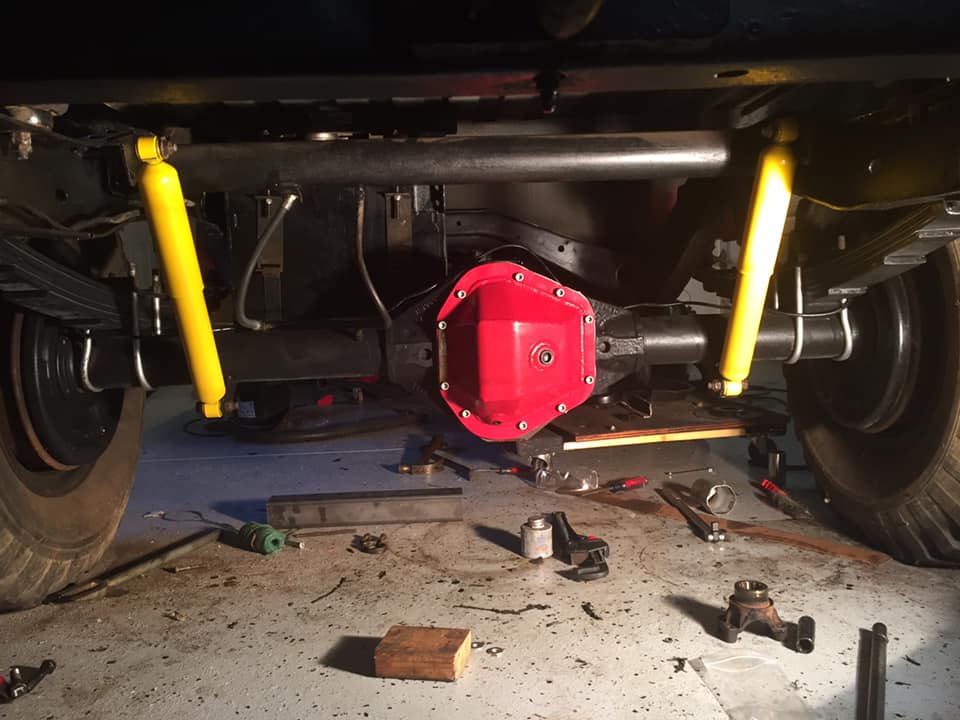

Ok, so I got the rear leafs back together and the shocks installed. It looks really good and now the rear of the truck moves a bit when you put weight on it!

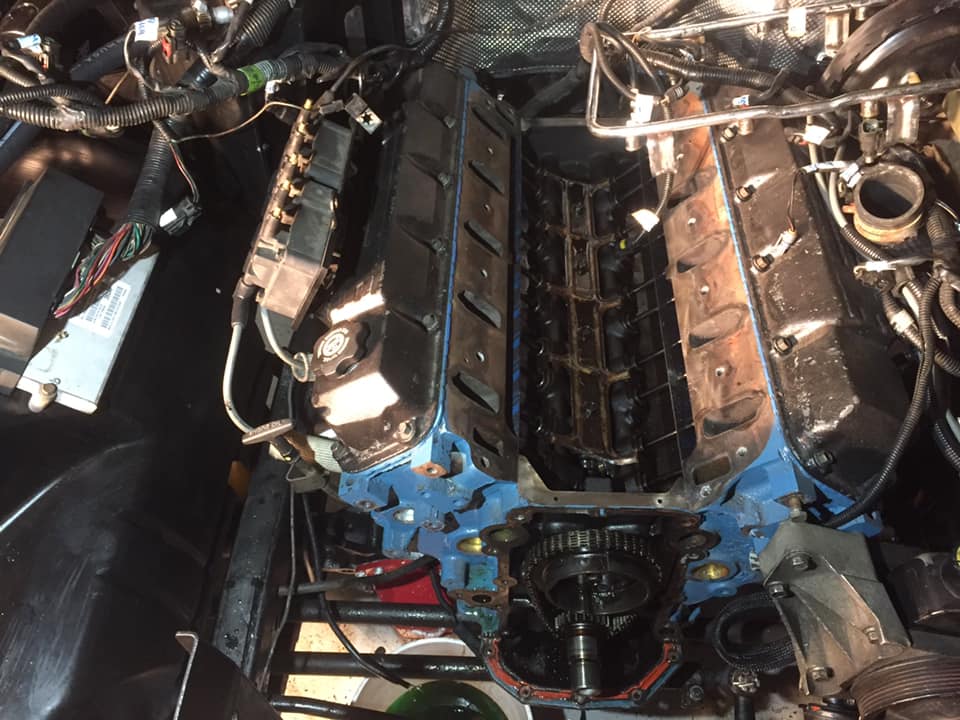

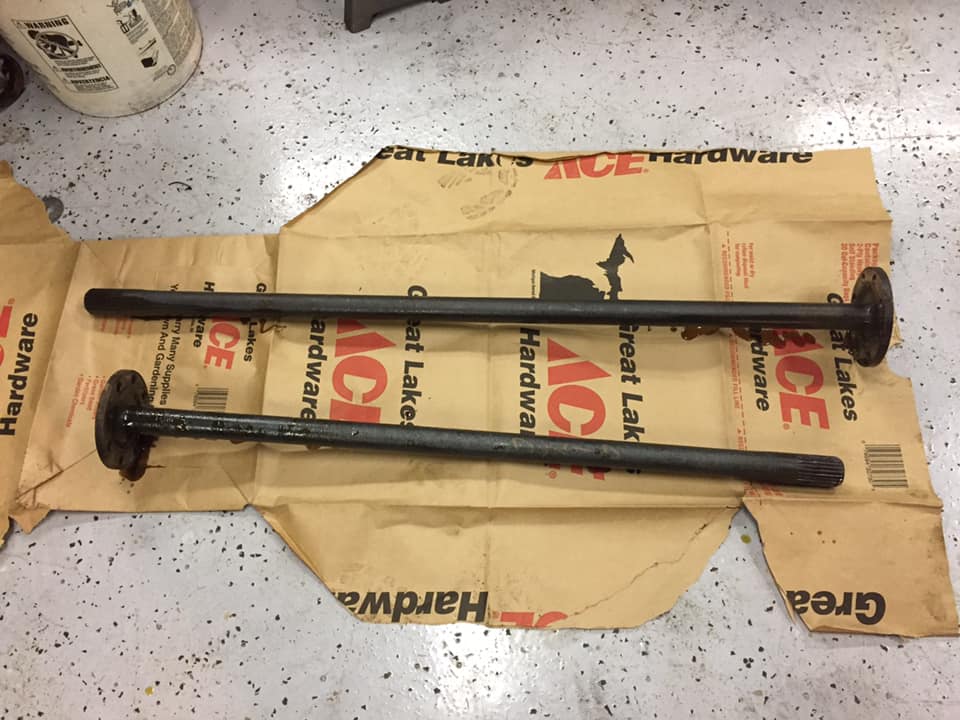

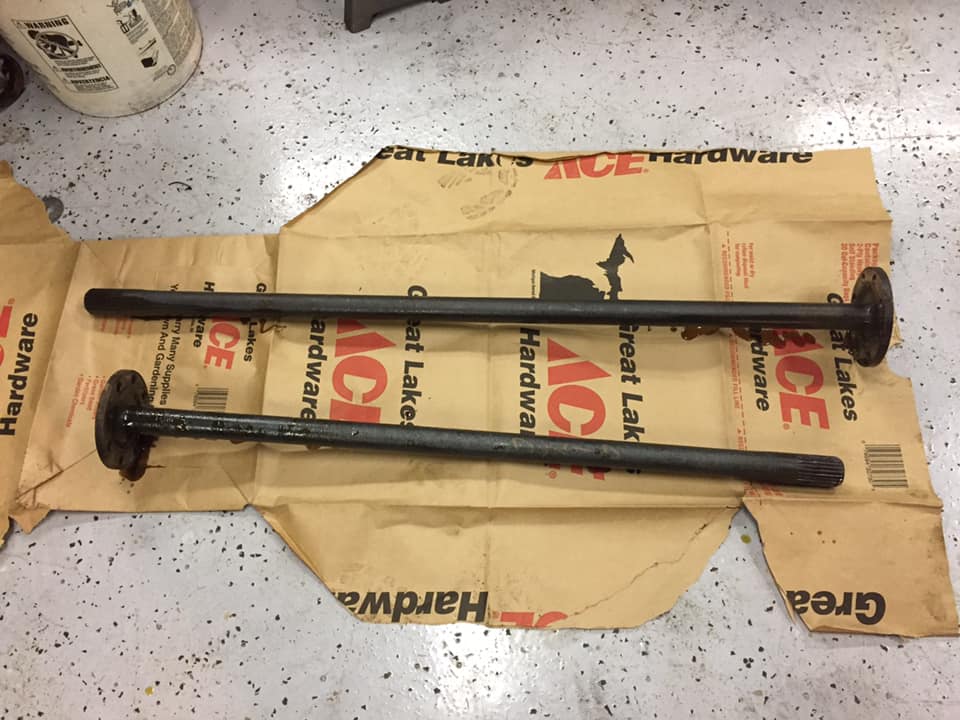

From here, I started to take the axle apart so I can install my Detroit locker and 1410 pinion (thanks to Treepusher's install guide). When removing the hub nuts from the studs, a handful of them pulled out. Oh well.

Other than that, I had just enough room between the truck and the garage wall to remove the shafts.

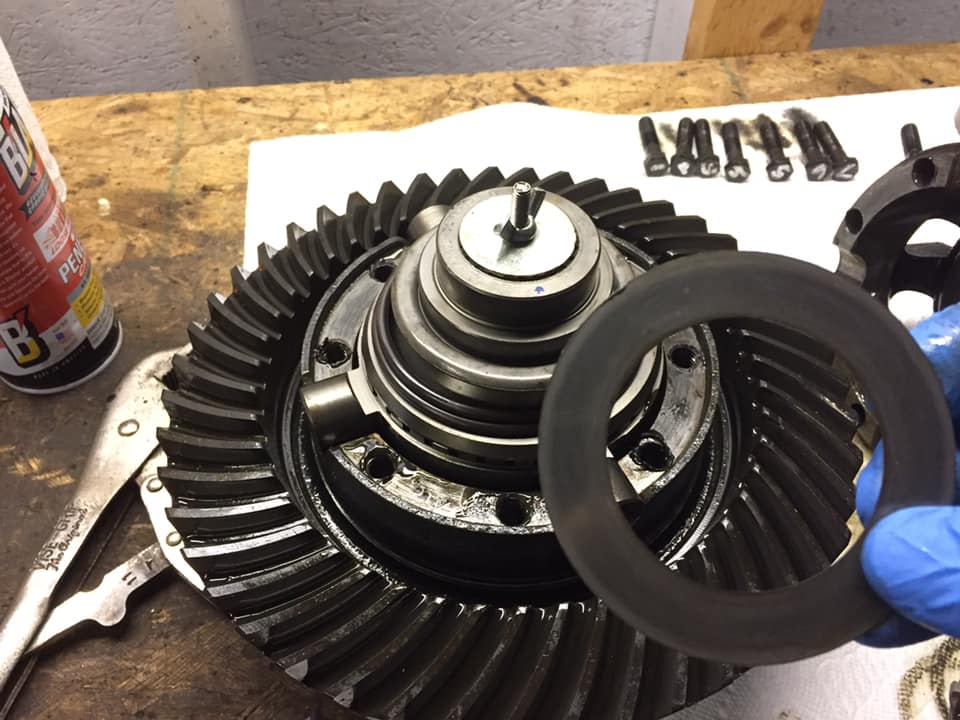

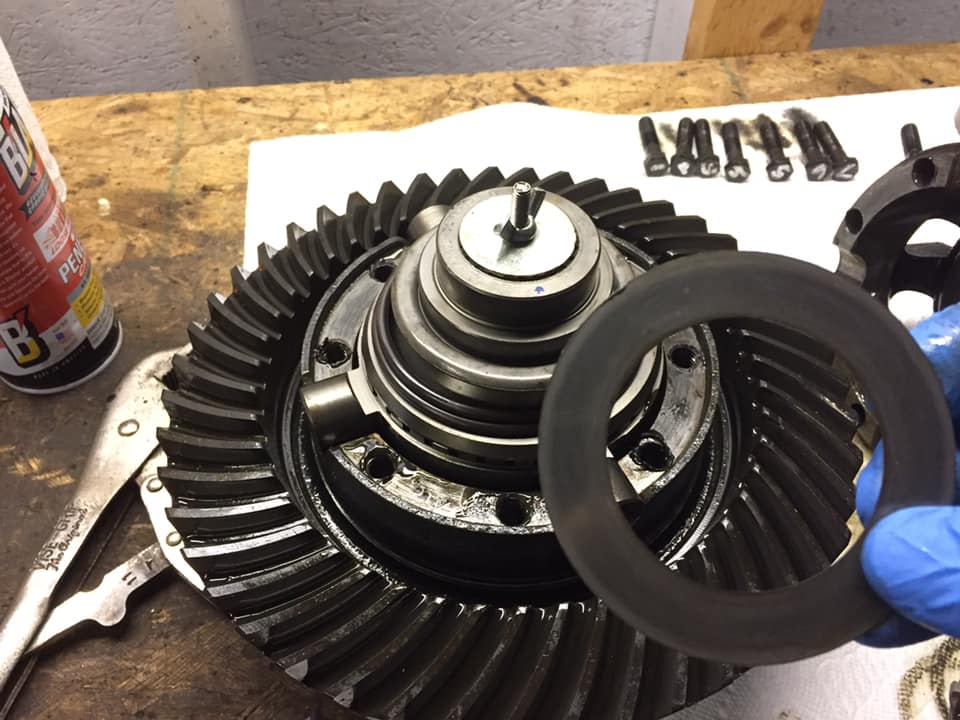

Pulling the diff was easy enough (crowbar and plywood against a ring gear bolt) as was removing the spider gears. I labelled all the bolts from the case just to make sure everything goes back exactly where it came out of.

I initially reused the thrust shims from the back of the spider gears with the locker since they weren't expressly mentioned in the instructions. I decided to call Eaton today and they told me to NOT use those shims. It would cause extremely premature failure. So out they came.

Now the diff is ready to go back in. Just waiting on new carrier bearing bolts.

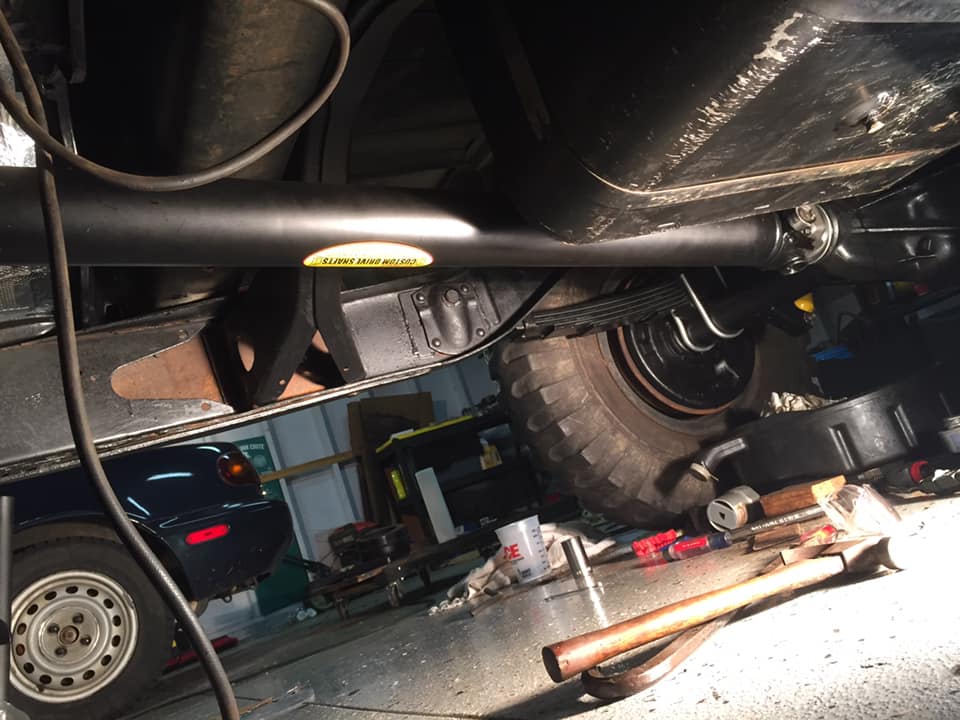

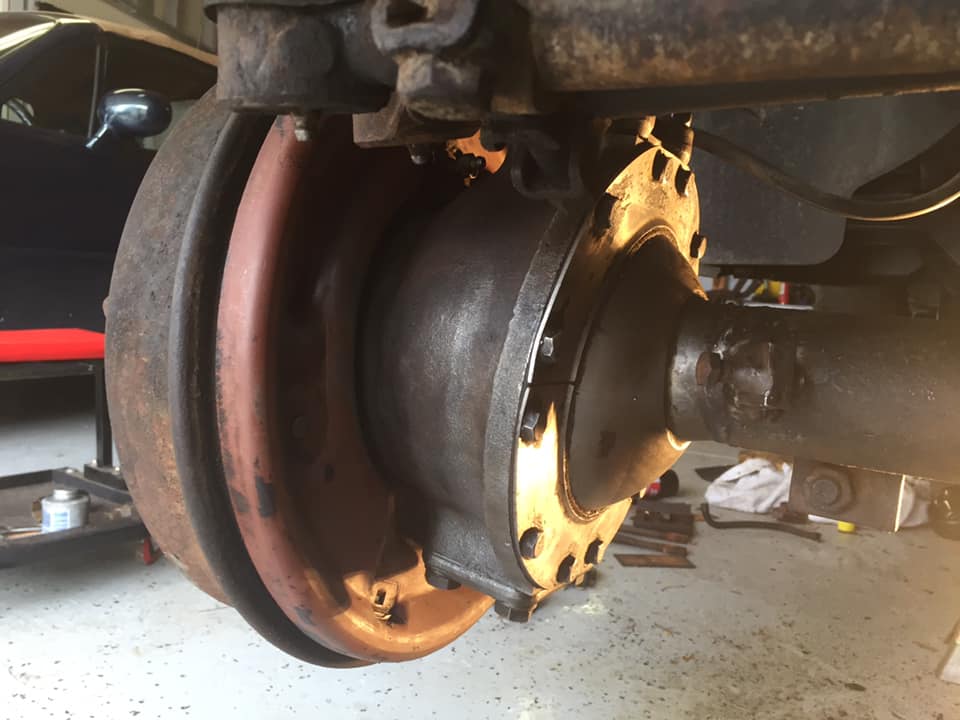

From here, I started to take the axle apart so I can install my Detroit locker and 1410 pinion (thanks to Treepusher's install guide). When removing the hub nuts from the studs, a handful of them pulled out. Oh well.

Other than that, I had just enough room between the truck and the garage wall to remove the shafts.

Pulling the diff was easy enough (crowbar and plywood against a ring gear bolt) as was removing the spider gears. I labelled all the bolts from the case just to make sure everything goes back exactly where it came out of.

I initially reused the thrust shims from the back of the spider gears with the locker since they weren't expressly mentioned in the instructions. I decided to call Eaton today and they told me to NOT use those shims. It would cause extremely premature failure. So out they came.

Now the diff is ready to go back in. Just waiting on new carrier bearing bolts.