Alright. Time to get this lift and tires post out of the way. Trying to catch this thread up to present, as I have mods I'm making this weekend and I can't wait to show those to you guys.

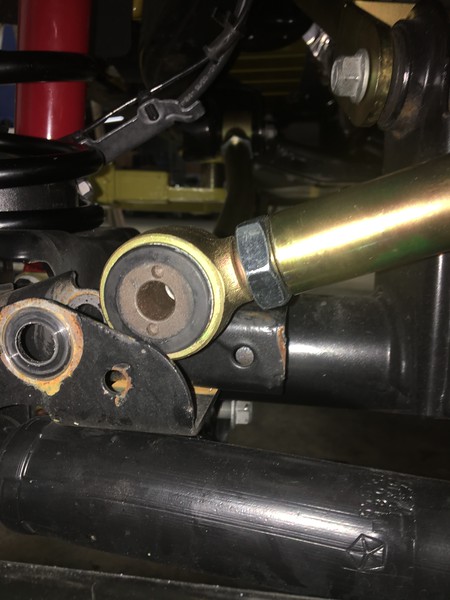

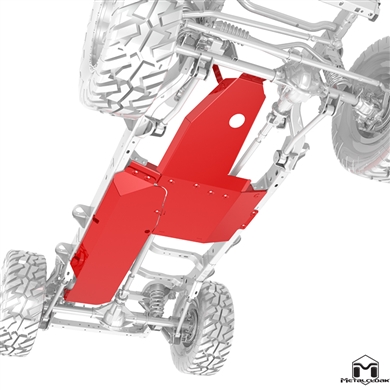

As stated, I decided to go with the 3.5" MetalCloak Game-Changer RockSport edition lift. It replaces the factory control arms and track bars with beefier adjustable control arms and track bars with that have been engineered for the Jeep's specific geometry. In terms of springs, it includes dual rate coil springs with shocks built by MetalCloak that have been tuned to their specific springs. Everything works in harmony. I like that. One of the other reasons I went this route was because the MetalCloak DuroFlex joint is low-maintenance, self-centering, and rebuildable. It allows for high degrees of misalignment when flexing and has a high level of vibration dampening as well. This all translates to a smooth ride. I was concerned about NVH (noise, vibration and harshness). I wanted to raise the vehicle to increase clearance, but at the same time I wanted to maintain a stock or better than stock ride quality, and that is what has been achieved.

I actually did the front end of the lift installation myself. It was quite the experience, as I had never done anything like that before in my life, and I don't exactly have the biggest tool collection in the world, especially for automotive work.

I found a place in Atlanta (Oloba Rennsport) that is a car club with a "clubhouse" - essentially you can pay a membership fee (monthly or yearly) and have access to their warehouse with two automotive lifts.

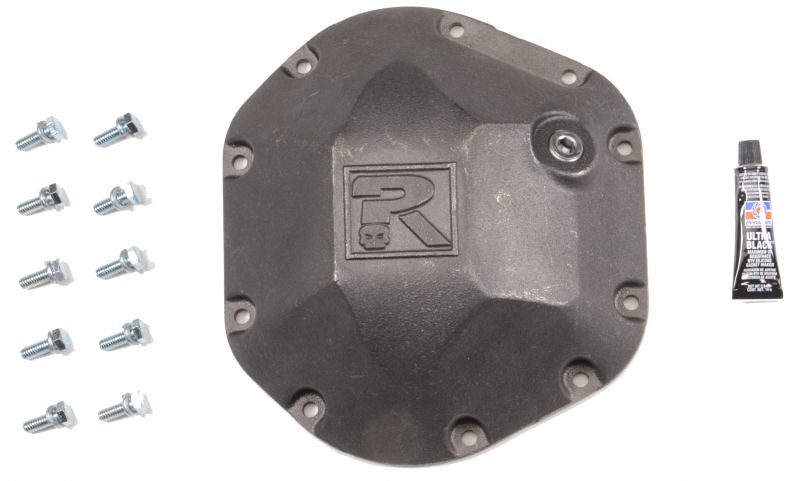

I started work around noon, taking my time doing the work. First, I swapped the stock sway bar links, then I got the stock springs and shocks out, and then moved on to installing the new shocks, springs, and bumpstops. Then I installed the extended brakelines, bled the brakes and, finally, swapped out the control arms and the track bar. Doing all of this with hand tools made the process slow going (and required some makeshift breaker bars).

New sway bar links installed

Bench full of parts!

Getting the beefier track bar in the axle side bracket and getting the axle centered was the biggest pain in the arse ever.

Front end is almost there!

About the time I was going to start the read, I got a phone call from a concerned girlfriend (now fiancée... still concerned about me, FWIW).

"Hey, what's up babe?" I said. "Where are you?" replied the concerned voice on the other end of the phone. "At that place, installing my lift, remember?" I said. "Jason, it is 6am," she said. "Huh?," I said, confused. "You didn't come home last night," she said. I couldn't believe it. Was it really 6am? No way. One look at my iPhone's clock verified what I heard on the phone.

And that's the story of how I spent 18 hours installing the front end of my suspension.

It was time to call in the professionals. I had taken the previous day off work, but I did not plan for a second day.

I packed everything up and gave the guys at the shop that did the welding work on the C gussets a call. They would be able to squeeze me in if I could get up to the shop ASAP! I drove the Jeep over to the shop, rocking the "Tennessee Tilt" (if you don't know what that is, try Google).

The guys at the shop, with their fancy air tools and full kitted toolboxes, made quick work of the rear suspension, and I was off to Discount Tire for the KO2s. Discount Tire got the 35" KO2s mounted to the new 17" AEV Pintler wheels, and I headed back to the shop for an alignment.

Guess what? The guys at the shop told me not only was the front end properly installed, it was perfectly aligned and caster / pinion angles looked great. Also the axle was perfectly centered up front! My hard work paid off!

Sent from my iPhone using

OB Talk