Enthusiast III

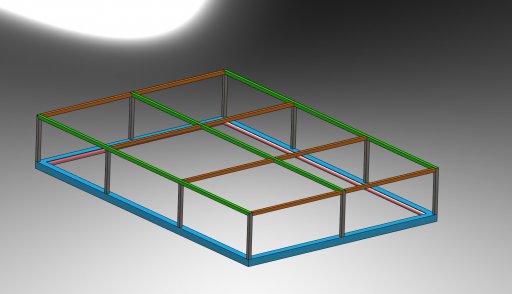

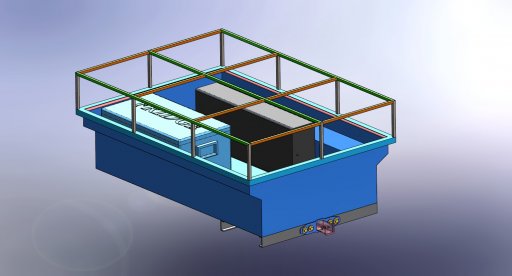

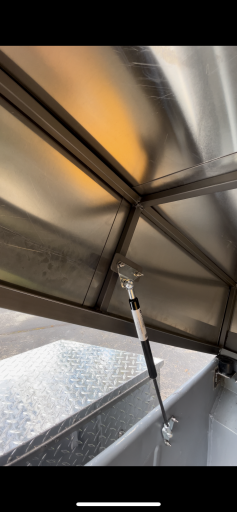

This weeks project was to straighten out the tube rails. As I am going to build a lid for the trailer I wanted a good sealing surface and these were pretty rough. Seems to be only 2 good options...Option 1: replace the rail with new metal such as welding in angle iron to recreate the rail. Con's to that is buying 60 ft of material and lot of welding. Option 2: weld up and grind the damaged areas. Con's to that is lots of grinding. Positive is no money spent...just time. I didn't want to just throw a bunch of body filler on the rail as that would be easiest but I'm sure that would get damaged easily over time after constantly lifting items into and out of the trailer.

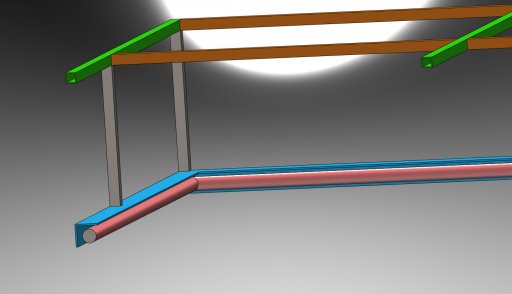

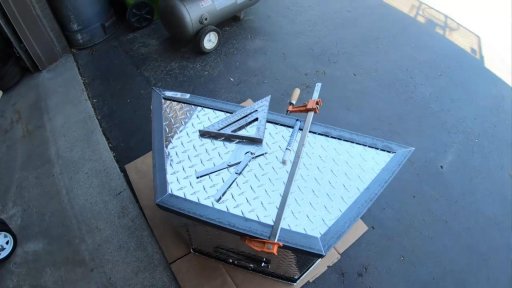

I also wanted to get rid of the step in the corners as that wouldn't seat very well. So i put down a few beads of weld there and grinded them down for a smooth transition.

So I decided I would weld and grind the dents on the tub rail. That was a lot of work but in the end I am glad I did it. It looks so much better and will give me a good surface now. A light coat of all metal filler in a few areas that will mostly get sanded away and it will be good.

I am glad thats over!

I also wanted to get rid of the step in the corners as that wouldn't seat very well. So i put down a few beads of weld there and grinded them down for a smooth transition.

So I decided I would weld and grind the dents on the tub rail. That was a lot of work but in the end I am glad I did it. It looks so much better and will give me a good surface now. A light coat of all metal filler in a few areas that will mostly get sanded away and it will be good.

I am glad thats over!

Attachments

-

84.3 KB Views: 28

-

172.5 KB Views: 27

-

149.5 KB Views: 28

-

390 KB Views: 26