On my last camping trip i used my DIY kitchen for the first time and it worked great.

But because i had to place it on the tailgate getting to my other gear in the back of the car

was not that easy of course.

www.overlandbound.com

www.overlandbound.com

So this is what i made:

And this is how i made it..

I decided to build a pull-out platform to make life a bit easier on longer trips..

Because i like to keep the car relative light weight since it's my daily driver i did not want to use

a (heavy) wood base plate in the back of the car to bolt the pull-out platform on.

So after some thinking i decided to use a 2040 aluminum extrusion as a crossmember

(sorry don't know a better word in English for it) and bolt it to the factory tie down nuts behind the back seats.

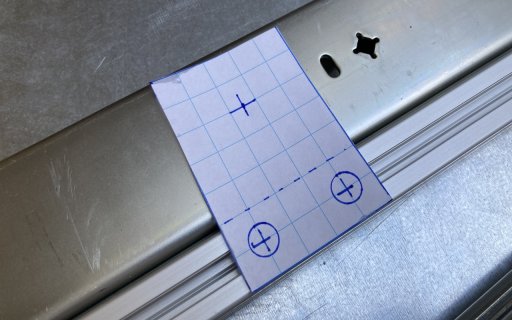

Because they lay a bit deeper in the floor i had to fabricate two solid spacers.

This chunky block is what i had laying around.. Try and use stuff i already have.

Something like that.. two solid spacers to bolt the crossmember on too.

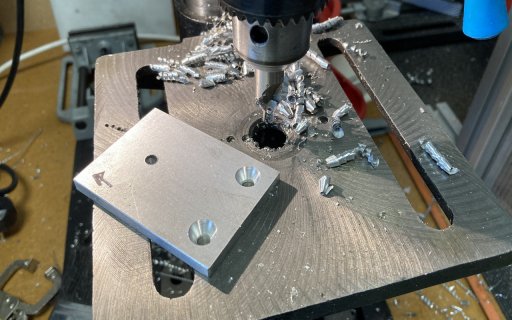

So with that sorted i now could figure out how to build the pull-out platform and how to bolt it to the crossmember.

Taking a couple 1000 measurements lol.

After al the measuring i had a fairly clear idea how i was going to build the platform and the dimensions

i can use.

To be continued..

But because i had to place it on the tailgate getting to my other gear in the back of the car

was not that easy of course.

"8020" KITCHEN MODULE, First time use!

He guys! Last weekend i finally had the chance to use and test the kitchen module i made some time ago. (Build here: "8020" KITCHEN MODULE..) The kitchen module is basically just a frame out of aluminum extrusion with 2 drawers made from euro style (60x40 centimeters) storage boxes and a fixed...

So this is what i made:

And this is how i made it..

I decided to build a pull-out platform to make life a bit easier on longer trips..

Because i like to keep the car relative light weight since it's my daily driver i did not want to use

a (heavy) wood base plate in the back of the car to bolt the pull-out platform on.

So after some thinking i decided to use a 2040 aluminum extrusion as a crossmember

(sorry don't know a better word in English for it) and bolt it to the factory tie down nuts behind the back seats.

Because they lay a bit deeper in the floor i had to fabricate two solid spacers.

This chunky block is what i had laying around.. Try and use stuff i already have.

Something like that.. two solid spacers to bolt the crossmember on too.

So with that sorted i now could figure out how to build the pull-out platform and how to bolt it to the crossmember.

Taking a couple 1000 measurements lol.

After al the measuring i had a fairly clear idea how i was going to build the platform and the dimensions

i can use.

To be continued..

Last edited: