Well, I made the order, and, a week or so later, it came...

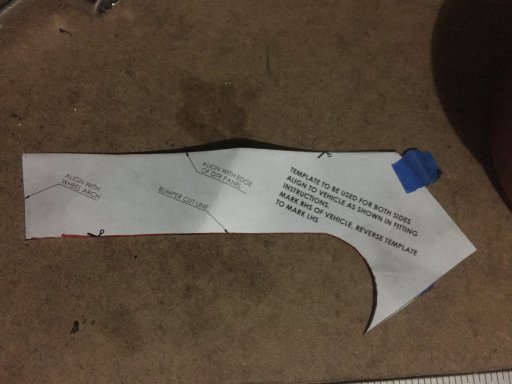

There are a few things in the instructions that area a little daunting, but no more than the install of the CBI rear bumper on my 4runner, so I think I'll be fine. As expected the fit and finish on the bumper is exceptional. Many of the items have been individually boxed and labeled which should aid in the installation. A perusal of the instructions suggests everything has been covered fairly well. I wish they would have pre-drilled for the front bumper sensors, but they included a template to drill the appropriate holes so I'll see how that goes.

There's a lot of videos/blogs on getting the ARB bumper installed on 4runners and Tacomas, but haven't found any on the Tundra so far (a few "after" shots).

When I put together my Tacoma with the Relentless Fabrication front bumper, I installed a combo light bar. It was exceptionally useful during several trips on the backcountry dirt roads where we were traveling in the dark searching for a particular campground/campsite. I have been looking at the 7" and 9" round LED lights that are commonly seen with this particular style of bumper, but the cost of the more well known brands is a little staggering to say the least. I've found a few Nilight (or similar) ones on Amazon which are reasonably priced, but many of them have some less than stellar long term reports. I did a quick measurement of the single row LED light bar in my current Southern Style Offroad bumper (30") and it appears as it will fit in the center, but I would have to drill in some mounting points. Additionally, I will have to see if it would interfere with how/where the winch controller is mounted.

Once I get the SSO bumper off, I'll be posting it for sale, so if anyone's interested, or knows of someone who might want one, let me know. If I can't get the light bar situated to my liking I'll be including it (and the wiring harness) with the bumper. I really liked the SSO bumper, on the Tundra and on my 4runner, and I think the company is top notch. Hopefully I can find it a good home.

I'm looking forward to the install...

There are a few things in the instructions that area a little daunting, but no more than the install of the CBI rear bumper on my 4runner, so I think I'll be fine. As expected the fit and finish on the bumper is exceptional. Many of the items have been individually boxed and labeled which should aid in the installation. A perusal of the instructions suggests everything has been covered fairly well. I wish they would have pre-drilled for the front bumper sensors, but they included a template to drill the appropriate holes so I'll see how that goes.

There's a lot of videos/blogs on getting the ARB bumper installed on 4runners and Tacomas, but haven't found any on the Tundra so far (a few "after" shots).

When I put together my Tacoma with the Relentless Fabrication front bumper, I installed a combo light bar. It was exceptionally useful during several trips on the backcountry dirt roads where we were traveling in the dark searching for a particular campground/campsite. I have been looking at the 7" and 9" round LED lights that are commonly seen with this particular style of bumper, but the cost of the more well known brands is a little staggering to say the least. I've found a few Nilight (or similar) ones on Amazon which are reasonably priced, but many of them have some less than stellar long term reports. I did a quick measurement of the single row LED light bar in my current Southern Style Offroad bumper (30") and it appears as it will fit in the center, but I would have to drill in some mounting points. Additionally, I will have to see if it would interfere with how/where the winch controller is mounted.

Once I get the SSO bumper off, I'll be posting it for sale, so if anyone's interested, or knows of someone who might want one, let me know. If I can't get the light bar situated to my liking I'll be including it (and the wiring harness) with the bumper. I really liked the SSO bumper, on the Tundra and on my 4runner, and I think the company is top notch. Hopefully I can find it a good home.

I'm looking forward to the install...