i've spent most of this thread talking about how i want to keep from making holes in the trailer, especially in the roof, but i had to run my solar cables and ended up punching the first hole, which of course is in the roof....

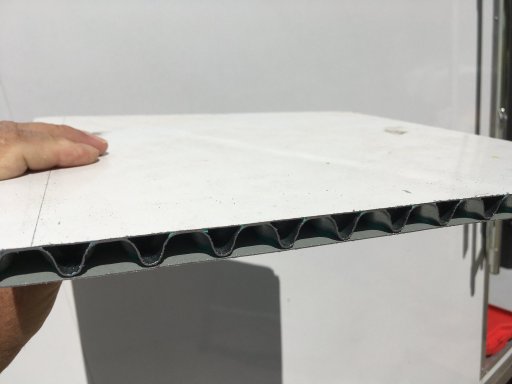

most cargo trailers are built with 1" square tubing ribs with extremely thin sheet metal panels for walls and roof. these are difficult to seal well, especially the roof, because the metal is extremely thin and flexes a lot and most of these type trailers have a convex roof, so the bigger the hole, the harder it is to have a flat area to work with. anyway, i went with a new trailer that has aluminum composite panels and no framing members. it even has a flat roof.

these new panels are great. i got on the roof and popped a 3/4" hole and there was zero flex. very nice.

i ran the 10awg cables thru the hole and then sealed the hole with a polyurethane flashing sealant. (i used that because its a good product and i already had a tube open)

i then applied the same sealant to the bottom of a gland box and stuck it to the roof...

i then went around the box with Uniflex seal tape. when i had my construction company, we did a lot of sealing on commercial metal roofs and this seal tape has worked extremely well for the past 15 years. it is a very sticky tape that has a cloth back that readily accepts sealant coatings, like Dicor and Flex Seal. there are roof sealant tapes out there that are really good and have a membrane already built in to the tape. these are good and last a long time, but i prefer to use this type of tape and then apply my coating after i have the tape applied and all air bubbles removed.

next, applied a polyurethane seal coat and after that cures, i'll go around it with Dicor self-leveling sealant for a nice smooth finish

i dont mess with products like Flex Seal or really any product found in home depot or lowes. some of the products are pretty good, but since i did commercial construction, i just stay with the better products. sherwin williams has the Uniflex tape and also a Uniflex liquid sealant. most of the good commercial sealants come in a 5 gal bucket, so they are usually a no-go for most folk who only need a quart at best. that is when i go with products from Dicor and Sika, which have commercial grade products in smaller quantities.

after seeing how rigid these panels are and how there are no framing members to worry about, i might just go ahead and pop a hole big enough for a Mr Fantastic roof vent fan or just install a Dometic ac unit since the cut out is the same size. i'm even ready to cut out for a window now!

i guess its like babying a new truck and then after you get that first scratch, it doesnt matter anymore. after popping that first hole, i feel the same way now