Advocate I

First time to MOAB and it was GREAT! 2282.3 miles on the clock and home again last night. Trip average of 18.1 MPG. The long desert stretches made up for the trail crawling. Nothing was on the roof there and back, I had the luxury of putting the gas cans and such in a friends truck and only putting things on the roof for trail running. We found a great campsite along the river on Potash Road. It was centrally located and near town and near the trails we had planned. No issues with the WJ at all on this trip.

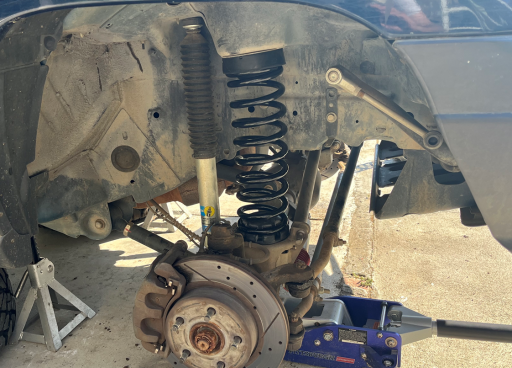

Prep for the trip was to fix a pull to the right and right tire wear. Figured the stock control arm bushings were toast. Right upper was torn and disintegrating, and lower front bushings on both arms were collapsed. Found a few other things along the way as well. Found right shock was internally damaged as the compression resistance was very little and rebound was incredibly slow. Both sides of the JKS track showed a little movement even with 9/16 hardware. So tired of replacing the JKS bushings before and after every trip!

Installed Core 4x4 upper and lower arms with good old Clevite bushings, Trail Forged track bar, and Bilstein shocks all the way around. Added 1/2 inch to the front bumpstops for track bar clearance. Tire balance, rotation, and a final good alignment. Only red in the alignment specs was the caster at - 4.6 degrees (right on target!).

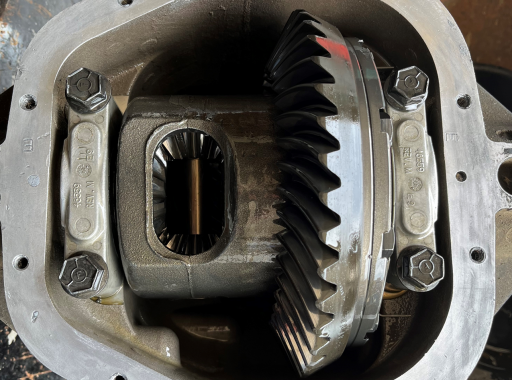

Much more stable with the Trail Forged track Bar, much less track shift and bump steer while disconnected as well. As expected on road was much improved and off road and disconnected it had lazier flex due to intact and fresh bushings. Front and rear differential bearing noises continue but nothing changed pitch or got louder. The usual pops and groans in 4 low. Could have definitely made use of fresh tires when we encountered mud, snow, and ice. They have about 1/3 tread left, not enough for best traction but still have a lot of highway miles left on them.

Trail repairs included tightening a lower control arm bolt on a TJU way out past hardscrabble Hill. The bracket had separated 1/4 inch and the arm was hammering back and forth. Second fix was the battery strap came undone on a 4 Runner and the chassis ground ripped out. He was lucky there were no shorts. Secured the battery and made/installed a new ground strap and he was good to go. Third was a lost end link bolt on a JKU Rubicon. A trip to Napa and he was good to go.

I'll get some pics up once I catch up at work and deal with liberating them from my iPhone.

Prep for the trip was to fix a pull to the right and right tire wear. Figured the stock control arm bushings were toast. Right upper was torn and disintegrating, and lower front bushings on both arms were collapsed. Found a few other things along the way as well. Found right shock was internally damaged as the compression resistance was very little and rebound was incredibly slow. Both sides of the JKS track showed a little movement even with 9/16 hardware. So tired of replacing the JKS bushings before and after every trip!

Installed Core 4x4 upper and lower arms with good old Clevite bushings, Trail Forged track bar, and Bilstein shocks all the way around. Added 1/2 inch to the front bumpstops for track bar clearance. Tire balance, rotation, and a final good alignment. Only red in the alignment specs was the caster at - 4.6 degrees (right on target!).

Much more stable with the Trail Forged track Bar, much less track shift and bump steer while disconnected as well. As expected on road was much improved and off road and disconnected it had lazier flex due to intact and fresh bushings. Front and rear differential bearing noises continue but nothing changed pitch or got louder. The usual pops and groans in 4 low. Could have definitely made use of fresh tires when we encountered mud, snow, and ice. They have about 1/3 tread left, not enough for best traction but still have a lot of highway miles left on them.

Trail repairs included tightening a lower control arm bolt on a TJU way out past hardscrabble Hill. The bracket had separated 1/4 inch and the arm was hammering back and forth. Second fix was the battery strap came undone on a 4 Runner and the chassis ground ripped out. He was lucky there were no shorts. Secured the battery and made/installed a new ground strap and he was good to go. Third was a lost end link bolt on a JKU Rubicon. A trip to Napa and he was good to go.

I'll get some pics up once I catch up at work and deal with liberating them from my iPhone.