Member III

One of the things I dislike is airing down and airing up. I run about 50 psi in the fronts and 70 psi in the rears for highway driving. I usually air down to between 25-30 psi all around for dirt. I know I could get some Staun's but I haven't, and end up kneeling and adjusting each tire in sequence. And the Staun's don't help with airing up.

So, after seeing a few kits for exorbitant price (to me), I decided to make a 4-tire system.

About $90 total for 50' feet of air hose from harbor freight, and a handful of fittings from Zoro and Amazon, and a little time resulted in this:

The blue hose attaches to the compressor. The brass manifold distributes the air to either side of the van. I also installed a schrader valve at the manifold so I could monitor the pressure with a regular tire gauge. This turns out not to be necessary, as I can monitor the pressures via the TPMS display on the dash. The hoses attach to the tires with quick release schrader heads that shut off when not attached, creating a closed system. A quarter turn valve allows me to shut off the pressure to all 4 tires at once. To deflate, I just close the valve, attach the hoses to the tires, and open the valve (with the blue hose not attached to the compressor).

The main benefits are twofold. First, the pressure in the system is equalized, so all tires default to the same pressure. When airing down, I run all the tires at the same pressure, so this is ideal. When airing up, I can run all 4 tires up to 50 psi, unhook the fronts, and run the rears up to 70 psi.

Second, I don't have to babysit each tire. No more kneeling and constantly checking pressures. I can do other things, or just relax, while inflating or deflating. This makes the whole process much more appealing.

Some people will say that this is something totally superfluous and might even make fun of it, but for me it makes airing up and airing down much less of a chore, and therefore I am more likely to do it. This, to me, is invaluable.

2 components are important. First, good quick release schrader valves for the tires. the ones I got were expensive. At about $11 each, they were the single-most expensive component of the system. But the cheap ones simply don't work well, so it was worth it.

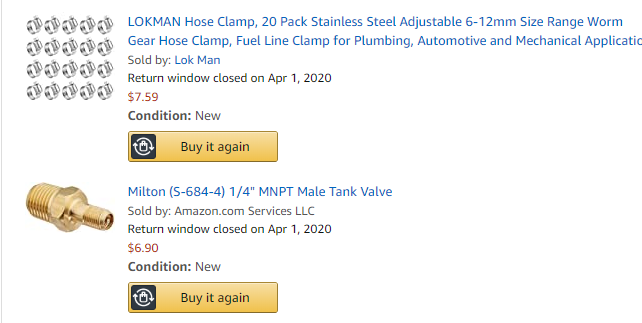

Second, good hose clamps. I had one fail, which renders the whole system unusable. Luckily, some bailing wire fixed that problem, at least until I got home.

The only thing I would add is an in-line pressure gauge if I didn't have TPMS, so I wouldn't have to keep manually checking the pressure with a tire gauge.

Here's a diagram with all the parts

Total price was just over $90. You might be able to source some of the parts cheaper if you look around.

So, after seeing a few kits for exorbitant price (to me), I decided to make a 4-tire system.

About $90 total for 50' feet of air hose from harbor freight, and a handful of fittings from Zoro and Amazon, and a little time resulted in this:

The blue hose attaches to the compressor. The brass manifold distributes the air to either side of the van. I also installed a schrader valve at the manifold so I could monitor the pressure with a regular tire gauge. This turns out not to be necessary, as I can monitor the pressures via the TPMS display on the dash. The hoses attach to the tires with quick release schrader heads that shut off when not attached, creating a closed system. A quarter turn valve allows me to shut off the pressure to all 4 tires at once. To deflate, I just close the valve, attach the hoses to the tires, and open the valve (with the blue hose not attached to the compressor).

The main benefits are twofold. First, the pressure in the system is equalized, so all tires default to the same pressure. When airing down, I run all the tires at the same pressure, so this is ideal. When airing up, I can run all 4 tires up to 50 psi, unhook the fronts, and run the rears up to 70 psi.

Second, I don't have to babysit each tire. No more kneeling and constantly checking pressures. I can do other things, or just relax, while inflating or deflating. This makes the whole process much more appealing.

Some people will say that this is something totally superfluous and might even make fun of it, but for me it makes airing up and airing down much less of a chore, and therefore I am more likely to do it. This, to me, is invaluable.

2 components are important. First, good quick release schrader valves for the tires. the ones I got were expensive. At about $11 each, they were the single-most expensive component of the system. But the cheap ones simply don't work well, so it was worth it.

Second, good hose clamps. I had one fail, which renders the whole system unusable. Luckily, some bailing wire fixed that problem, at least until I got home.

The only thing I would add is an in-line pressure gauge if I didn't have TPMS, so I wouldn't have to keep manually checking the pressure with a tire gauge.

Here's a diagram with all the parts

Total price was just over $90. You might be able to source some of the parts cheaper if you look around.

|

| This image has been resized. Click this bar to view the full image. |