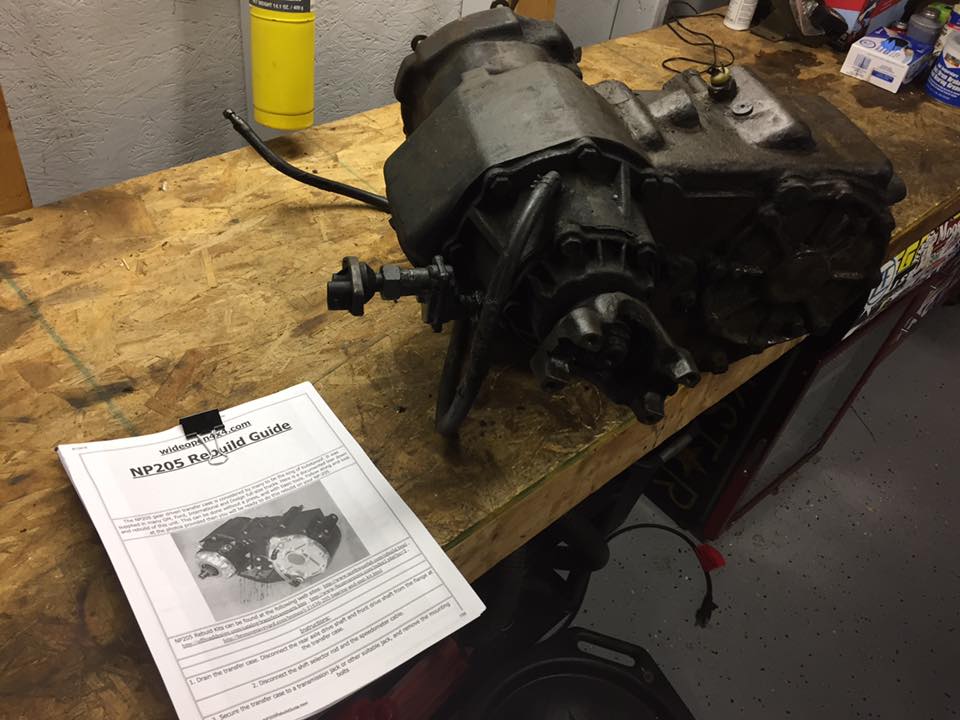

I don't think so. I think it just got caught between the input shaft and the bearing race. I think the shim shifted when I was installing the shaft and it acted like a hole punch.Is there a burr on there somewhere (case, bearing, gear, etc) that might've cut the shim? That is a surprisingly clean break on both sides of it!

Off-Road Ranger I

Ohhhh yeah I can see that now. Badass build by the way! I've had a soft spot for those trucks since I was a kid.I don't think so. I think it just got caught between the input shaft and the bearing race. I think the shim shifted when I was installing the shaft and it acted like a hole punch.

Thanks man!Ohhhh yeah I can see that now. Badass build by the way! I've had a soft spot for those trucks since I was a kid.