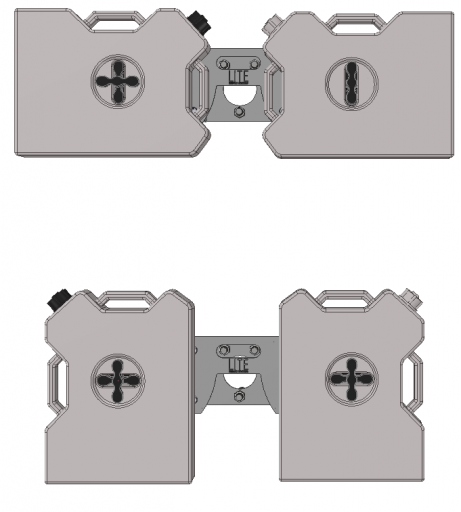

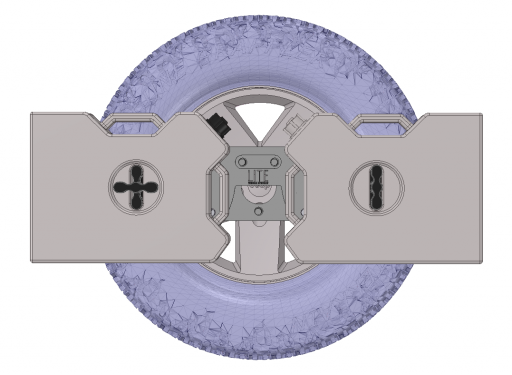

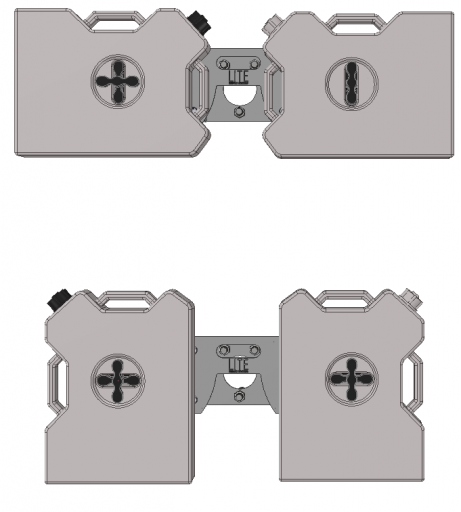

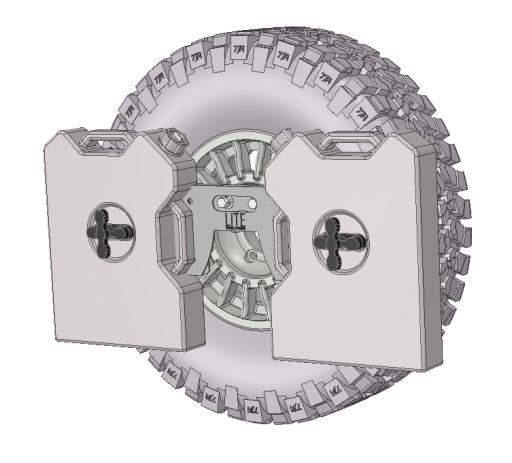

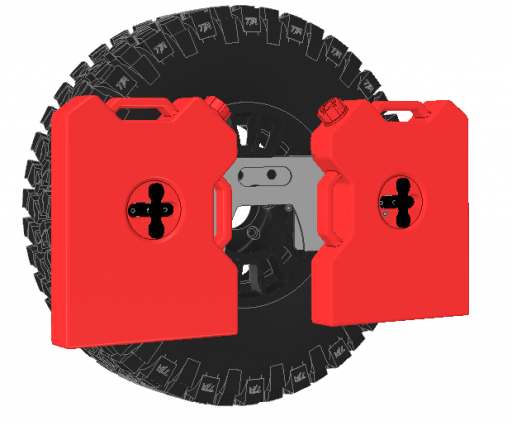

Well I am on like the 7th edition (or something) of this design. What's really a challenge is how to mount this to the top two lugs, while ensuring it is adjustable for wheel/tire combinations and also quick/easy to remove the spare tire in the event that needs to happen. This shouldn't hinder someone who needs to change their spare.

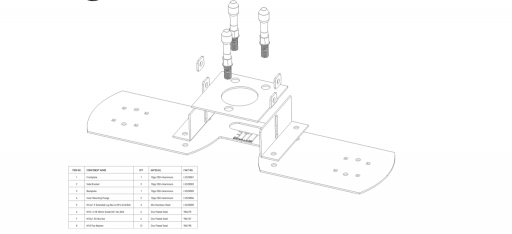

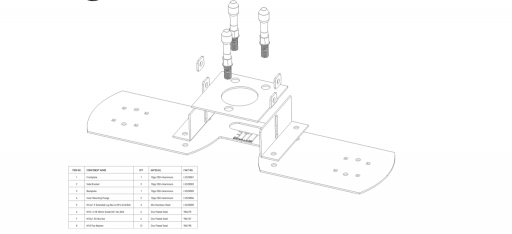

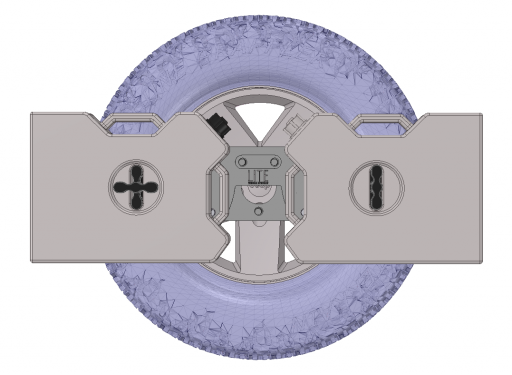

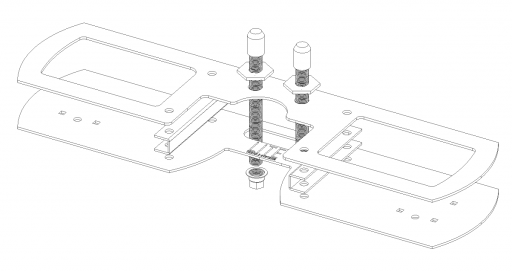

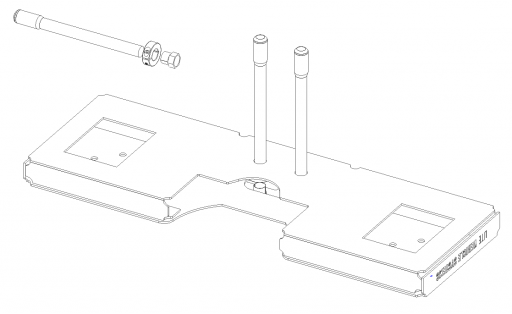

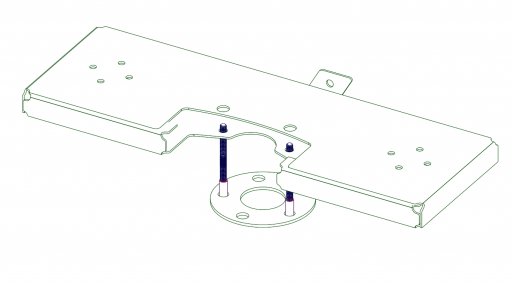

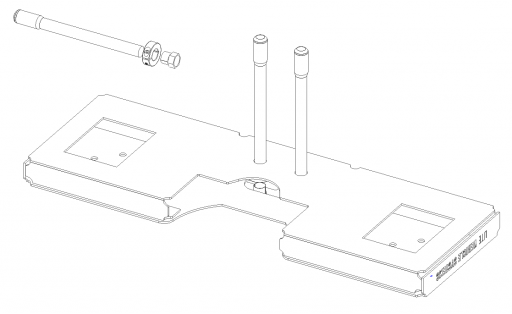

I've now gone to a 1 piece welded aluminium bracket for additional strength rather than 2 piece bolt together. Also, new mounting system to the lugs (see last photo), which will snug the bracket to your tire via torquing your lugs down (after you've correctly set the length via first time installation).

The reason for this setup is adjust-ability without having the pre-measure your tire/wheel setup (like other manufactures), while allowing attachment to virtually all wheels without the bracket itself interfering (like on the first design posted). Taking the tire off should be as simple as:

1. Break the torque on the top two extended lugs connecting the carrier to the tire.

2. Loosen the setscrew on the collar and remove the socket adapter/collar.

3. Slide the carrier off and remove the two lugs loosening by hand.

Re-installation should be:

1. Hand tighten extended lugs, loosening one-two full turns and slide carrier over the extended lugs.

2. Attach the socket adapter/collar and tighten setscrew.

3. Torque down the extended lugs, seating the carrier tightly against the tire.

Feedback is appreciated.

Feedback is appreciated.