Steward II

- 10,598

- First Name

- Dave

- Last Name

- Addington

- Member #

-

10123

- Ham/GMRS Callsign

- KN6BKH

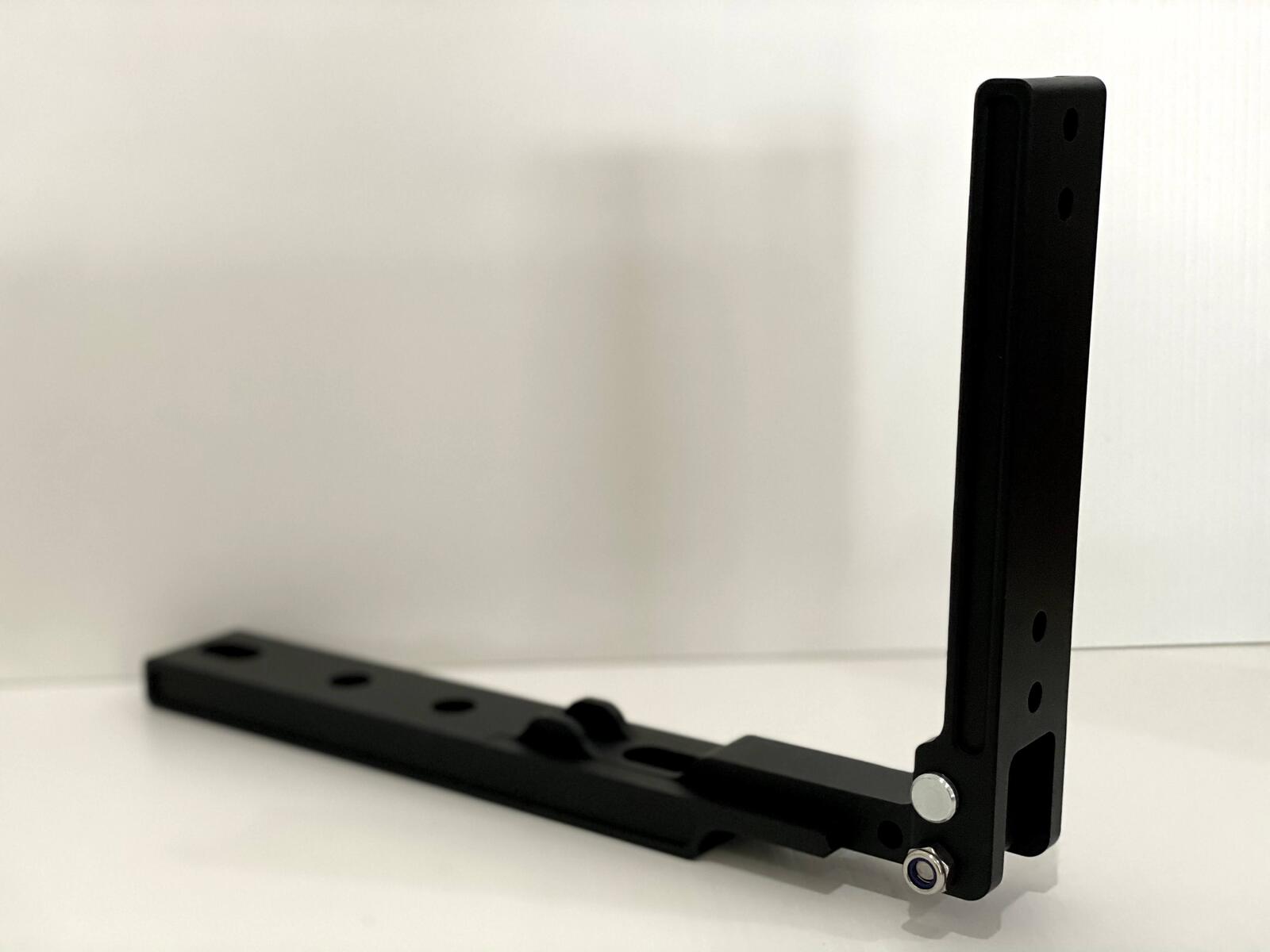

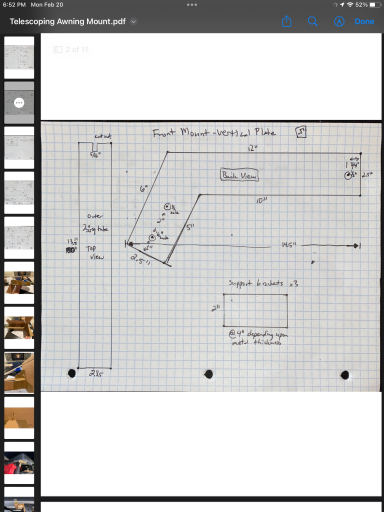

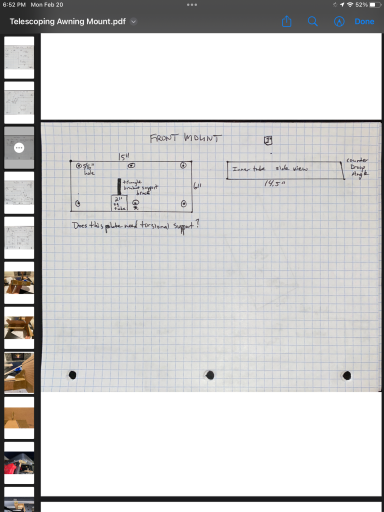

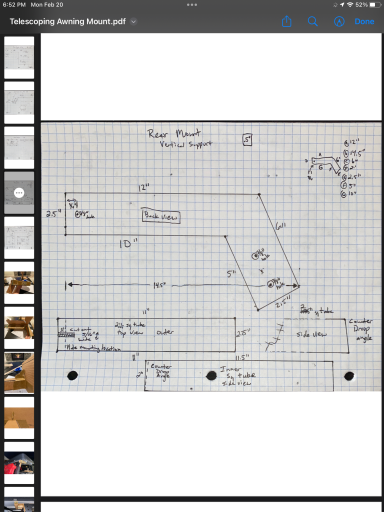

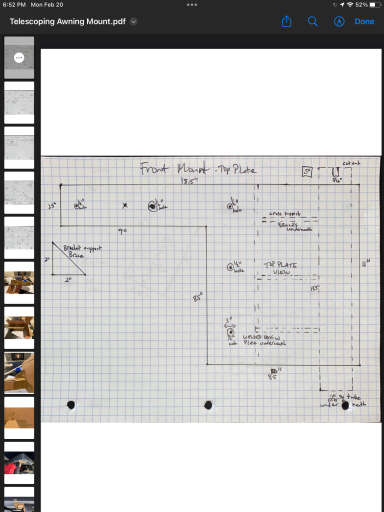

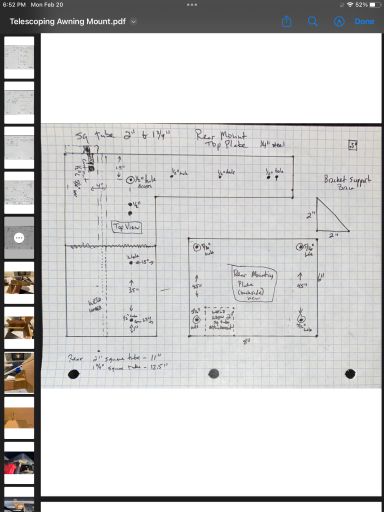

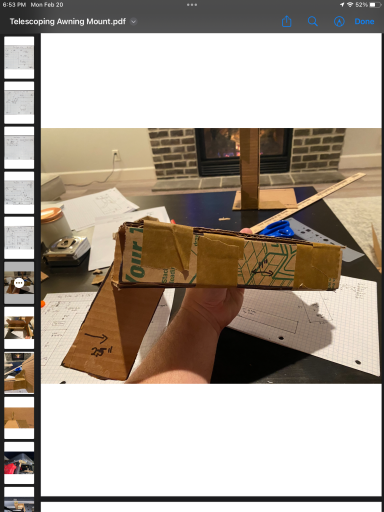

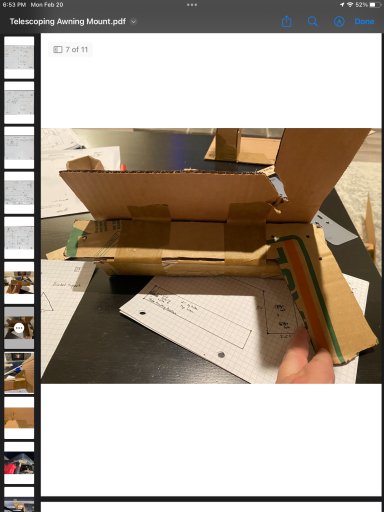

I am working on adding a 270 awning to my rack that has an iKamper. The challenge is that an iKamper shell HEAVES out to the drivers side on its hinges as it opens to the passenger side. So one can’t place the awning too close to the tent (on the drivers side) or they will interfere with each other. So I’m mocking up telescoping mounts. The idea is to be able to tuck the awning up tight next to the tent in transport, then slide it out 7” away from the tent to deploy the awning and open the tent. I am going to use square tubes that nests inside of each other to function as the telescoping mechanism, simple and durable. I used this method for my privacy tent on a prior build and it worked well.

I didn’t want a 90” awning hanging out 7-8” away from the tent all the time which I why this project was born.

My progress so far

(Skip to the end to see the finished project)

www.overlandbound.com

www.overlandbound.com

Preview shot!

How it began

I didn’t want a 90” awning hanging out 7-8” away from the tent all the time which I why this project was born.

My progress so far

(Skip to the end to see the finished project)

DIY 270 telescoping awning mounts for rack with an iKamper RTT

BTW I have no idea what the music is playing the background. Must have been off the tv

Preview shot!

How it began

Last edited: