Member III

I'm building the front ones. I'll see how they turn out. I changed my frame design and forgot to work in the front jacks. I need something narrower than the Bal jack.

Member III

Member III

Member III

8300

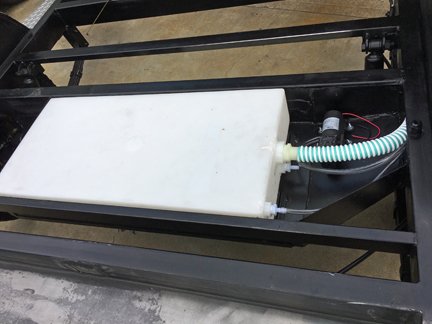

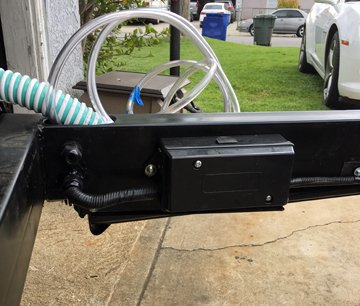

I figure that when I got the frame all done, I was 10% complete. Good Luck.Didn't get much done this last weekend. Had family visiting. Well that and it rained. Was able to make a run to the steel yard, got my box made for the water tank, got my external junction box mounted and added in the mounts for the tongue box. Ran out of paint and forgot to order a few items.....sigh. Oh....didn't take any pictures.

On the plus side, the frame "should" be done this weekend. I think I'm going to throw some wood on it and do the registration before I make the box. I haven't ordered the doors and windows yet. I'm guessing there's going to be a bit of lead time there.

Major items left to order (beside doors and windows), fridge and kitchen slides, aluminum for the walls and roof, misc small doors for shore power, water fill.....ect.

Member III

Member III

Member III

Influencer II

Expedition Master I

24954

Member III

Member III

Member III

Member III

Member III

Traveler II

Member III

8300

Member III

Drawing it out doesn't cut it for me. The concept picture is almost scaled correctly and I still didn't know how it would be when it was done.Being a fabricator and engineer, I love your blue tape mockup. Sure helps to visualize it.