Since I don't drive the H3 as much these days I was getting a bit tired of paying for XM that was rarely used. At the same time I always appreciated having XM when on some remote trail with either no FM radio stations in range or at a minimum no good radio stations. Factor in since I installed the snorkel and did't want the antenna sticking further out I have been running without one at all. I had been using Schwarttzy's quick and simple audio input which allowed me to play songs off my phone which was nice but also wanted a better way and with the NAV disc in the factory head unit getting more and more outdated I decided it was time for a change. I don't generally do mods unless they either increase the capabilities of the truck off road or it's functionality as an overland vehicle being lived out of for a week at a time. Normally I wouldn't mention changing out the head unit but it's actually does have a benefit when wheeling but more on that later.

I had been looking at the features of CarPlay for a while and being a iOS guy liked what I saw. Factor in what you can get in a CarPlay head unit for much cheaper than a standard NAV head I decided that was the route I was going to go. Did a lot of research and comparison and settled on the Kenwood DDX6702S. Could have gone with something with a slightly larger screen or more bells and whistles but I didn't need them and for the money this had everything I was looking for.

Kenwood DDX6702S with 6.2" display

CarPlay on the DDX6702S

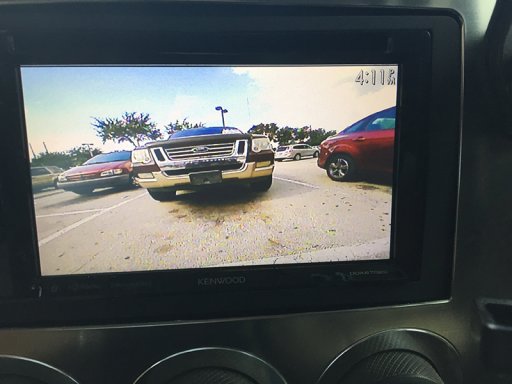

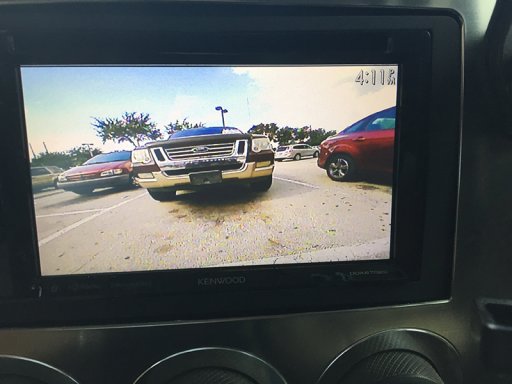

Added the rear camera to the obviously scratched of bumper. Will see how I like this position of if I want to change it when I go to a new bumper.

One feature I like about this head unit (I am sure it's becoming more common if not on most now) is that I can pushing the volume knob for a few seconds at any time and pull up the rear camera view, no need to be in reverse. This will be handy when following one of the cardinal rules of wheeling, always keep the guy behind you in view.

I added a USB port to the driver side of the center console below the center stack. This is used to plug the phone into the unit for CarPlay to work but you can also read media off a USB device. Have not yet tried but need to see if I can view video files recorded on to SD cards by the DVR using a USB SD card reader.

For better FM reception since I am was not running an antenna I installed an amplified antenna from AntennaX.com. Ran the cable up the passenger A-pillar and mounted the antenna in the upper right corner of the inside of the windshield. Using it out in the Ocala forest a few weeks ago I would say the reception is at least as good as it ever was with the stock antenna and there is nothing to hang up on tree limbs.

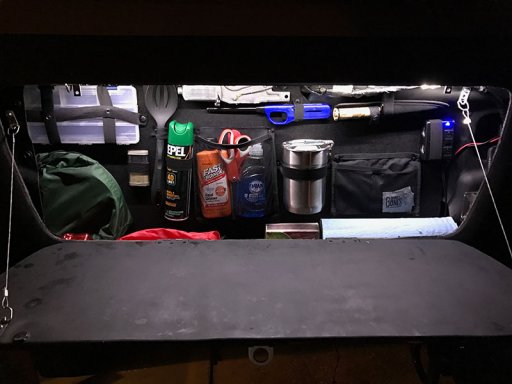

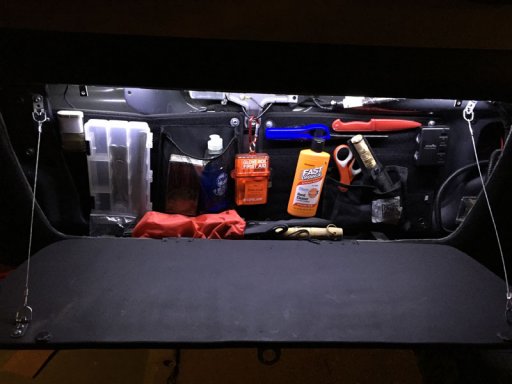

Now the feature that really influenced my decision to go with this unit and will be a benefit when wheeling was the ability to have second forward facing camera. I installed the camera in the center of the plastic facia just above the winch bumper.

When wheeling I can pull up this camera when say cresting a hill or dropping off a ledge where you can not see anything in front of the truck or picking a line through some rocks. I can think of many times in the past where this would have come in handy and should frequently eliminate the need for a spotter.

Just a parking lot view but you get the idea of how this will be handy on the trail.

With the limited use I have had with it so far I am very happy with the selection of this unit. Has the features I needed/wanted and the NAV will be much better with CarPlay since it's constantly updated and has traffic. Hopefully they will continue to add more features and open it up more and more to developers. Would like to see them allow apps such as Dash Command which i am using on the iPad now to read my OBDII reader. Would be nice if that was on the head unit all the time.