Pathfinder I

Totally agree, that’s a very useful post. Thanks!I think you hit the nail on the head. With now so many different renditions of similar or exact copies, the only variable seems to be the material they are being made from. This is why I went with a X-BULL copy by ORCISH. It used virgin plastic/nylon vs recycled plastic /nylon. Seemed to get better reviews and was touted by ORCISH as of course being a better product. Time and use will be where the rubber hits the road on these, but the price was too good to pass up,, considering the retail price variations of all these boards on the market.

At one time I had considered the Smitty's, but as you mentioned, they were getting horrible reviews and I have not seen or heard of any improvements in their durability. And I might add, the price has creep-ed up, as has many recovery boards on the market. MY OPINION: If any company decides to release a version with the MAX-TRAX durability reputation, while keeping it at the $100.00 mark, they will corner the market.

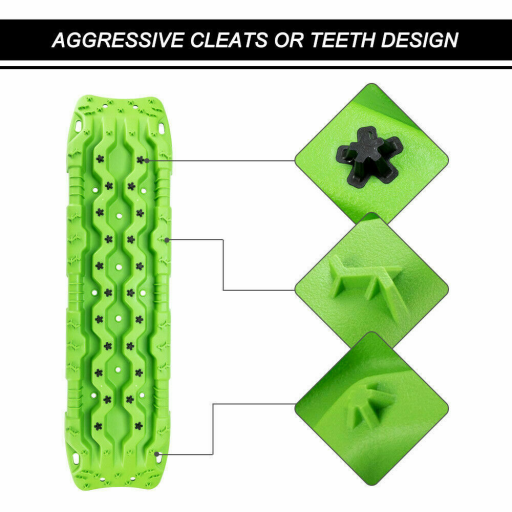

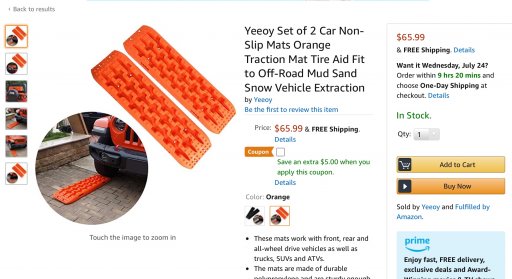

EDIT: picture of the ones I got in olive greenView attachment 106811Came with a bag & tethers. Amazon=$98.99, E-Bay=$69.90 right now!