Thanks for the tips guys. Much appreciated. I've also considered a Rockwell, or Detroit rear end from another school bus; have seen a good number already in 4.56 (what the D60 front is). Obviously I'd be adapting from 8x6.5 to a 10 bolt "big truck" pattern to match the rear, if I go with such a large axle. I've been mulling over the D80 vs D70 vs 14-bolt as well, and will probably end up with the latter if I don't go big truck stuff, if only because the D70 and D80 are a lot more difficult to find around here.

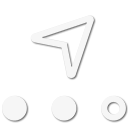

If anyone has a steering arm for a Dana 60, I'd be interested in taking it off your hands, by the way. At some point in this axle's life, someone welded the nuts and studs together, and to the steering arm. I don't know what they were thinking, but it was hot enough to gouge halfway through the studs. The steering arm was even tacked to the knuckle and it was a pain in the ass to remove. Needless to say, I need a new one...

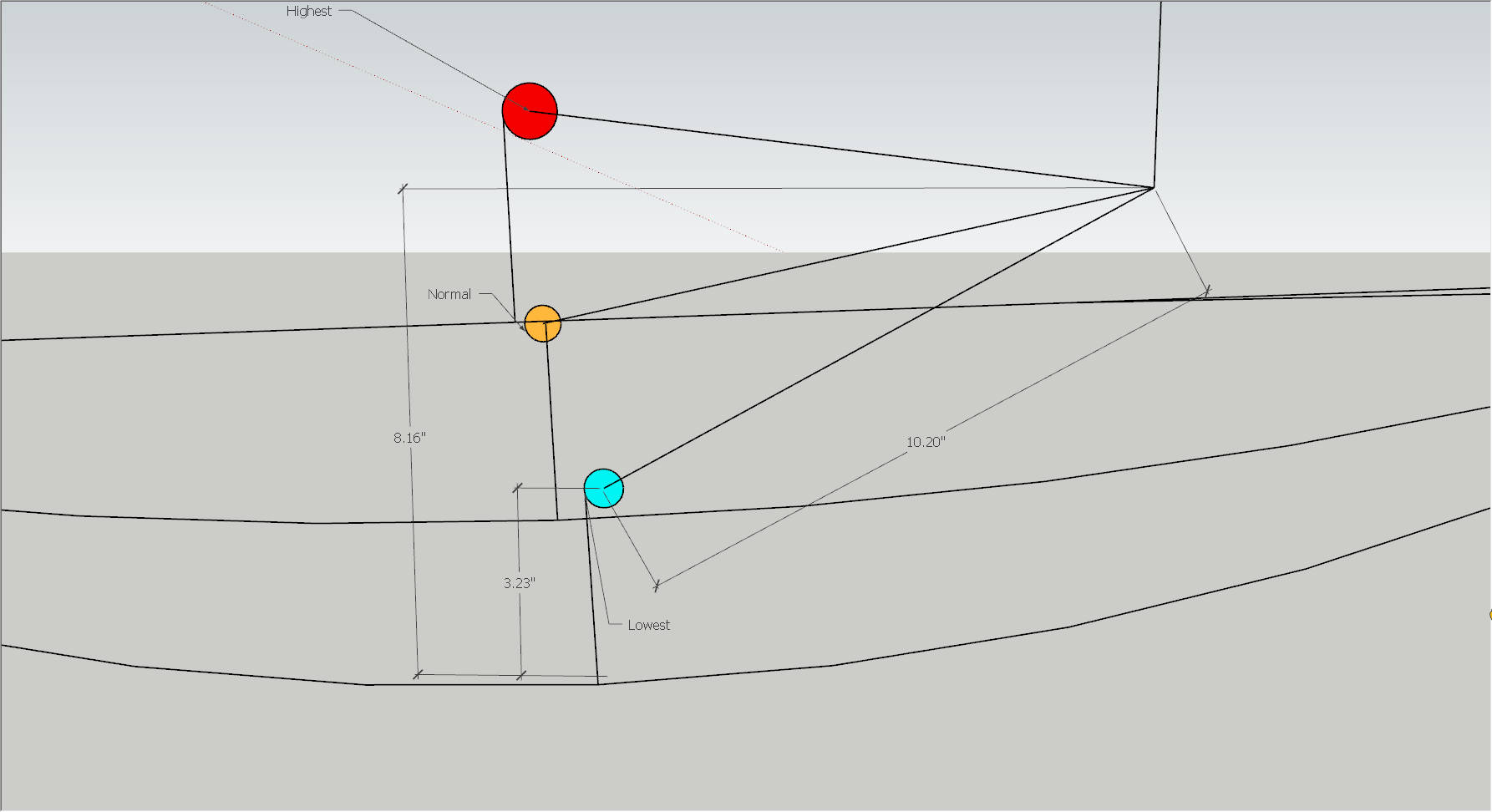

In some better news, I managed to score a Sweet Mfg. hydro assist servo which mounts along the steering column. I will be keeping the nice, big, stock steering box, and adding an assist cylinder between the pumpkin and the tierod. My thinking is this should decrease force on the pitman arm, steering arm, and draglink, since hydraulic power is applied there rather than at the steering box itself.

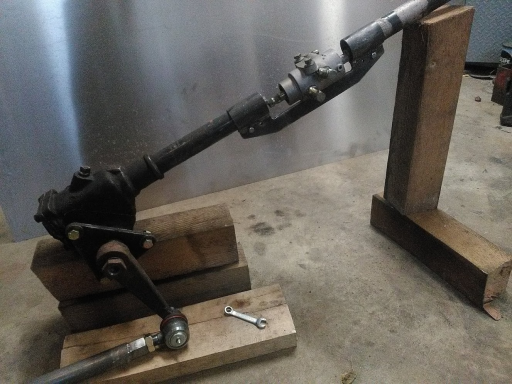

Thank you - it's a fun build for sure! So with the D60, since it doesn't have a crush sleeve, can I simply re-torque the pinion nut, confirm the gears mesh properly with marking compound, and it should be fine? The last owner put a new yoke on it but never torqued it down properly - no issue with "reusing" the old shims like there would be with "reusing" a crush washer, correct?Dana 60s don't have crush sleeves. They use shims to set pinion depth and bearing preload. Have you tried looking for a Dana 70 dually rearend from a Chevy dually? That's what would have been the rearend most likely that came behind your front axle your using. Be aware they came in different widths depending on if it's a cab and chassis or pickup bed.

Cool build, looking forward to it.

If anyone has a steering arm for a Dana 60, I'd be interested in taking it off your hands, by the way. At some point in this axle's life, someone welded the nuts and studs together, and to the steering arm. I don't know what they were thinking, but it was hot enough to gouge halfway through the studs. The steering arm was even tacked to the knuckle and it was a pain in the ass to remove. Needless to say, I need a new one...

In some better news, I managed to score a Sweet Mfg. hydro assist servo which mounts along the steering column. I will be keeping the nice, big, stock steering box, and adding an assist cylinder between the pumpkin and the tierod. My thinking is this should decrease force on the pitman arm, steering arm, and draglink, since hydraulic power is applied there rather than at the steering box itself.