_________________________________________________________________________________

Hello OverlandBound!

This will be my thread for listing and explaining my current and future mods to my Subaru Forester '18 XT. Stock, it runs with a 2.0L FA20F Boxer engine with 250 hp, 258 ftlbs of torque. Weight comes in at 3,296 lbs, with a 104" wheelbase and about 1 ft. of ground clearance with my ADF lift. With Subaru's excellent AWD system, I've never really had much trouble except in mud deeper than 1 ft. This thing is a beast in snow!

_________________________________________________________________________________

Mod List

Exterior

_________________________________________________________________________________

Current Photos

Thanks for looking!

Hello OverlandBound!

This will be my thread for listing and explaining my current and future mods to my Subaru Forester '18 XT. Stock, it runs with a 2.0L FA20F Boxer engine with 250 hp, 258 ftlbs of torque. Weight comes in at 3,296 lbs, with a 104" wheelbase and about 1 ft. of ground clearance with my ADF lift. With Subaru's excellent AWD system, I've never really had much trouble except in mud deeper than 1 ft. This thing is a beast in snow!

_________________________________________________________________________________

Mod List

Exterior

- ADF 2" front lift, 2.5" rear lift

- DIY fab'ed swing-out steel bumper for spare tire and gas cans

- 30W hood-mounted solar panel

- Gorilla Offroad mudflaps

- Falken AT3W Wildpeak tires (215 65R 17)

- 17" steel wheels

- DIY extruded aluminum roofrack (using 80/20).

- 7" 51w flood lights

- X-BULL traction boards

- DIY axe carrier

- LiFePo4 auxillary battery (12v, 38Ah).

- DIY cabinet/desk (spalted maple and pine).

- DIY storage compartments with tie-down points (spalted maple doors).

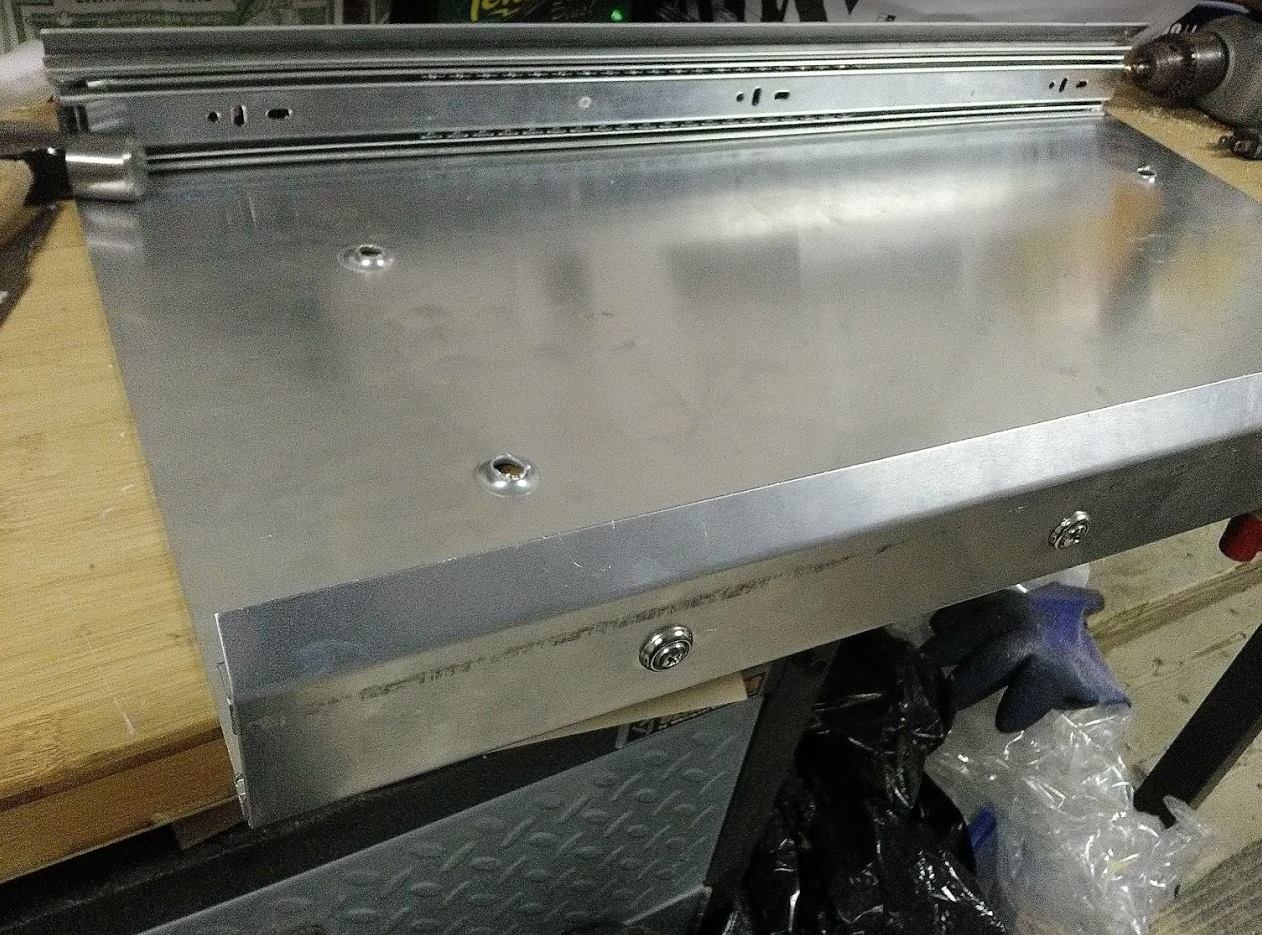

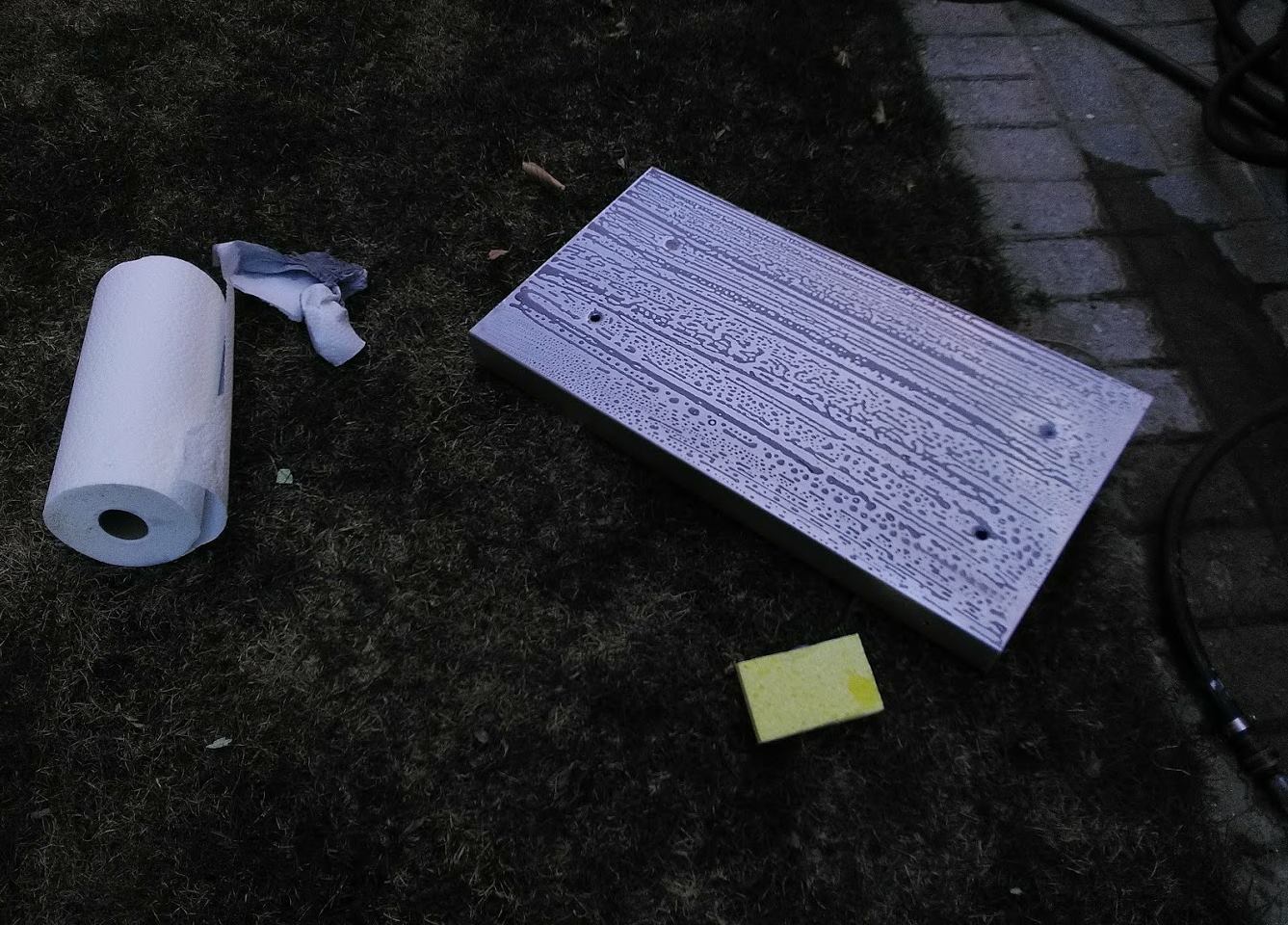

- DIY aluminum nested slide-out tables (large with 70 lb capacity, small 50 lb).

- Isobutane stove

- Spray nozzle/shower

- Sink

- 20L water tank

- 110v UV water filter

- 1.2 GPM 35 PSI diaphragm pump

- 110V 750W inverter

- Dual battery system (with dual 80A breakers).

- 110v outlets (2)

- 12v outlets (5)

- 5v USB outlets (2)

- Fire extinguisher

- First-aid kit

- Better skid plate

- Brush bar

- Winch mount

_________________________________________________________________________________

Current Photos

Thanks for looking!

Attachments

-

966.8 KB Views: 13

-

1,016.7 KB Views: 12

Last edited: