J

Jonovision

Guest

2012 Toyota 4Runner SR5 w/ Upgrade Package (Canada)

delivery day, july '12...

and it didn't take long to for things to go sharply downhill from there. As it sits today (Nov/16)...

mods to date...

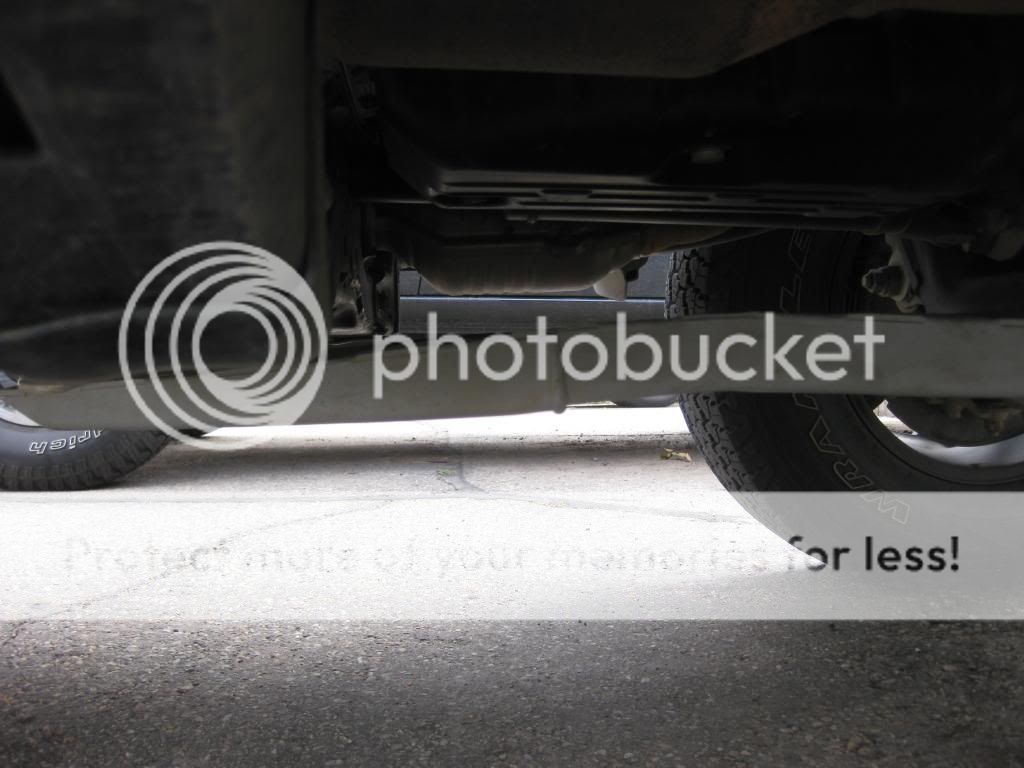

suspension

front

Total Chaos UCA's -poly bushings

Total Chaos LCA's - stock length, dual shock compatible

Total Chaos alignment tab gussets

Radflo extended travel coilover, 2.5” body, Overland Warehouse valving

Eibach 650lb extended travel spring

Offroad Solutions high angle inner CV boot

sway bar delete

rear

MetalTech 4x4 adjustable 4-link, with adjustable panhard bar

MetalTech 4x4 3” bump stop drop bracket

MetalTech 4x4 extended stainless brake lines

Radflo long travel shock, 2.5” body with remote reservoir

MetalTech 4x4 medium progressive rate long travel springs

sway bar delete

armour

(sorry, we spell words funny here....and apologise lots. sorry!)

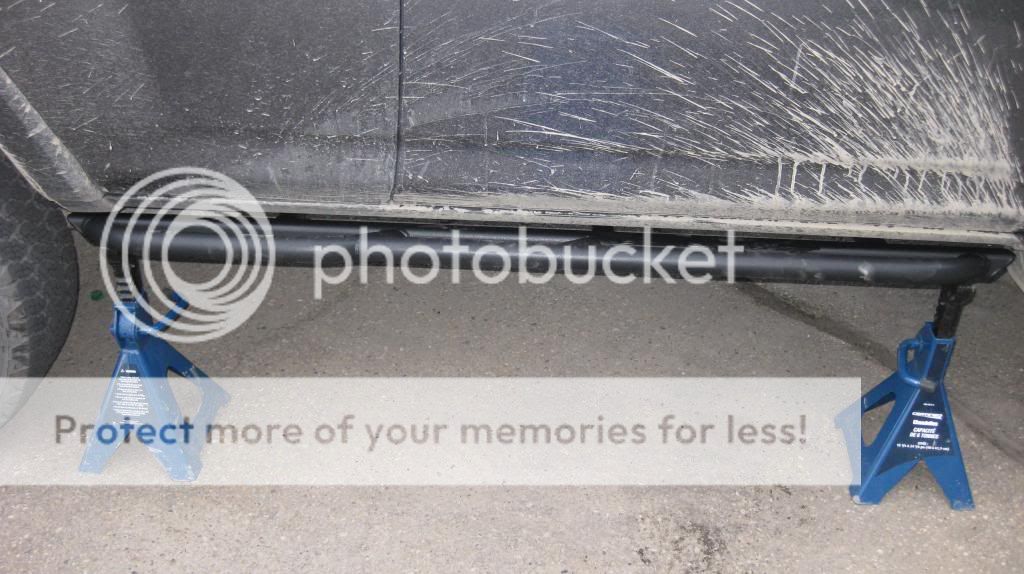

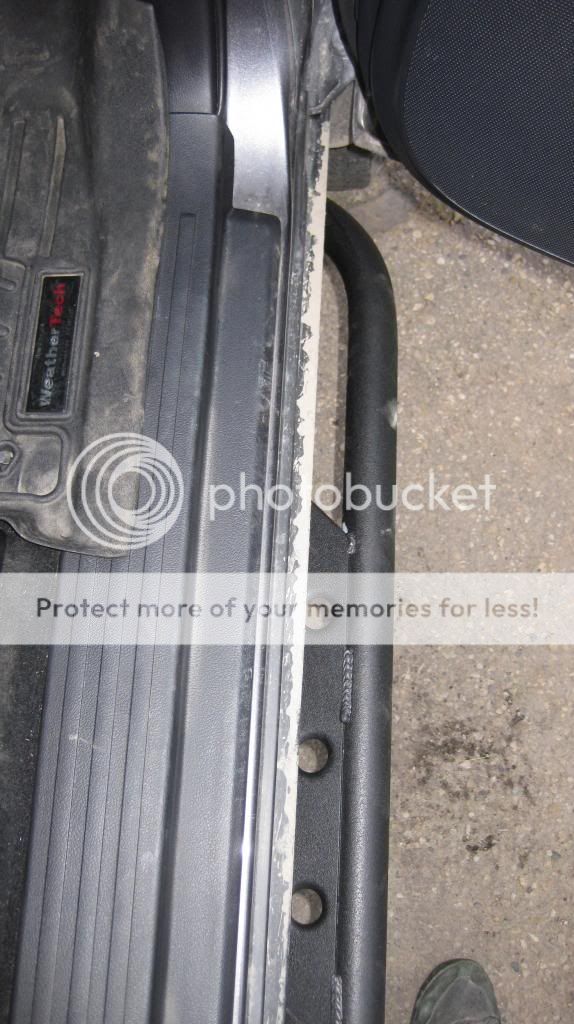

Outpost Offroad Trail Edition sliders

Hefty Fabworks single swing out rear bumper

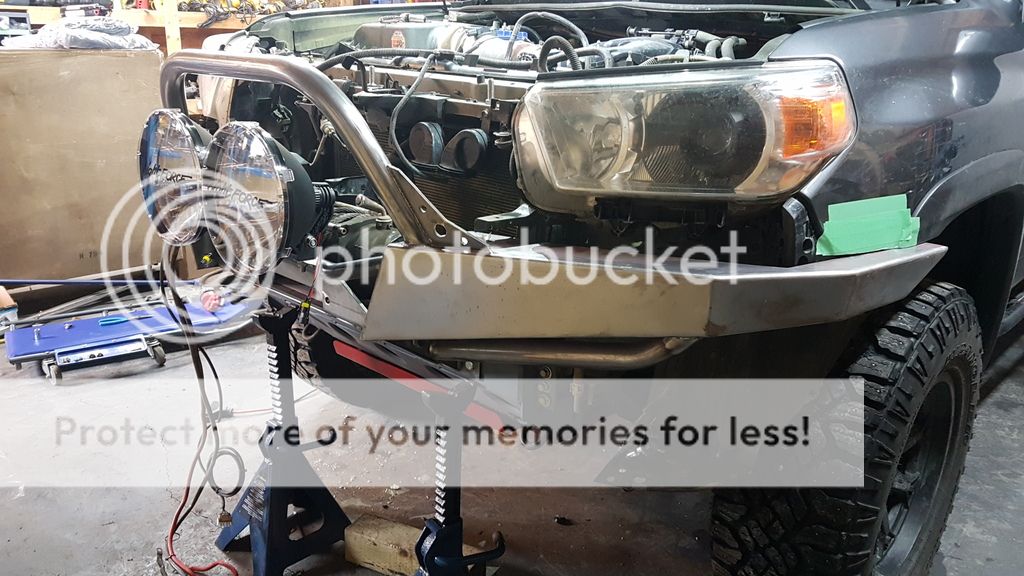

Addicted Offroad front hybrid plate bumper

Hefty Fabworks full steel skid plate package

wheels and tires

FN Wheels Countersteer X 17x8

Ultra Wheels 198 Bolt 17x9

Goodyear Silent Armor LT285/70/17 E range

Goodyear MTR LT285/70/17 D range

Goodyear Duratrac LT285/70/17 D range, studded

offroad and expedition equipment

Camelback Metalgear full length roof rack with additional cross member

Warm VR10000-S

Warn wireless controller

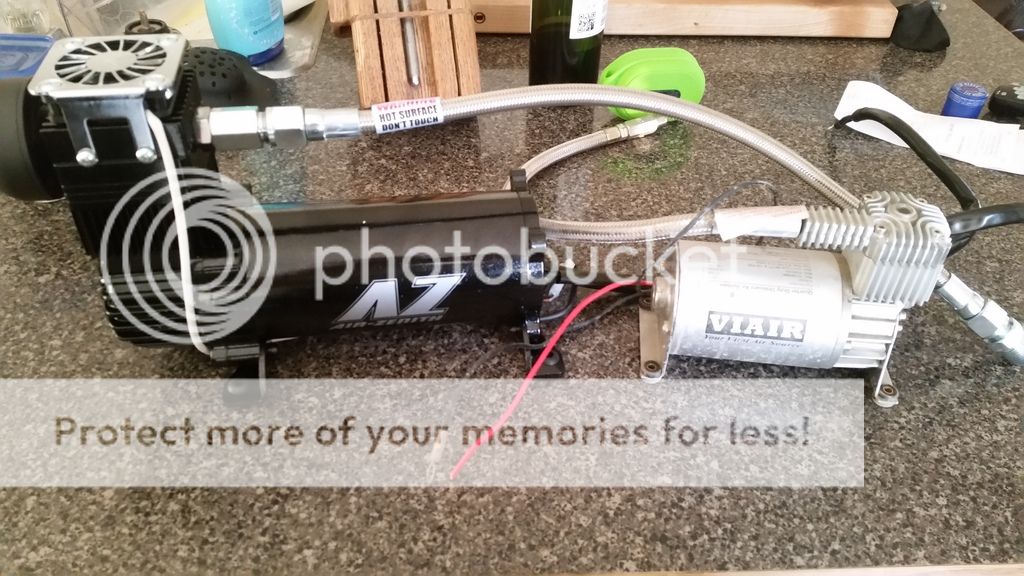

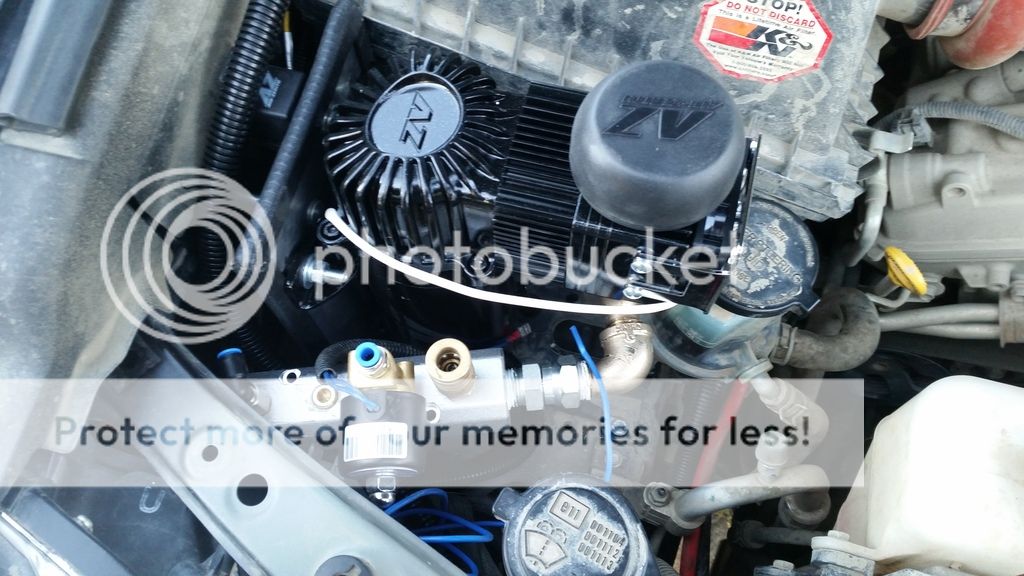

Air Zenith OB2 air compressor

Viair 2 gallon remote tank

Gobi ladder

incorporated rear storage drawers

Wild Coast roof top tent

ARB awning

Axia universal mounts

Koplin chainsaw mount

electricial

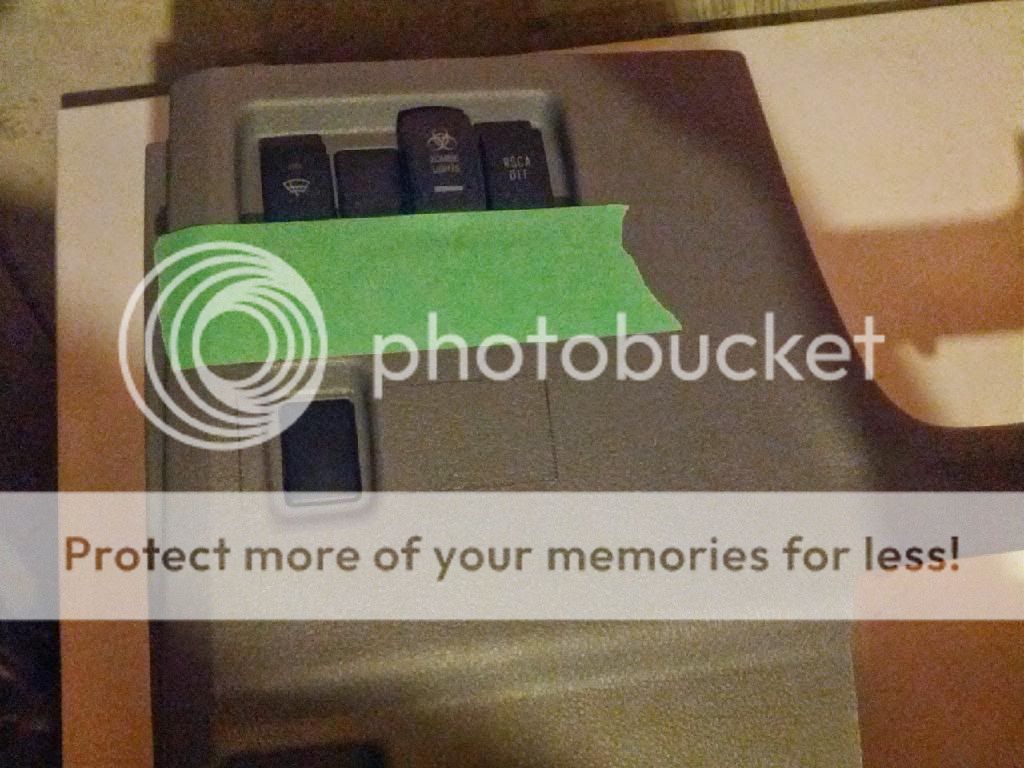

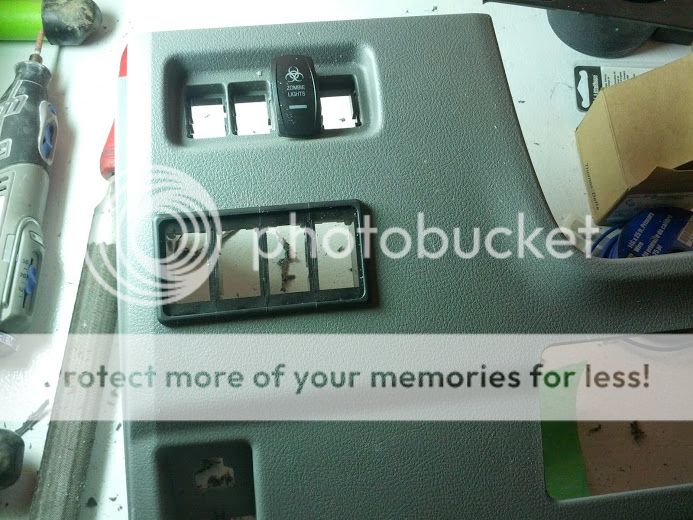

OTRATTW auxiliary switches

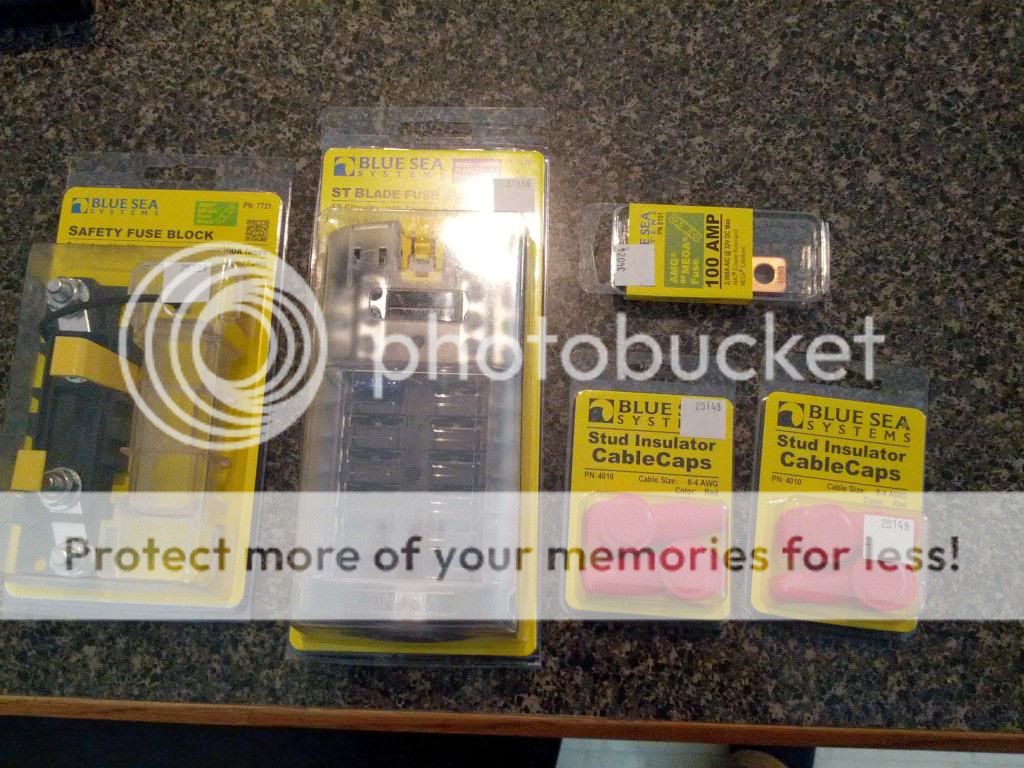

Blue Sea ML-ACR #7622

3x Blue Sea Mega fuse holder #7721 w/ 100 amp MegaFuse

Blue Sea ST blade fuse block #5026

#1 gauge cable, Thomas&Betts crimp on terminal lugs

Pelfrybilt group 31 battery cage

Optima BlueTop D31M house battery

Optima YellowTop D27F starting battery

Stanley 500 watt inverter

2x Raptor LED battery terminals R5BTDMP

lighting

1x Seward Offroad 40” LED bar, combo pattern (forward facing roof top)

2x Rigid Industries D2, flood pattern w/ amber lenses (ditch lights)

CBI Offroad Fab ditch light brackets

2x Rigid Industries A-Series, low power cool white (under hood)

2x Lightforce 240 Blitz, 50 watt HID, yellow spot/combo, crystal blue combo, clear spot lenses (grille)

2x Rigid Industries A-Series, low power, amber (drl/turn indicator)

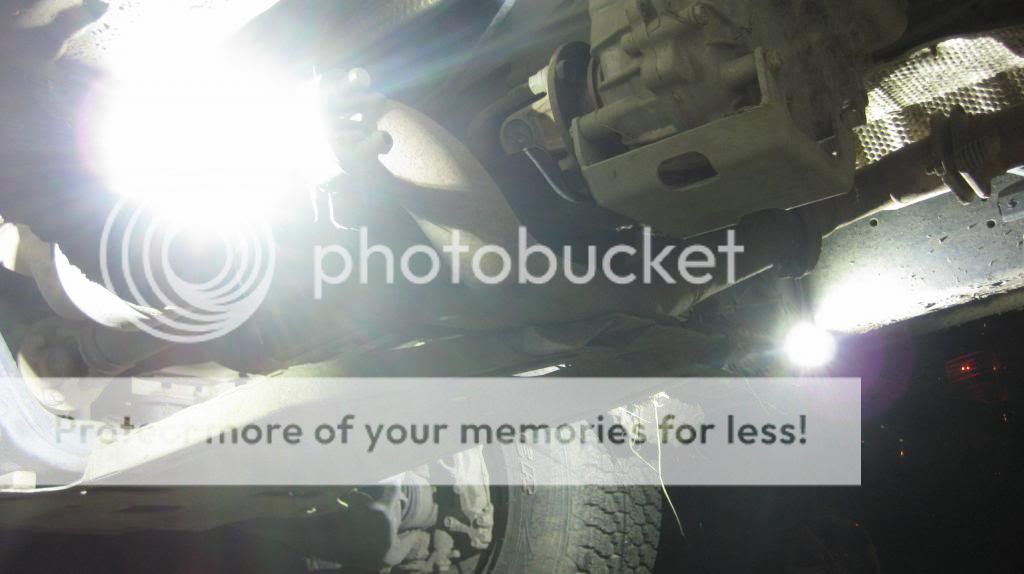

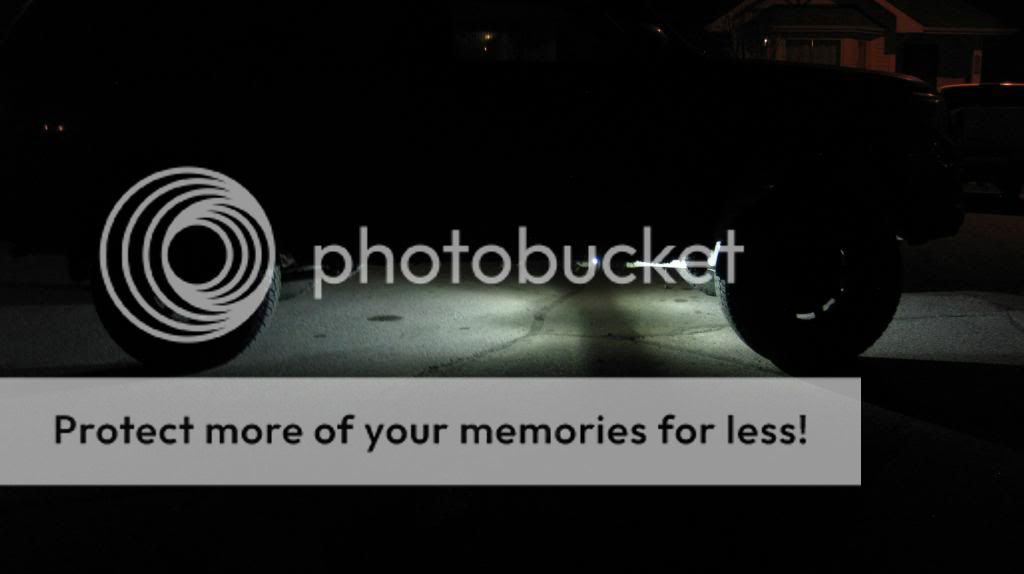

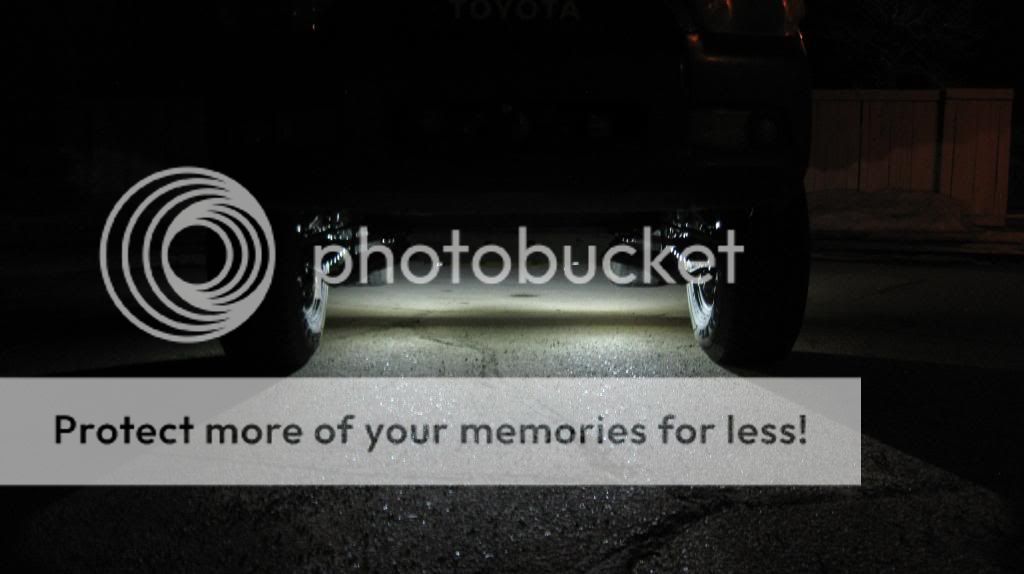

6x Rigid Industries A-Series, high power, cool white (rock lights)

2x Rigid Industries D2 flush mount, fog pattern (fog lights)

Morimoto Mini bixenon projector, “gatling gun” shrouds

Morimoto white 55 watt ballasts

Phillips 55 watt ds2 HID bulbs, 4300k

power

TRD cold air intake

Magnaflow 18” muffler

comms/entertainment

Mangowalk 4” FM antenna

Kenwood DNN990hd

Kicker 12” sub, enclosed box

Concept 600 watt mono amp

Uniden Bearcat 880 cb

u40 4' antenna

Diamond Mount k-540 antenna mount

gone but not forgotten

Bilstein 5100

OME 885 springs

Bilstein 5160

OME 889 springs

ARB skid plates

SuperWinch LP8500 with wireless

Viair 275c

Rigid Industries 20” SR spot pattern

delivery day, july '12...

and it didn't take long to for things to go sharply downhill from there. As it sits today (Nov/16)...

mods to date...

suspension

front

Total Chaos UCA's -poly bushings

Total Chaos LCA's - stock length, dual shock compatible

Total Chaos alignment tab gussets

Radflo extended travel coilover, 2.5” body, Overland Warehouse valving

Eibach 650lb extended travel spring

Offroad Solutions high angle inner CV boot

sway bar delete

rear

MetalTech 4x4 adjustable 4-link, with adjustable panhard bar

MetalTech 4x4 3” bump stop drop bracket

MetalTech 4x4 extended stainless brake lines

Radflo long travel shock, 2.5” body with remote reservoir

MetalTech 4x4 medium progressive rate long travel springs

sway bar delete

armour

(sorry, we spell words funny here....and apologise lots. sorry!)

Outpost Offroad Trail Edition sliders

Hefty Fabworks single swing out rear bumper

Addicted Offroad front hybrid plate bumper

Hefty Fabworks full steel skid plate package

wheels and tires

FN Wheels Countersteer X 17x8

Ultra Wheels 198 Bolt 17x9

Goodyear Silent Armor LT285/70/17 E range

Goodyear MTR LT285/70/17 D range

Goodyear Duratrac LT285/70/17 D range, studded

offroad and expedition equipment

Camelback Metalgear full length roof rack with additional cross member

Warm VR10000-S

Warn wireless controller

Air Zenith OB2 air compressor

Viair 2 gallon remote tank

Gobi ladder

incorporated rear storage drawers

Wild Coast roof top tent

ARB awning

Axia universal mounts

Koplin chainsaw mount

electricial

OTRATTW auxiliary switches

Blue Sea ML-ACR #7622

3x Blue Sea Mega fuse holder #7721 w/ 100 amp MegaFuse

Blue Sea ST blade fuse block #5026

#1 gauge cable, Thomas&Betts crimp on terminal lugs

Pelfrybilt group 31 battery cage

Optima BlueTop D31M house battery

Optima YellowTop D27F starting battery

Stanley 500 watt inverter

2x Raptor LED battery terminals R5BTDMP

lighting

1x Seward Offroad 40” LED bar, combo pattern (forward facing roof top)

2x Rigid Industries D2, flood pattern w/ amber lenses (ditch lights)

CBI Offroad Fab ditch light brackets

2x Rigid Industries A-Series, low power cool white (under hood)

2x Lightforce 240 Blitz, 50 watt HID, yellow spot/combo, crystal blue combo, clear spot lenses (grille)

2x Rigid Industries A-Series, low power, amber (drl/turn indicator)

6x Rigid Industries A-Series, high power, cool white (rock lights)

2x Rigid Industries D2 flush mount, fog pattern (fog lights)

Morimoto Mini bixenon projector, “gatling gun” shrouds

Morimoto white 55 watt ballasts

Phillips 55 watt ds2 HID bulbs, 4300k

power

TRD cold air intake

Magnaflow 18” muffler

comms/entertainment

Mangowalk 4” FM antenna

Kenwood DNN990hd

Kicker 12” sub, enclosed box

Concept 600 watt mono amp

Uniden Bearcat 880 cb

u40 4' antenna

Diamond Mount k-540 antenna mount

gone but not forgotten

Bilstein 5100

OME 885 springs

Bilstein 5160

OME 889 springs

ARB skid plates

SuperWinch LP8500 with wireless

Viair 275c

Rigid Industries 20” SR spot pattern

Last edited by a moderator: