Explorer I

- 3,680

- First Name

- Brian

- Last Name

- McGahuey

- Member #

-

23711

- Ham/GMRS Callsign

- GMRS WRMV941

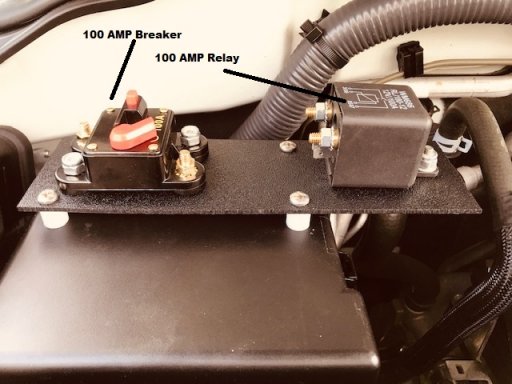

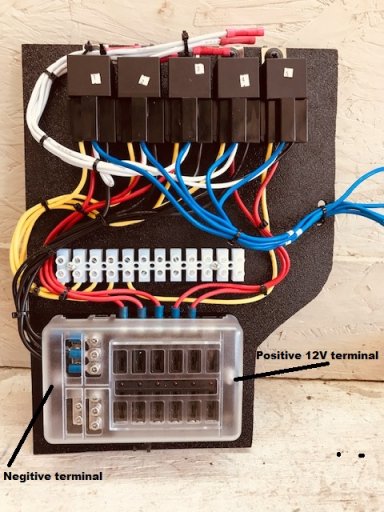

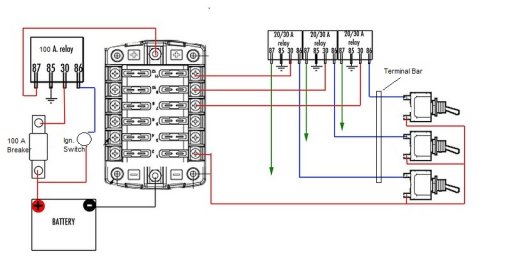

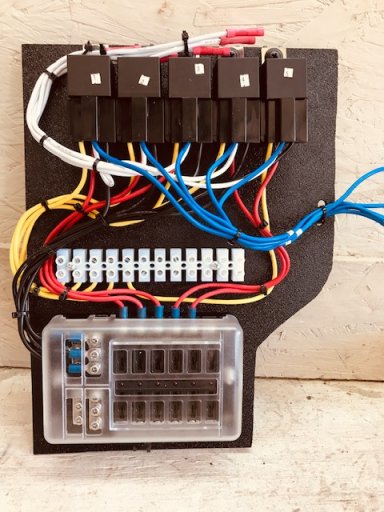

So, in my quest to build my colorado into an off the grid expedition rig, I've been on a mission to gather at least a rudimentary understanding of vehicular electrical systems.

I know that drawing a map and planning things out is key to a successful build.

Eventual accessories include a winch, off road lights (light bar, various less for use in camp), fridge, multiple radios in the truck, an inverter and compressor in the bed, and probably an onboard water system, along with additional charging ports in the cab.

I know I'll need more powerful alternator and a better battery to keep this stuff running, but right now, I'm not necessary considering a dual battery setup due to space constraints.

Now, my main question is.... When doing this, do you generally splice directly into the +/- cables coming from the battery, and run that directly to the secondary fuse box, or do you clamp o to the battery terminals, or..... Is there another option?

I know that drawing a map and planning things out is key to a successful build.

Eventual accessories include a winch, off road lights (light bar, various less for use in camp), fridge, multiple radios in the truck, an inverter and compressor in the bed, and probably an onboard water system, along with additional charging ports in the cab.

I know I'll need more powerful alternator and a better battery to keep this stuff running, but right now, I'm not necessary considering a dual battery setup due to space constraints.

Now, my main question is.... When doing this, do you generally splice directly into the +/- cables coming from the battery, and run that directly to the secondary fuse box, or do you clamp o to the battery terminals, or..... Is there another option?