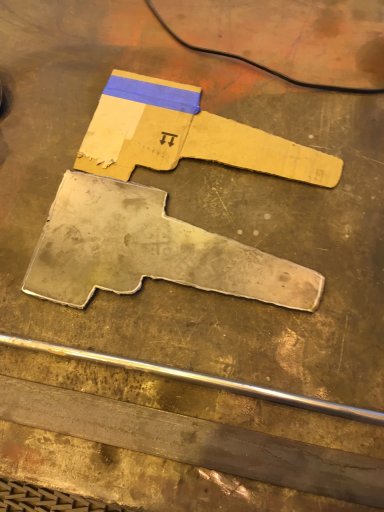

Not wanting crazy weight, but not wanting to spend crazy money either so I am making my own. Center section is a pre made Westin winch tray made out of 1/4 inch steel. The sides that I am making to bolt onto it will be made of aluminum. Think I am going to go with 3/16. Not wanting to cut the frame so I am making the mounts so they can be bolted onto factory locations. All mounts will be made of 1/4 steel.