Wow... AWESOME thread for us WJ folks. I just gave it a skim from the very first post through the end; lots of good info and I appreciate the opportunity to learn from your experiences. Three things right off the bat that you've done which I'm interested in and might repeat are:

- 180 T-Stat

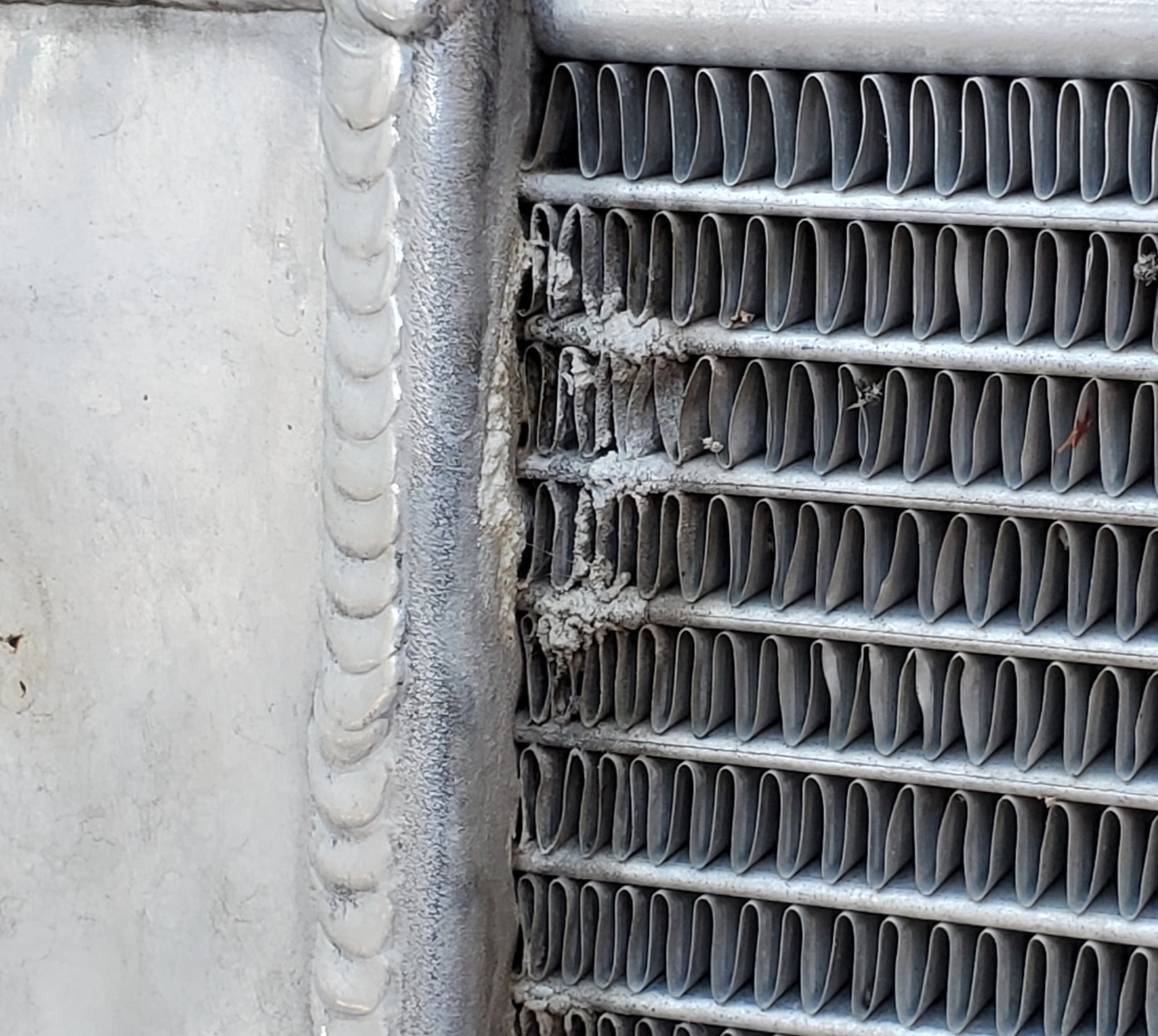

- All-AL, larger rad

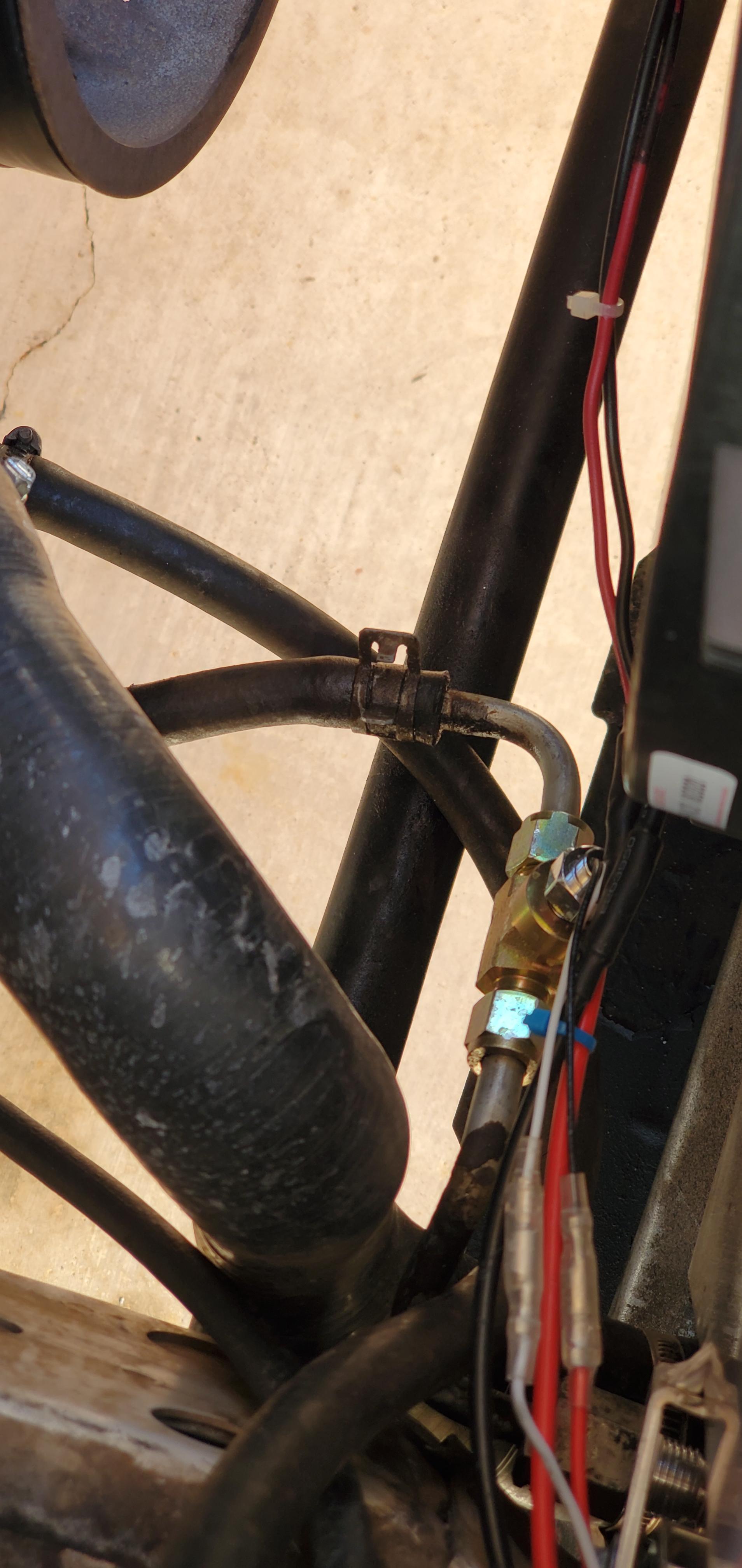

- Oil Cooler

Now, you might read that to mean "TJ has overheating issues with his WJ." But in fact it's much the opposite. I've had ZERO problems with overheating, but I like to be proactive, and as you pointed out the 4.7 does not do great IF you do overheat it. I'll probably start with a T-stat and rad sometime soon, and if I feel it make sense I'll add the oil cooler later.

I'm also interested in your tow hooks, did they come stock on your Laredo? My Overland doesn't have any.

Also, a little bit of input, and a few observations:

I'd love more info on the 4-hole injectors, but I have a HO so my flow-rate and part number are different. We all know the 4.7 doesn't have the smoothest of idles, but a fresh set of 4-holes with the increased atomization might help. From what I've found the 4.7 HO could be 2 or 4 hole stock, so it might not be an "upgrade" if I had 4-holes before, but a fresh, clean, balanced set is never a bad thing. Anyway, what I actually meant to comment about here was the look of that plug. There's no nice way to say it, but I don't like the look of it. I wrote a little something about spark-plug-reading here:

Spark Plug Reading... - Dune and Dirt You may want to give it a skim. I imagine the issues with your plugs had a lot to do with the bad injectors, PCM, wiring and sensor issues you were sorting out.

Still, I'd go ahead and pull your plugs and inspect them now. Everything should be tip-top and your performance and MPG seem to support that, but I'd want to see what the plugs look like now. As talked about in that thread, to get a good read you want to try to get the plugs out after some hard pulls with as little idling around after as possible. This is often really hard to achieve, but you can get close by doing some hard pulls, pulling directly in the garage and shutting it off. With race-stuff we do a WOT pull and actually kill the ignition, coast to a stop, then tow it back to pull plugs.

Please keep in mind I'm only trying to help, not be "that guy", but you're misunderstanding multi-grade engine oil. Basically, when you see two weights listed on an oil (like 10 and 30 in "10W-30") the first weight is the viscocity when COLD, the second is the HOT viscocity. The lower the number, the less viscocity (aka "thinner") the oil is. So, the difference between a 10W-30 and the 5W-30 you switched from is only experienced when the oil is relatively cold, at which point it is indeed thicker. However, when the oil is hot, where you said you were experiencing a breakdown in lubricity both oils are of a 30 viscocity, and would perform the same. That said, lubricity and viscocity are not the same property, and a lot of lubricity has to do with the quality, condition and age (age more in heat-cycles than time) of the oil, as well as the additive packages. Not all 10W-30 oils will have the same lubricity at 240 degrees F, however by SAE standards they

should have the same viscocity.

The moral of the story is, if you feel you have insufficient viscocity at high temps (which is roughly analogous to lower oil pressure at high temps) you want to move to something with a higher number in the 2nd position (like a 15W-50... though you would want to note it's also thicker when cold, so if you live in a very cold climate it might not be a good choice). If you think you have actual lubricity issues (as witnessed by doing oil-sample-analysis and finding higher traces of bearing materials and such) you want to go to a higher

quality oil. Finally, I'll note that there is definietely such a thing as "too thick" of an oil and "too much" oil pressure. It's often assumed that more oil pressure is always better, but that's just not the case. The factory bearing clearances were set with a particular range of oil pressures in mind, changing oil pressure (via oil weights) outside of the factory specs can cause far more harm than good. You really only want to go up in oil viscocity when your pressures have fallen outside of the acceptable stock range, but you should be aware at that point it's just a bandaid for a worn motor.

You can sign up on their site for a small fee, which allows you to order direct at a discount which usually more than covers the fee.

Anyway, again not trying to be preachy, just trying to help. Here's my WJ thread if your're interested, though it's not nearly as detailed... yet:

2003 Jeep Grand Cherokee Overland Build

-TJ