Enthusiast III

Hi everyone! I'll be posting my build log here. I have posted bits of it else where, but consolidating and archiving it would be great! The first couple of posts will have my archived items.

=====================================

I bought a used 05 Sequoia almost 2 years ago now; in May 2019, and after having worked it for so long, I've decided to make a build log on it.

This is my first vehicle that I have ever personally worked on, and my first time experiencing offroad type builds. If anything, this is an Adventure Vehicle. A lot of the trips I plan to go on will be slightly off-grid, but nothing towards the expedition level where I'd travel 50+ miles just off road/ off grid....for the time being.

Hope ya'll enjoy it as I try and find / create information for everyone to use! I'll try and document it as well as I can. A lot of these projects have been inspired by mods that are available for other platforms, and mods others have done on the TSOR Facebook group page.

Lastly, I'll put some thoughts on the decisions I've made, and why I went that way. A lot of the decisions was made for a functional purpose, for when and if I needed it. Some of it,

INITIAL PURCHASE DECISION MAKING.

I purchased this vehicle Mid 2019 with the intention of making it a vehicle for road trips / camping. At this time, I was only interested in using it as a family hauler, as my family had sold the minivan around 2010, so we only had sedans. In those 9 years, we went on less road trips and it's something that I wish I had more in my life, even if it was only a handful of times a year.

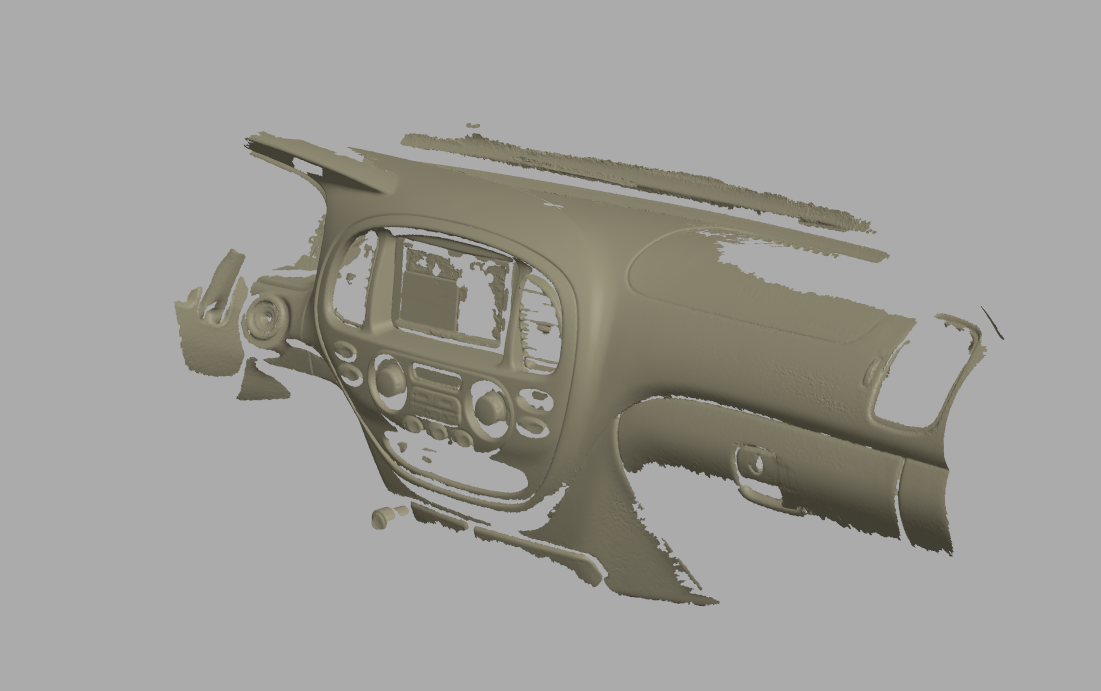

Initially, I was looking at a 3 row 4runner with v8, but learned that it was a very rare spec, and the trunk space was basically non-existent. After looking around for a few weeks, I found this 05 Limited Sequoia, and jumped on it. After initial inspection, it appeared to be in good condition and the main parts of it were in working order, including the ENGINE, 4X4, TRANNY, AC, FRAME, SOUND (aftermarket with backup camera & android/apple car play), and all of the buttons, except the rear window. All the initial inspection learning was done from Youtube via Chrisfix, and any other Sequoia focused videos.

The Good

1. Frame condition is good

2. Aftermarket headunit, sound system, and backup camera.

3. Engine had good compression

4. 4HI/LO + Center diff activated.

The Bad

1. Missing fender molding (Driver side).

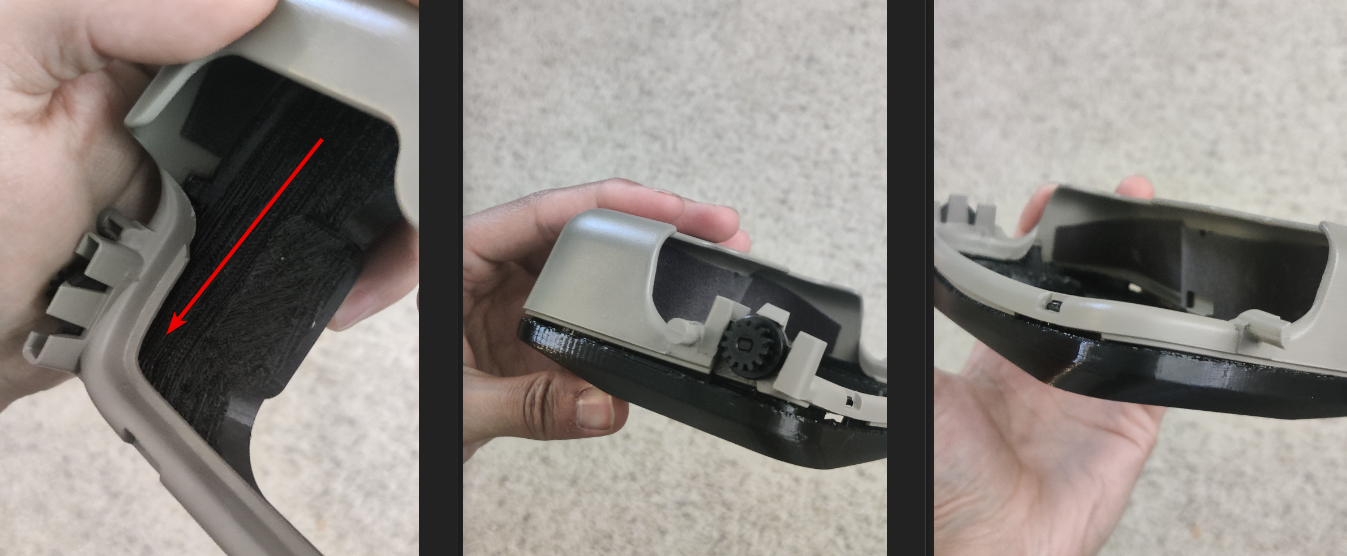

2. Liftgate did not work, but also sensor and trunk light didn't work (later I learned that it was missing a computer unit, and the trunk was the main issues with this vehicle in terms of electrical work)

3. AC dial rarely registers

4. Liftgate lights did not work

5. Driver / Passenger seat was starting to rip.

May 2019, after purchase.

View attachment 2602635

May 2019, two days after purchase.

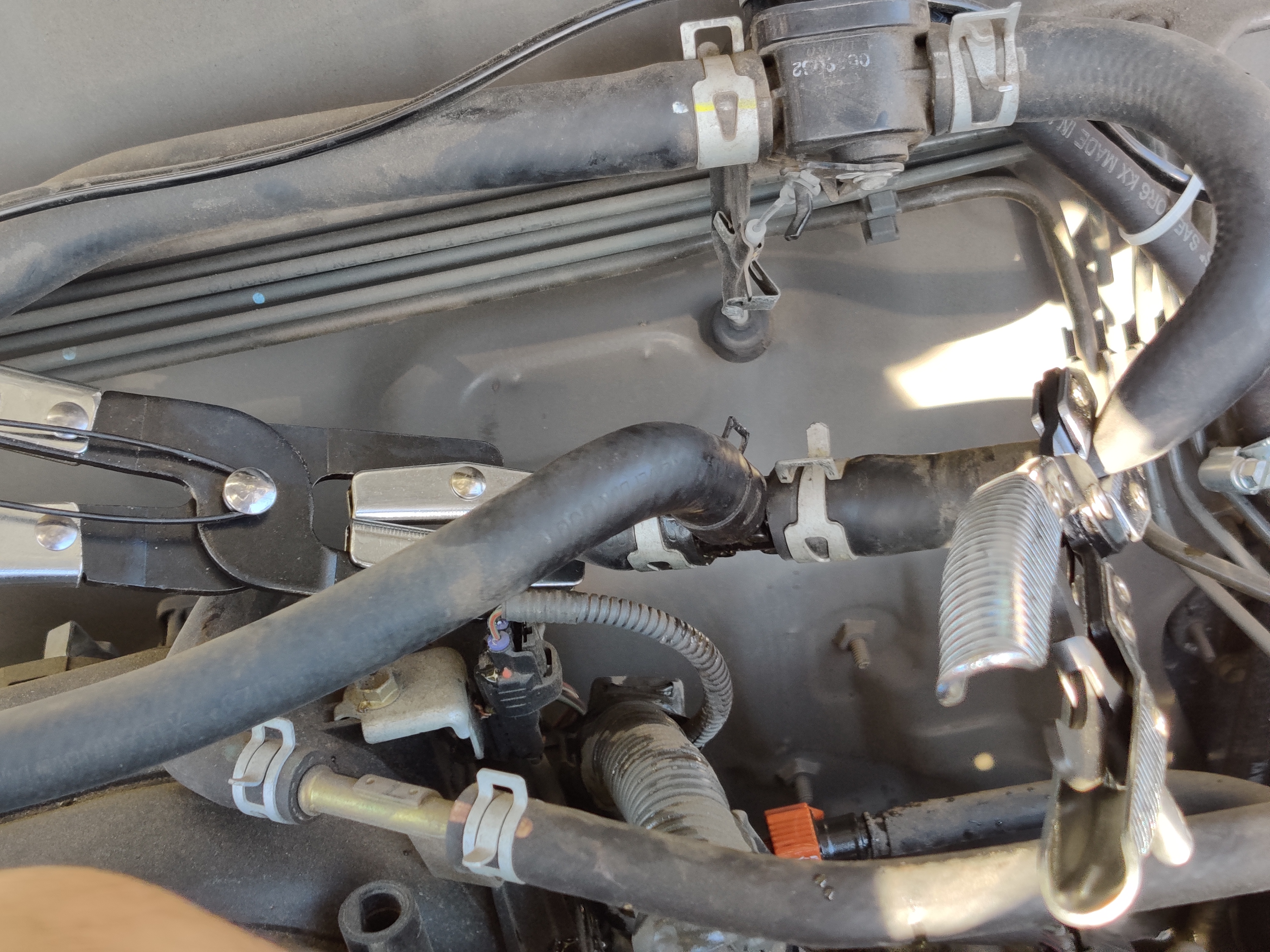

Initial researched informed me that if the timing belt snaps, the whole engine is toast. My first maintenance jobs on this was to change the timing belt, water pump, pulleys, oils, including diff / transfer case. This was my first time doing this difficulty of job. My only previous experience was changing brakes, a starter in a CRV, and oil change. It was very challenging and it took me 3 days to do as I was missing some tools to brake some bolts. I also did some other jobs that were done on the way to this job.

Good References on Timing Belt DIY

The OEM Repair Manual.

Products used:

Aisin Kit

Mobil1 Synthetic Oil

Redline Gear Oil

Toyota Pink Coolant

Jobs Performed

Brake Fluid Flush

Dash Cam Install

Coolant Flush + Cap Replacement

Serpentine Belt

Timing Belt

Water Pump

Front Diff Fluid Drain + Fill

Rear Diff Fluid Drain + Fill

Transfercase Fluid Drain + Fill

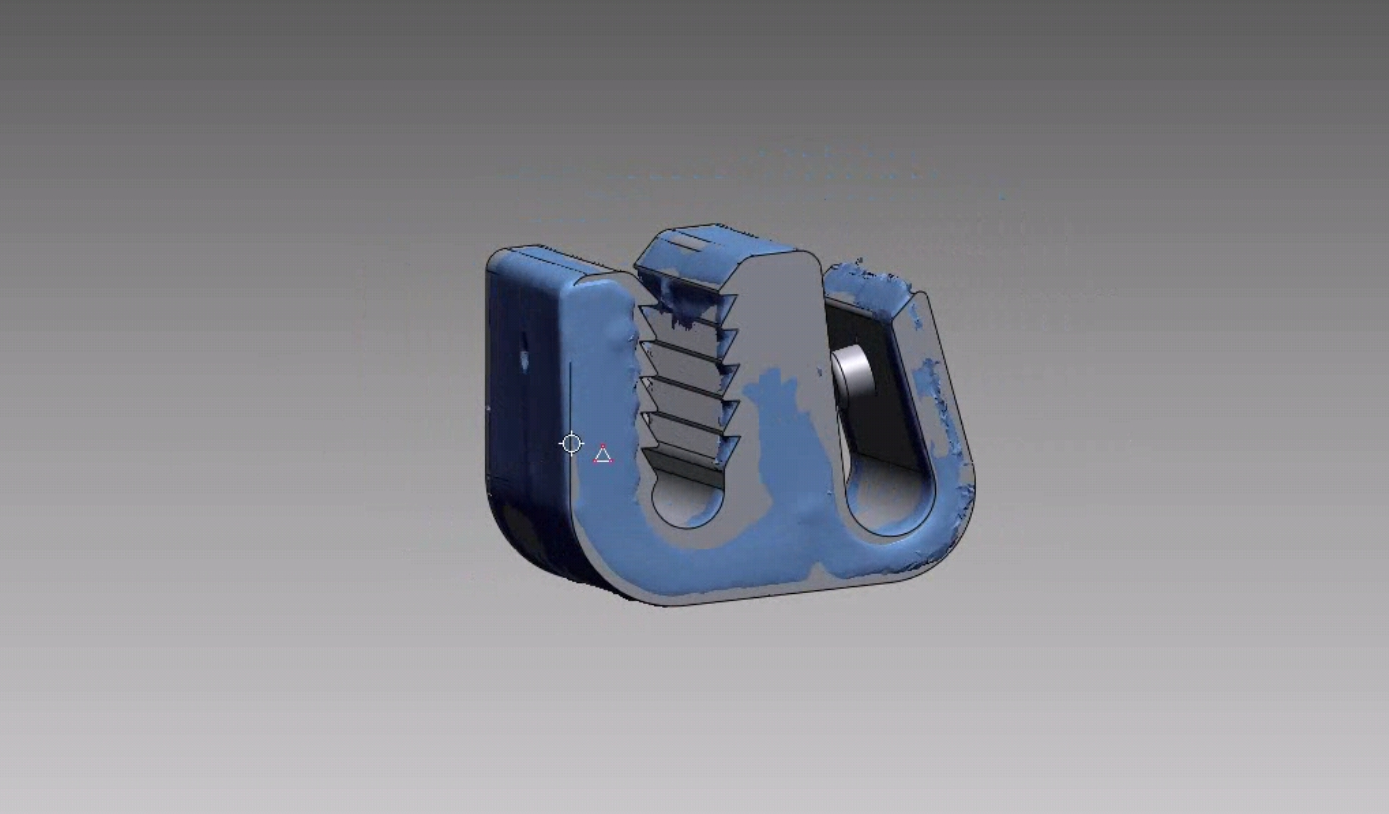

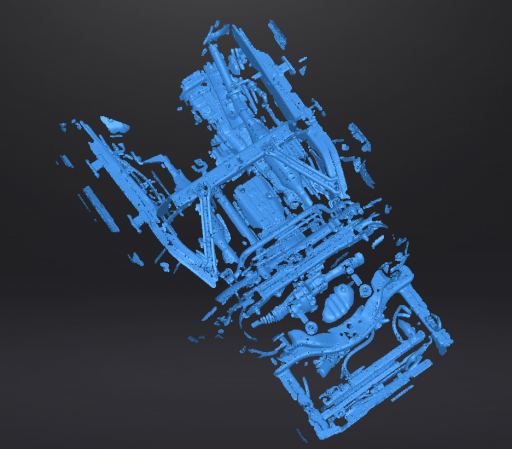

View attachment 2602636 View attachment 2602637

Late May 2019, I took it to Zion to camp with friends.

It was a great time and my first time driving on non-pavement. I've never been "off road" or really on any forest roads. It was a bumpy ride, and I didn't know the concept of airing down. I thought "if has 4WD = CAN OFF ROAD".

This was also the first trip that I didn't book a site for. It was all informal, and was a dispersed site in the Forest. Loved the freedom to move sites as it was windy / raining the 2nd night.

At this time, the Sequoia is still stock, but I've been lurking the TSOR page a lot and seeing where I could go with this.

View attachment 2602647

Late June 2019

I had a misfire in cyl #8. After inspecting the coil, it had a partial crack in it. Decided to go on a budget, and went to the junkyard for a few coils. Replaced the coil in cyl 8, and also bought new spark plugs.

Used Parts

NGK Sparkplug - IFR6A11 or you can go with the Denso Sparkplug - SK20R11 // Both are recommended in the manual, but I went with NGK.

- Electrode gap: 1.0 to 1.1 mm (0.039 to 0.043 in.)

Coil Pack - #90919-02259

I decided to clean the carpet in the Sequoia. Was nasty A F.

View attachment 2602656

August 2019

Took my family to Sequoia National. Was awesome! We did encounter a bear, so that was a tad scary.

Early August 2019

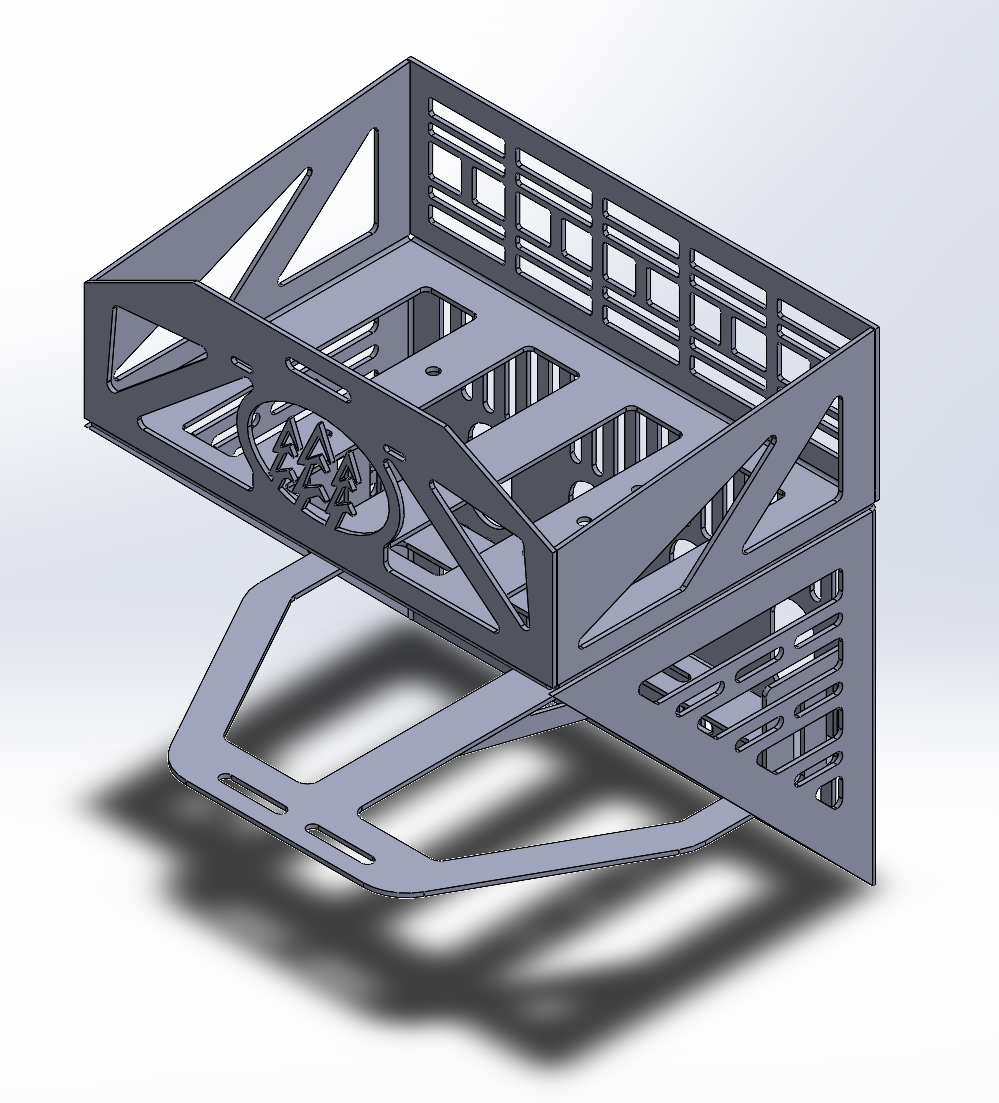

One of the biggest concerns about bringing more than 5 people on a trip was storage. On one hand, you don't need too much gear, if you need to abandon the vehicle, but you still need some essentials. The current consideration is not "expedition" type trips where I need a get home bag. Most of the places I'd travel to will likely have others around and will be somewhat popular / destination spots. I'd want to go to places where there are less crowds, where there are some physical limitations to where you can go. I'm not very into rock crawling and I just want a vehicle that I can depend on to get to places and back.

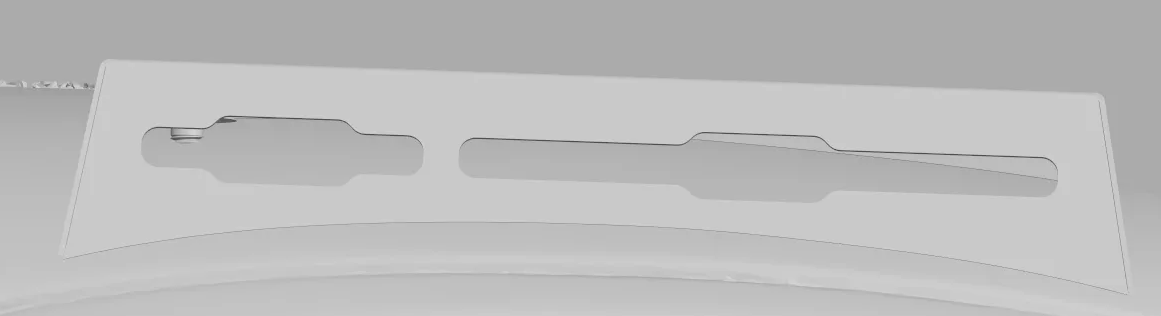

The Thule skybox was purchased used for $200, and is one of the larger ones. I also have a plano box I had, but in order to have it in the vehicle, I had to remove a chair in the 3rd row, which reduces 2 seats. I have to make some considerations on how to use part of the roof, but also maximize the rear cargo area. I don't think I need to have a lot of gear, but having to dig through it was quite cumbersome. At this point in time, I also discovered that people had drawer systems in their rigs. This would be a gamechanger, but I don't really have much experiencing wood working. On top of that, wood is very heavy, but going with aluminum is expensive, but has a good strength:weight ratio.

Mid August 2019

On my first trip, I had a big cooler attached to the rear hitch of the the Sequoia. I didn't know much about exhaust heat, and the exhaust was pointed directly at my cooler. It melted part of it so I decided to angle the exhaust. I went to a random muffler shop I found, and they did this for $20.

Thoughts in 2021, as I write this: regret doing this, and wish I had went a different direction. I think today I'd consider cutting the muffler, and then angling the piping so it aims down or to the side. Unsure how this would be achieved, but it's something I'd consider.

Sept-Oct 2019

At this point, I decided that I wanted to install ATW3's 33s (285 70 17) onto my Sequoia. I wanted it to be capable of going up roads with confidence, and also going snowboarding without the need of tire chains most of the time. We go snowboarding multiple times during the winter and chains were required at times. Safety was a huge factor in going towards this route as in my previous SUV (AWD 06 CRV), I slid on ice roads in Mammoth thinking "AWD = TRACTION". I also wanted to experience something new, learn more about working on cars, & have the ability to take on new challenges with the Sequoia.

I decided to go with a modes and economical lift kit, and also change the LBJs after reading the horrors of its failure.

Thoughts in 2021: I wish I went with something better for the front such as OME or DOBINSONS.

Parts Used

FRONT SUSPENSION

Bilstein 5100s on Bottom Notch with OME 2885 in the FRONT.

- Also had to use Energy Suspension Coil Isolator to seat the new coil for the front.

TOYOTA OEM LBJS.

SPIDERTRAX 1.25" WHEEL SPACERS.

REAR SUSPENSION

OME 60024L with OME 2865 in the REAR

- Purchased additional washers at Home Depot for the shock mount.

FREEDOM OFF ROAD UCA

- Fair price. Their CS is pretty good at responding, but I wish their information was more complete. The nut they use is non-standard and can't even be purchased at McCasterCarr.

- Part is IMPORTED.

=====================================

I bought a used 05 Sequoia almost 2 years ago now; in May 2019, and after having worked it for so long, I've decided to make a build log on it.

This is my first vehicle that I have ever personally worked on, and my first time experiencing offroad type builds. If anything, this is an Adventure Vehicle. A lot of the trips I plan to go on will be slightly off-grid, but nothing towards the expedition level where I'd travel 50+ miles just off road/ off grid....for the time being.

Hope ya'll enjoy it as I try and find / create information for everyone to use! I'll try and document it as well as I can. A lot of these projects have been inspired by mods that are available for other platforms, and mods others have done on the TSOR Facebook group page.

Lastly, I'll put some thoughts on the decisions I've made, and why I went that way. A lot of the decisions was made for a functional purpose, for when and if I needed it. Some of it,

INITIAL PURCHASE DECISION MAKING.

I purchased this vehicle Mid 2019 with the intention of making it a vehicle for road trips / camping. At this time, I was only interested in using it as a family hauler, as my family had sold the minivan around 2010, so we only had sedans. In those 9 years, we went on less road trips and it's something that I wish I had more in my life, even if it was only a handful of times a year.

Initially, I was looking at a 3 row 4runner with v8, but learned that it was a very rare spec, and the trunk space was basically non-existent. After looking around for a few weeks, I found this 05 Limited Sequoia, and jumped on it. After initial inspection, it appeared to be in good condition and the main parts of it were in working order, including the ENGINE, 4X4, TRANNY, AC, FRAME, SOUND (aftermarket with backup camera & android/apple car play), and all of the buttons, except the rear window. All the initial inspection learning was done from Youtube via Chrisfix, and any other Sequoia focused videos.

The Good

1. Frame condition is good

2. Aftermarket headunit, sound system, and backup camera.

3. Engine had good compression

4. 4HI/LO + Center diff activated.

The Bad

1. Missing fender molding (Driver side).

2. Liftgate did not work, but also sensor and trunk light didn't work (later I learned that it was missing a computer unit, and the trunk was the main issues with this vehicle in terms of electrical work)

3. AC dial rarely registers

4. Liftgate lights did not work

5. Driver / Passenger seat was starting to rip.

May 2019, after purchase.

View attachment 2602635

May 2019, two days after purchase.

Initial researched informed me that if the timing belt snaps, the whole engine is toast. My first maintenance jobs on this was to change the timing belt, water pump, pulleys, oils, including diff / transfer case. This was my first time doing this difficulty of job. My only previous experience was changing brakes, a starter in a CRV, and oil change. It was very challenging and it took me 3 days to do as I was missing some tools to brake some bolts. I also did some other jobs that were done on the way to this job.

Good References on Timing Belt DIY

The OEM Repair Manual.

Products used:

Aisin Kit

Mobil1 Synthetic Oil

Redline Gear Oil

Toyota Pink Coolant

Jobs Performed

Brake Fluid Flush

Dash Cam Install

Coolant Flush + Cap Replacement

Serpentine Belt

Timing Belt

Water Pump

Front Diff Fluid Drain + Fill

Rear Diff Fluid Drain + Fill

Transfercase Fluid Drain + Fill

View attachment 2602636 View attachment 2602637

Late May 2019, I took it to Zion to camp with friends.

It was a great time and my first time driving on non-pavement. I've never been "off road" or really on any forest roads. It was a bumpy ride, and I didn't know the concept of airing down. I thought "if has 4WD = CAN OFF ROAD".

This was also the first trip that I didn't book a site for. It was all informal, and was a dispersed site in the Forest. Loved the freedom to move sites as it was windy / raining the 2nd night.

At this time, the Sequoia is still stock, but I've been lurking the TSOR page a lot and seeing where I could go with this.

View attachment 2602647

Late June 2019

I had a misfire in cyl #8. After inspecting the coil, it had a partial crack in it. Decided to go on a budget, and went to the junkyard for a few coils. Replaced the coil in cyl 8, and also bought new spark plugs.

Used Parts

NGK Sparkplug - IFR6A11 or you can go with the Denso Sparkplug - SK20R11 // Both are recommended in the manual, but I went with NGK.

- Electrode gap: 1.0 to 1.1 mm (0.039 to 0.043 in.)

Coil Pack - #90919-02259

I decided to clean the carpet in the Sequoia. Was nasty A F.

View attachment 2602656

August 2019

Took my family to Sequoia National. Was awesome! We did encounter a bear, so that was a tad scary.

Early August 2019

One of the biggest concerns about bringing more than 5 people on a trip was storage. On one hand, you don't need too much gear, if you need to abandon the vehicle, but you still need some essentials. The current consideration is not "expedition" type trips where I need a get home bag. Most of the places I'd travel to will likely have others around and will be somewhat popular / destination spots. I'd want to go to places where there are less crowds, where there are some physical limitations to where you can go. I'm not very into rock crawling and I just want a vehicle that I can depend on to get to places and back.

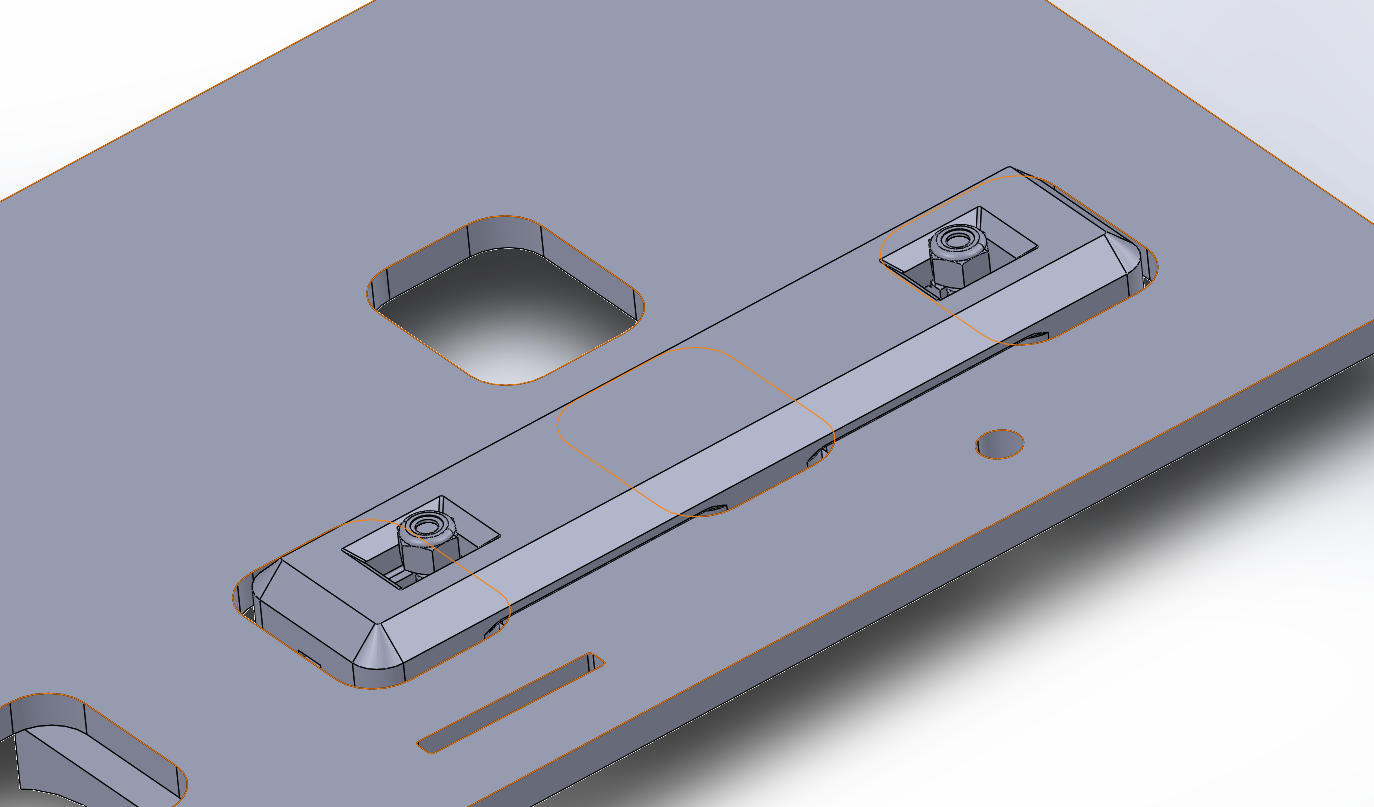

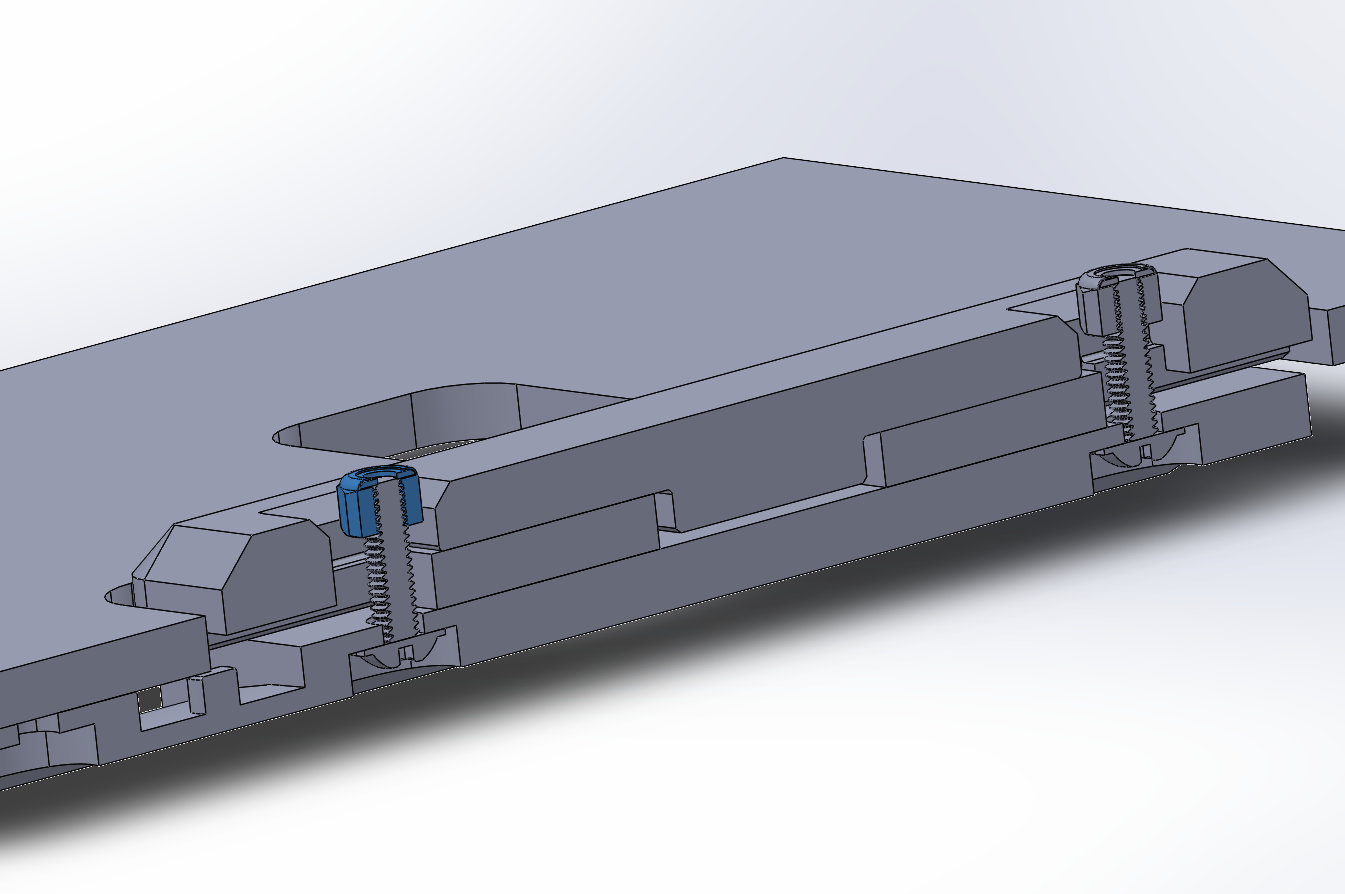

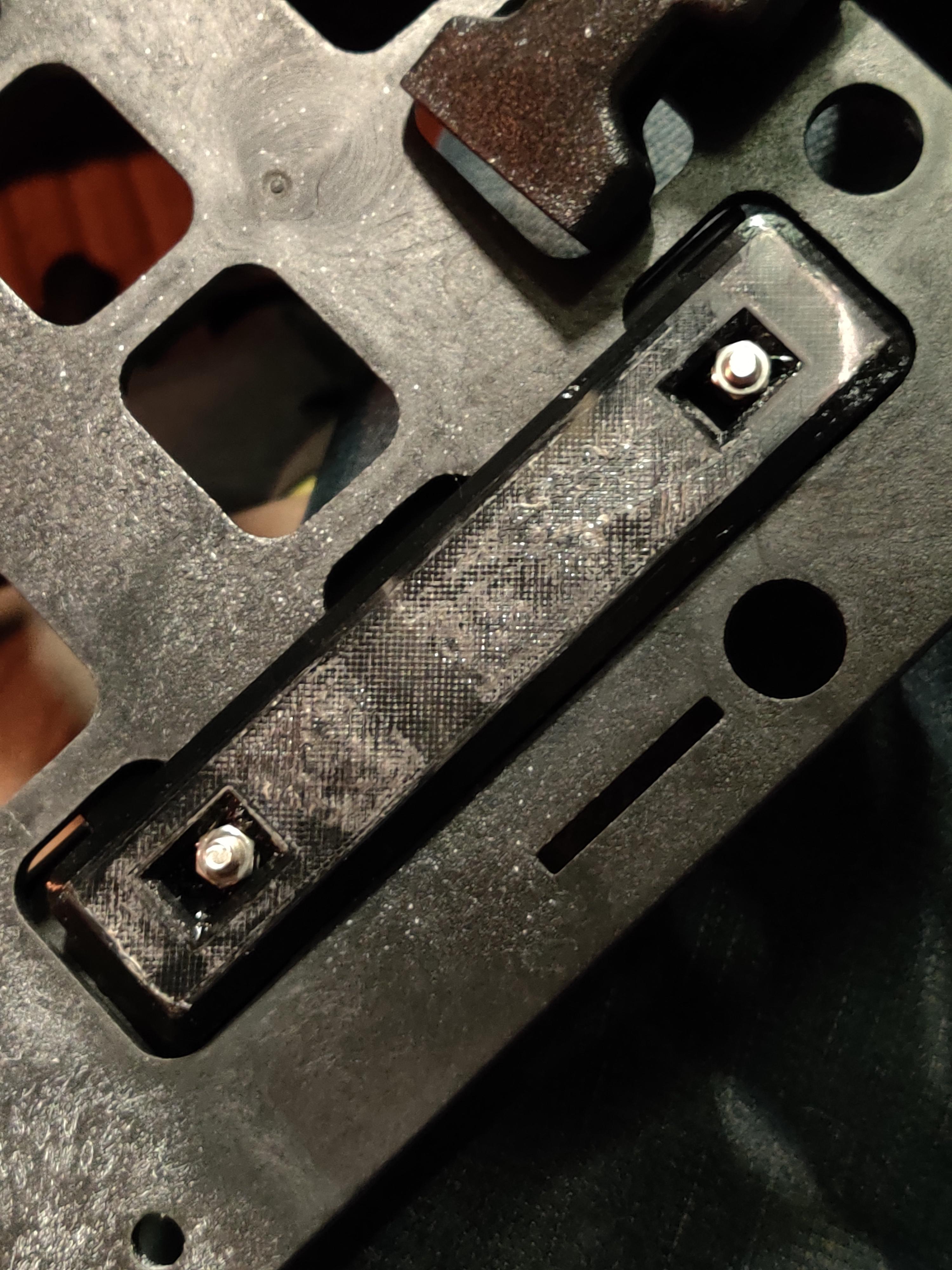

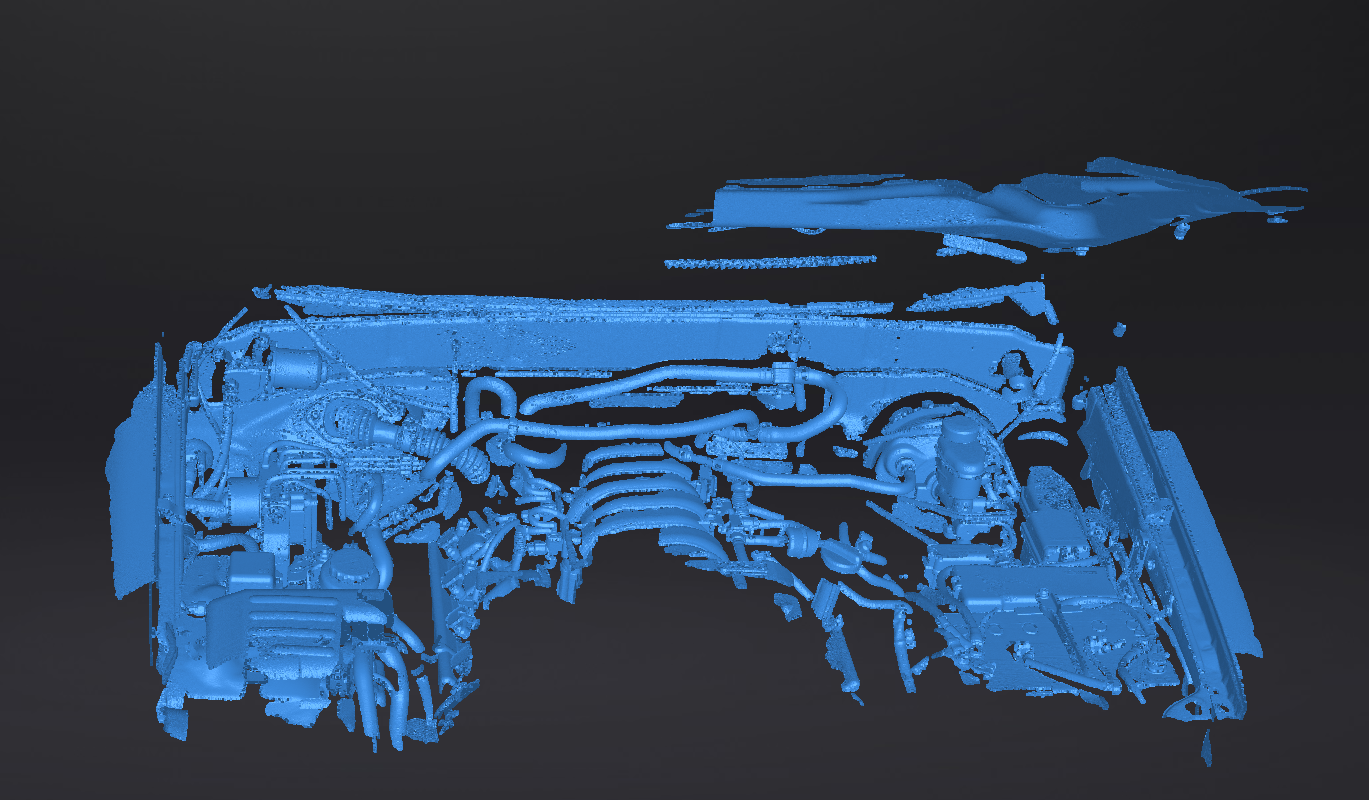

The Thule skybox was purchased used for $200, and is one of the larger ones. I also have a plano box I had, but in order to have it in the vehicle, I had to remove a chair in the 3rd row, which reduces 2 seats. I have to make some considerations on how to use part of the roof, but also maximize the rear cargo area. I don't think I need to have a lot of gear, but having to dig through it was quite cumbersome. At this point in time, I also discovered that people had drawer systems in their rigs. This would be a gamechanger, but I don't really have much experiencing wood working. On top of that, wood is very heavy, but going with aluminum is expensive, but has a good strength:weight ratio.

Mid August 2019

On my first trip, I had a big cooler attached to the rear hitch of the the Sequoia. I didn't know much about exhaust heat, and the exhaust was pointed directly at my cooler. It melted part of it so I decided to angle the exhaust. I went to a random muffler shop I found, and they did this for $20.

Thoughts in 2021, as I write this: regret doing this, and wish I had went a different direction. I think today I'd consider cutting the muffler, and then angling the piping so it aims down or to the side. Unsure how this would be achieved, but it's something I'd consider.

Sept-Oct 2019

At this point, I decided that I wanted to install ATW3's 33s (285 70 17) onto my Sequoia. I wanted it to be capable of going up roads with confidence, and also going snowboarding without the need of tire chains most of the time. We go snowboarding multiple times during the winter and chains were required at times. Safety was a huge factor in going towards this route as in my previous SUV (AWD 06 CRV), I slid on ice roads in Mammoth thinking "AWD = TRACTION". I also wanted to experience something new, learn more about working on cars, & have the ability to take on new challenges with the Sequoia.

I decided to go with a modes and economical lift kit, and also change the LBJs after reading the horrors of its failure.

Thoughts in 2021: I wish I went with something better for the front such as OME or DOBINSONS.

Parts Used

FRONT SUSPENSION

Bilstein 5100s on Bottom Notch with OME 2885 in the FRONT.

- Also had to use Energy Suspension Coil Isolator to seat the new coil for the front.

TOYOTA OEM LBJS.

SPIDERTRAX 1.25" WHEEL SPACERS.

REAR SUSPENSION

OME 60024L with OME 2865 in the REAR

- Purchased additional washers at Home Depot for the shock mount.

FREEDOM OFF ROAD UCA

- Fair price. Their CS is pretty good at responding, but I wish their information was more complete. The nut they use is non-standard and can't even be purchased at McCasterCarr.

- Part is IMPORTED.