This would be the perfect combination with a Front Runner rack! Feel free to send an email if you need help with a custom fitment!

Truck topper question

- Thread starter WanderingWinters

- Start date

-

Guest, UPDATE We went through the site migration runbook and completed all steps. We will need to complete the migration next week, but will leave the forums up for the weekend. A few days after maintenance, a major upgrade revision to the forum site will occur.

Enthusiast III

Yeah it’s the 180. At 400lbs we’re close (about 350). We got a great deal on it so we’re going to run it and see how it goes . I’ll keep you all posted on the progress.Here's some definitive advice right from the horse's mouth:

Explorer I

Engineer here. When a company rates a product for a load, they always have a Factor of Safety (FoS) built in. for example, if the topper would actually fail at 600 lbs, a FoS of 2 means they rate it at 300 lbs (600 lbs divided by 2). In most consumer products it is at least a FoS of 2 if not considerably more. So theoretically you can exceed their rating, BUT I would not come close to it. If you have ever stood on an analog scale and watched the needle as you shift your weight around even a little, you see it jumps around above and bellow your actual weight a good amount. just shifting around can put a momentary load of 50 lb or more extra load on it. Unless you literally move like a sloth it is unavoidable. And then the tent in high winds would effectively act like a sail or kite going sideways. while a topper is probably more sturdy with a load straight down on the roof than a horizontal shear load, the combined loads just add up the stresses. Just food for thought.

If it were me, I'd look to see if you can get one of those contractor racks that goes on the outside of the topper. I know my dad had one way back. That way the load is on the truck bed rails and completely avoids the topper. I would even maybe look at bed stiffeners if you were going to put a lot up there.

If it were me, I'd look to see if you can get one of those contractor racks that goes on the outside of the topper. I know my dad had one way back. That way the load is on the truck bed rails and completely avoids the topper. I would even maybe look at bed stiffeners if you were going to put a lot up there.

As Scoot brought up LIABILITIES. Even when I was involved with designing "HD Construction Racks" we advertised a load rate of 130 pounds. Just not wise to list more.

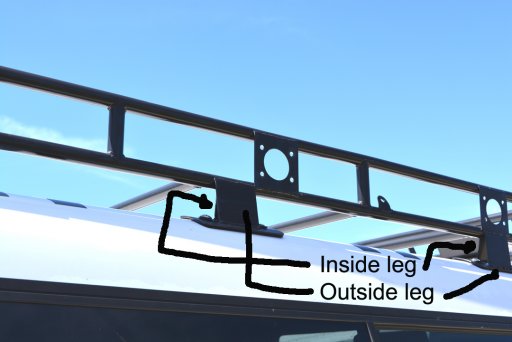

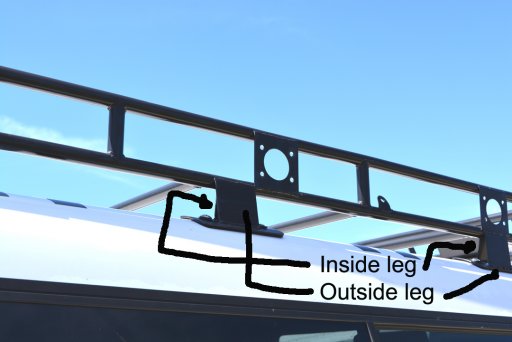

With a shell or a shell vehicle roof it is not about how strong of rack you use, it is about how load spreading the mounting points - feet of the rack are. And how many of them there are.

I designed and built the rack for my shell with three mounts per side. Each one is 7.5" long and 3" wide. They are curved - formed to match the radius, front to back, where the sides become the roof.

I have walked on my roof and on my rack, we do not have a RTT we sleep inside the shell.

At first the rack was designed for mounting awnings and carrying extra gear. And it has worked out well for that.

I think you should not have any issues with putting a RTT on a well design rack on most high quality shells.

With a shell or a shell vehicle roof it is not about how strong of rack you use, it is about how load spreading the mounting points - feet of the rack are. And how many of them there are.

I designed and built the rack for my shell with three mounts per side. Each one is 7.5" long and 3" wide. They are curved - formed to match the radius, front to back, where the sides become the roof.

I have walked on my roof and on my rack, we do not have a RTT we sleep inside the shell.

At first the rack was designed for mounting awnings and carrying extra gear. And it has worked out well for that.

I think you should not have any issues with putting a RTT on a well design rack on most high quality shells.

Make sure the shell is really attached - Over attached - to the bed rails - tops.

I have had mine move around and slide out sideways some at the back of the bed after a week long track.

I have had mine move around and slide out sideways some at the back of the bed after a week long track.

Have you seen this? SmartCap EVO Expensive but states...”holds up to 330 lbs when moving and a whopping 770 lbs when parked”

That's pretty nice! Stainless steel construction- at first I winces at how much it must weigh. But then I thought, isnt a full on suburban just as heavy with its additional roof frame, sheet metal and glass?Have you seen this? SmartCap EVO Expensive but states...”holds up to 330 lbs when moving and a whopping 770 lbs when parked”

Advocate I

Take a look at an aluminium canopy, most are designed to take loads.

When I looked for a canopy for my Hilux, that was the main criteria. Mine is tested for 2500 kg static load on the roof ( 5511 LBS ), which is ridiculous, the truck can't take only 980 kg on the back.. :)

I am not kidding some are that strong. I saw video where they put a Landcruiser 79 on top of it :)

The price difference is not huge , I paid about 5 % more compared to a good quality fiberglass. Weight of it about the same.

Mine is from a South african producer, if it is strong enough for the conditions there, should be good enough for me as well.

I am pretty sure there are aluminium canopy makers in US too.

When I looked for a canopy for my Hilux, that was the main criteria. Mine is tested for 2500 kg static load on the roof ( 5511 LBS ), which is ridiculous, the truck can't take only 980 kg on the back.. :)

I am not kidding some are that strong. I saw video where they put a Landcruiser 79 on top of it :)

The price difference is not huge , I paid about 5 % more compared to a good quality fiberglass. Weight of it about the same.

Mine is from a South african producer, if it is strong enough for the conditions there, should be good enough for me as well.

I am pretty sure there are aluminium canopy makers in US too.

Truck caps used to all be aluminum until the fiberglass started becoming more pervasive in the late 1980's. They sure do still make them.

Interestingly, I have a TracRac Van Rac and a TracRac Cap Rac that are rated for 500 lbs, whereas the fiberglass cap is rated much lower. So at least the rack itself wont be the point of failure.

Alas, the Fall River Massachusetts- based TracRac company was bought out by Thule a couple years ago. Now hardware sizes are the Nth degree different , going from SAE to Metric. And the size of the grooves as well. Still a great product, though. Just means that accessories like load stops that came on 5 year old systems dont necessarily fit on the brand new ones.

Interestingly, I have a TracRac Van Rac and a TracRac Cap Rac that are rated for 500 lbs, whereas the fiberglass cap is rated much lower. So at least the rack itself wont be the point of failure.

Alas, the Fall River Massachusetts- based TracRac company was bought out by Thule a couple years ago. Now hardware sizes are the Nth degree different , going from SAE to Metric. And the size of the grooves as well. Still a great product, though. Just means that accessories like load stops that came on 5 year old systems dont necessarily fit on the brand new ones.

In an email exchange with the VP of North American Operations he indicated the weight, before addition of accessories was 175lbs For a SB Chevrolet Colorado sized shell.That's pretty nice! Stainless steel construction- at first I winces at how much it must weigh. But then I thought, isnt a full on suburban just as heavy with its additional roof frame, sheet metal and glass?

Last edited:

That's amazing. Right in the wheelhouse of some of the fiberglass ones...cost a heck of a lot more, though...for that price I can find a GMT400 Tahoe or Suburban. Then again if I had a newer truck (newer than 2014), and a couple extra grand over the cost of fiberglass, I'd do itIn an email exchange with the VP of North American Operations he indicated the weight, before addition of accessories was 175lbs.