Advocate III

- 5,584

- First Name

- Michael

- Last Name

- Rose

- Member #

-

20990

- Ham/GMRS Callsign

- W7FSB

- Service Branch

- US ARMY Retired

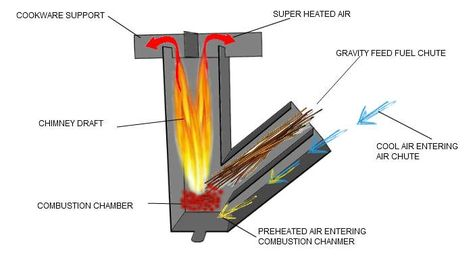

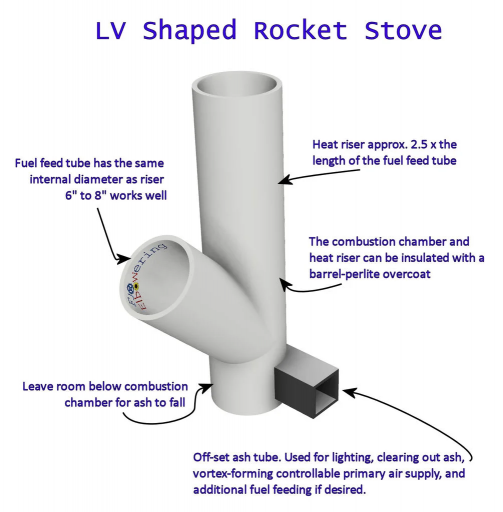

My son wants to build a Rocket Stove out of square tubing for a high school project. I dont have any idea of what size tubing he is going to need or how long of a stick I need to order. We want to design this thing to be compact enough to stow in the back of my Bronco, but yet big enough to fit my griddle on it.

Im prety good at designing things when I understand the science and the ratios, but im not finding a lot on google or just not using the right terminology.

Im prety good at designing things when I understand the science and the ratios, but im not finding a lot on google or just not using the right terminology.