Over the last week we've done an overhaul on the 4runner. We started with cleaning up, and painting the entire frame including the gas tank skid. Next we paint the old 4xInnovations front bumper at the same time we painted the new 4xInnovations rear bumper. We'll we worked on the bumpers I pulled both rear shafts, ordered parts, and took them to a machine shop for new bearings to be installed. Once those were back we install new drums and shoes, and bled all four corners. Next was installing some CaliRaised LED pods on CBI ditch light brackets. Next came installing our ARB compressor, Blue Sea fuse, Blue Sea breaker, and switch on aluminum panel I made. Last night we finished the suspension by adding some Toytec Superflex springs, and today we finished with installing the bumpers.

Here's what I remembered to take pictures of along the way.

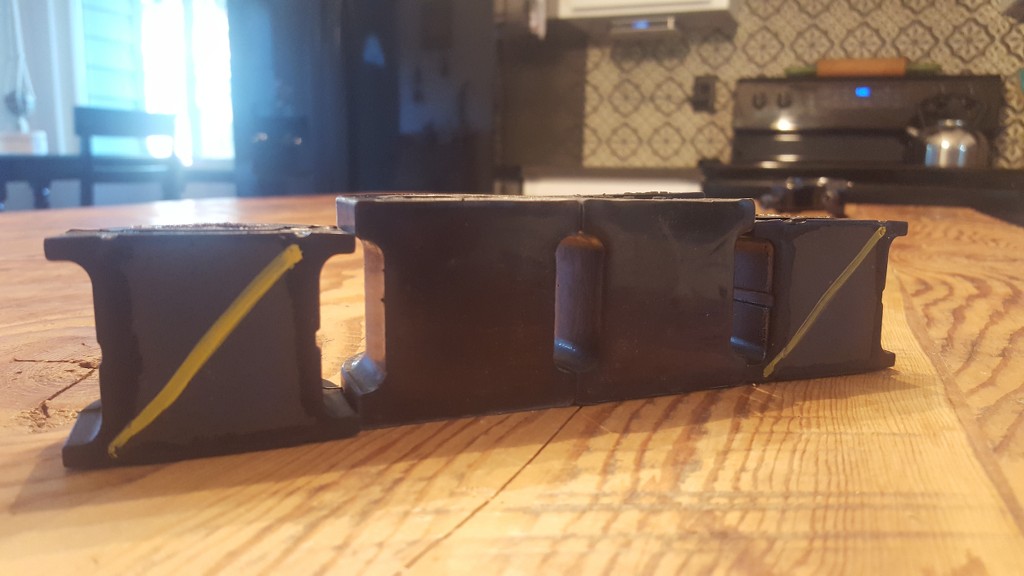

The newly painted frame. While we couldn't get everything we did the best we could given the time frame. We spend a good 8 hours wire wheeling, chipping, cleaning, and painting everything.

Next was installing the new bumpers. Both were painted with Herculiner due to availability to us, durability, and cost. The rear bumper has the optional fold down cooking tray.

Here's the fuse panel setup that we mounted to the driver side fender.

Here's the ARB compressor mounted to the passenger side wheel well.

I still need to put my RCI skids back on, swap the jerry can holder, mount the propane tank, put the shower on the roof, and pack. These plus more need to be done by noon on Friday.