Member I

9 1\2 month build, 6 months of research

Solar: Renogy, 2 100watt portable suit case panels w\ branch connector to run both parallel or single panel, Renogy 30 amp Wanderer Charge Controller w\ Battery Temperature Sensor, 20ft 10 awg cable

Battery: VMax Tank 125ah AGM Battery

Suspension: Smooth Ride 3 leaf springs 1450lb. capacity w\ Monroe Shock & 2000lb axle

Tires & Wheels: General Grabber AT II & US Wheels 15"x 8" 4.5" on 5 lug (I media blasted & had powder coated satin black)

Tent: Smittybilt 2783 RTT w\ Exped Duo 10 Queen Size extra long extra wide self inflating mattress w\ CVT Anti Condensation Matt & Compact Camping Concept Shoe Hammock

Awning: Tuff Stuff 4x4 4.5ft x 6ft w\ Tuff Stuff 4x4 Sun Shade Wall

Paint: PPG Automotive, DP Epoxy Primer, Omni Base matched to Cerakote Coyote Tan, Concept Gloss w\flattener added.

Bedliner: Defender Pro, orange peel texture 10" up on the exterior tub, tongue box & face of fenders, heavy texture inside the bed & tailgate. (all sprayed)

Frame: modified reinforced Harbor Freight Super Duty w\custom fabricated tongue & spare tire mount. (all welded)

Body: Dinoot M Series M416 tub kit w\ CJ Jeep style tailgate w\hidden tailgate latches

Fenders: Jeep Style Aluminum length: 36" height: 18 1/4" width: 10" cut to size & scribed to fit, Defender Pro Bedliner sprayed on the faces.

Bed Floor: 3\16" Smooth Aluminum sand blasted w\ Defender Pro Bedliner sprayed inside, exterior underneath Automotive Undercoater sprayed

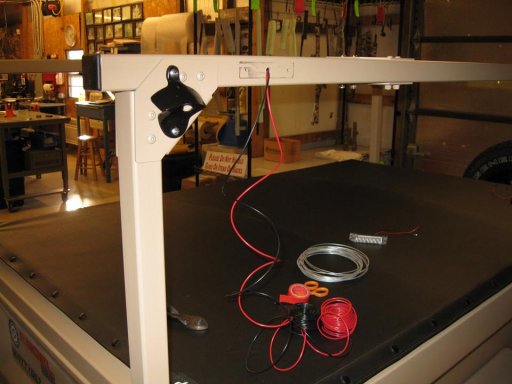

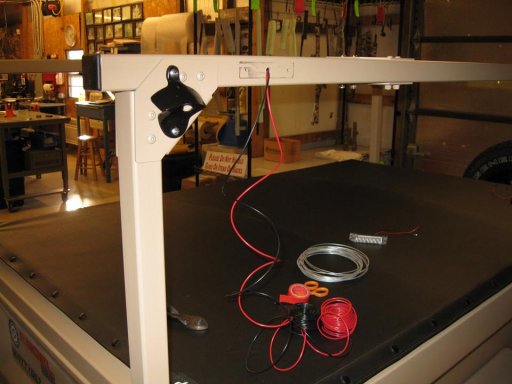

Tongue Box: Harbor Freight 2-3/4 cu. ft, 3 12v. outlets & 1 12v. rocker switch, Pro Defender Bebliner sprayed up 10" & painted to match trailer. Houses all electrical & solar system.

Heating: Proplex Heat Source H2000 Tent Furnace

Tent Rack: Compact Camping Concept "No Weld" Gusset's w\ 1 1\2" thick wall tubing, bolted & welded

Jacks: Pro Series Round 2000lb Pipe Mount Swivel Jack w/ Footplate side crank

Propane Bottle Mount: AT Overland Equipment 5lb Propane Cylinder Bracket painted to match the trailer.

Extra fuel Storage: fabricated plate w\ bracing for Smittybilt Jerry Can Mount & Scepter 5gal Jeep Can

Charging System: Noco Genius 10 amp Single Bank On Board Battery Charger

Tonneau Cover: Downey Products.

Rugged Ridge Hi-Lift Jack Mount w\ 42" Bulldog Hi-Lift Jack

Solar: Renogy, 2 100watt portable suit case panels w\ branch connector to run both parallel or single panel, Renogy 30 amp Wanderer Charge Controller w\ Battery Temperature Sensor, 20ft 10 awg cable

Battery: VMax Tank 125ah AGM Battery

Suspension: Smooth Ride 3 leaf springs 1450lb. capacity w\ Monroe Shock & 2000lb axle

Tires & Wheels: General Grabber AT II & US Wheels 15"x 8" 4.5" on 5 lug (I media blasted & had powder coated satin black)

Tent: Smittybilt 2783 RTT w\ Exped Duo 10 Queen Size extra long extra wide self inflating mattress w\ CVT Anti Condensation Matt & Compact Camping Concept Shoe Hammock

Awning: Tuff Stuff 4x4 4.5ft x 6ft w\ Tuff Stuff 4x4 Sun Shade Wall

Paint: PPG Automotive, DP Epoxy Primer, Omni Base matched to Cerakote Coyote Tan, Concept Gloss w\flattener added.

Bedliner: Defender Pro, orange peel texture 10" up on the exterior tub, tongue box & face of fenders, heavy texture inside the bed & tailgate. (all sprayed)

Frame: modified reinforced Harbor Freight Super Duty w\custom fabricated tongue & spare tire mount. (all welded)

Body: Dinoot M Series M416 tub kit w\ CJ Jeep style tailgate w\hidden tailgate latches

Fenders: Jeep Style Aluminum length: 36" height: 18 1/4" width: 10" cut to size & scribed to fit, Defender Pro Bedliner sprayed on the faces.

Bed Floor: 3\16" Smooth Aluminum sand blasted w\ Defender Pro Bedliner sprayed inside, exterior underneath Automotive Undercoater sprayed

Tongue Box: Harbor Freight 2-3/4 cu. ft, 3 12v. outlets & 1 12v. rocker switch, Pro Defender Bebliner sprayed up 10" & painted to match trailer. Houses all electrical & solar system.

Heating: Proplex Heat Source H2000 Tent Furnace

Tent Rack: Compact Camping Concept "No Weld" Gusset's w\ 1 1\2" thick wall tubing, bolted & welded

Jacks: Pro Series Round 2000lb Pipe Mount Swivel Jack w/ Footplate side crank

Propane Bottle Mount: AT Overland Equipment 5lb Propane Cylinder Bracket painted to match the trailer.

Extra fuel Storage: fabricated plate w\ bracing for Smittybilt Jerry Can Mount & Scepter 5gal Jeep Can

Charging System: Noco Genius 10 amp Single Bank On Board Battery Charger

Tonneau Cover: Downey Products.

Rugged Ridge Hi-Lift Jack Mount w\ 42" Bulldog Hi-Lift Jack

Last edited: