Traveler II

The time has come for me to pull the RTT and awning off of my Land Cruiser and permanently attach them to a trailer...a trailer that is always ready to go!

Objective: Have a trailer that is always ready for adventure.

Goals:

I went to check it out, negotiated a bit and proceeded to drag it home. My anxiety was sky high at the thought of dragging a trailer 80 miles home (in the rain) with no fenders, lights or knowledge of how the bearings looked.

The back way home took me through some of my favorite parts of Kansas.

I made it home with out incident. The hubs were nice and cool

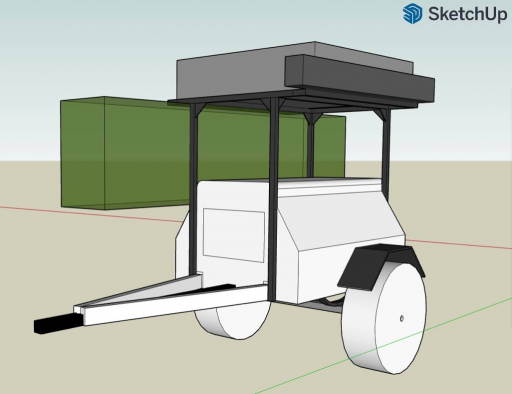

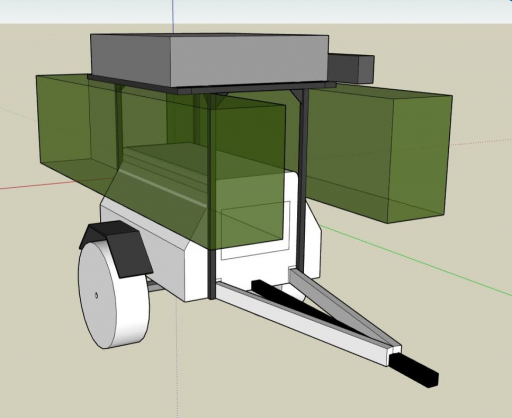

This is my arm chair plan for 'Yeller' the trailer:

Objective: Have a trailer that is always ready for adventure.

Goals:

- Small cargo trailer that gear can be permanently stored in

- Water tight construction

- Have the ability to haul two kayaks

- Hold a RTT and awning high enough so that I can walk under without ducking

- Have the ability to mount my fridge on a slide

- Tongue that allows for 90° jackknife

- Run dedicated trailer 30/31" tires and spare to allow use behind a TJ or Land Cruiser

- Allow for [future] electrical system expansion

- Allow for [future] permanent mount water tank

I went to check it out, negotiated a bit and proceeded to drag it home. My anxiety was sky high at the thought of dragging a trailer 80 miles home (in the rain) with no fenders, lights or knowledge of how the bearings looked.

The back way home took me through some of my favorite parts of Kansas.

I made it home with out incident. The hubs were nice and cool

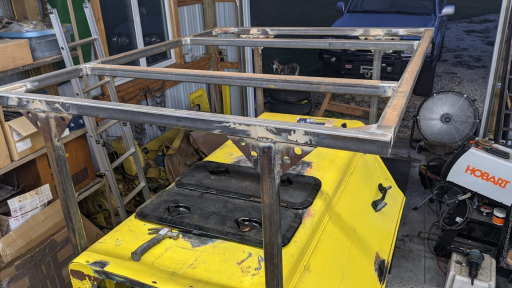

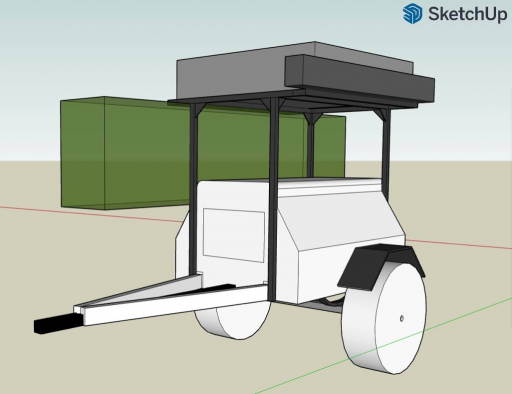

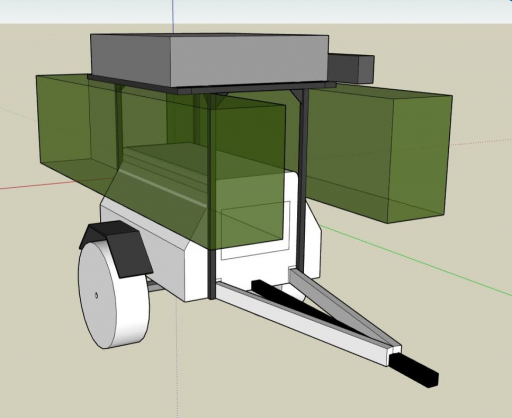

This is my arm chair plan for 'Yeller' the trailer:

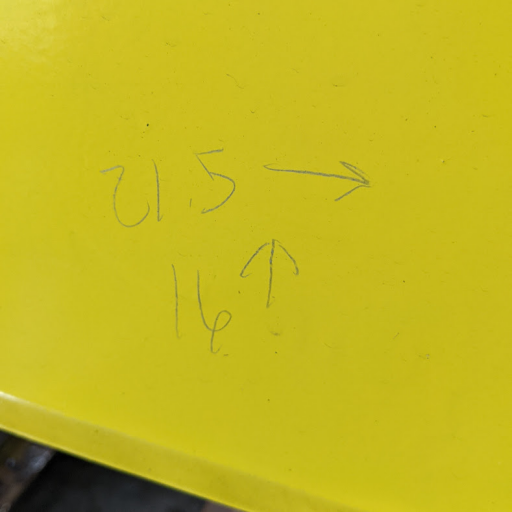

- Relocate axle under the tub at 60/40

- SOA and shocks with 235/75R15 tires

- 2-1/2x2-1/2x0.25 hitch 'backbone' with receivers at the front and rear

- 1-1/2x1-1/2x0.1875 rack structure

- The green boxes represent a kayak

- Awning and RTT height is 6' 6" from the ground

- Access doors front and year

- Weatherproof side flip up doors

- Paint (the yellow might go away, but the 'Yeller' never will)

Last edited: