I was reading through this thread in the spring, but just muscled the tent up on top with help from the father in law. But, since I almost killed him (the new hardshell is close to 200lbs), I had to come up with something mechanically advantageous for in the fall.

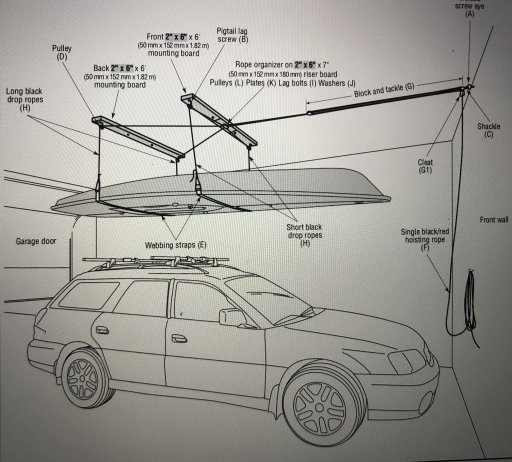

I wanted to use a hoist, and my alley slope + garage peak was high enough to do the trick.

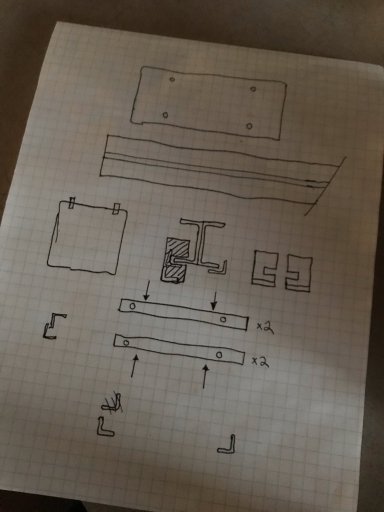

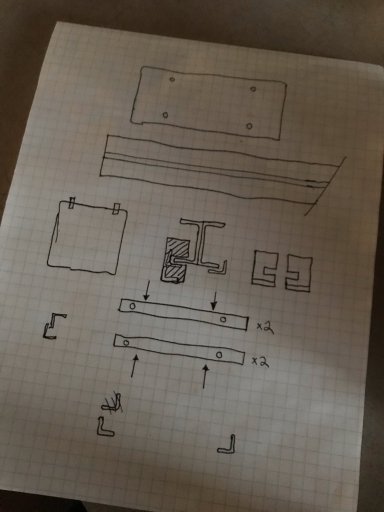

I have several unused network racks, that come with 2x 90'ish" 1/4' aluminum c-channel, and some even thicker angle plates. These are going to become a powder coating oven frame, but I used three up for the hoist main beam, and load spreader.

the hoist is the cheapest Princess Auto / Harbour Freight chinese special 200/400lb winch.

I used the pulley block, and doubled it, to just slow down the movement.

I didn't have enough webbing to make the spreader slings I wanted today, but I will for next spring.

I make a couple pieces out of angle steel, welded and powdercoated them myself. The interface for the hoist to beam, and the saddle for the beam. When I went to use my sandblast cabinet for the powder, I had to take it apart and repair, and made a new bottom feed metering valve in the process. (would have bought a already made one, but they are sold out everywhere).

All in cost was really just the hoist, as all the aluminum was free. The angle steel I had already. I put in about eight hours, and lots was tinkering, and overbuilding.

Happy with the result. And, no one died!