Ok I have the 95% of the bumper fab work done. The only thing left is the second set of frame braces but they are going to have to wait till I build my skids. What I have now is probably more than 75% of the Tacoma bumpers out there have. The frame braces are painted and installed. The bumper is hanging from my engine hoist with the paint drying. I'm taking a break from cleaning up my mucking fess I have made. Any who y'all don't wanna read all this crap so here is some pics.

Lower frame braces welded out.

Painted and installed.

I reused the outer 6" or so of the lower valance. The clips that hold them on are part of what was damaged when I hit the coyote so I added a body bolt and Jclip to the edge of the bumper cover to hold them on now. This location sucks the valance pieces up close so no gap around the outer edges.

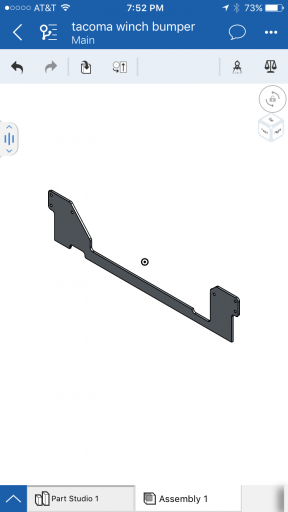

There you have it one painted bumper/winch carrier hanging from a hoist with wet paint on it.

Pay no attention to the mell of a hess you see in the background. It has been a busy last few months.