Pioneer I

Here is what I ended up with. The baseline ended up being 29.25" center to center, and 6" from the front of the bumper to the center of the first hole. Then the rest of it I was able to line up using the measurements CJ provided me.

I test fit it all again to make sure everything lined up the way I wanted it to and that I had in fact measured right. I did one side first and verified it was all good and then simply replicated the measurements to the other side. I had to redo the first attempt after changing the battery in my digital calipers because a couple of the measurements were off just enough to cause the three bolt holes to not align with each other correctly.

Once that was all done then it was time to drill the holes. I did this in four steps, first using a 1/8" bit to get the hole started in the right place, then stepped up using slightly larger bits until I got to the final 1/2" bit to finish off the holes. Never start with a bit that large unless you don't care at all about alignment, because you're holes WILL wander and quite a bit at that. Fortunately I was close enough that I only had to slightly coax the third bolt on each side in, but all that took was using my ratchet to thread it in.

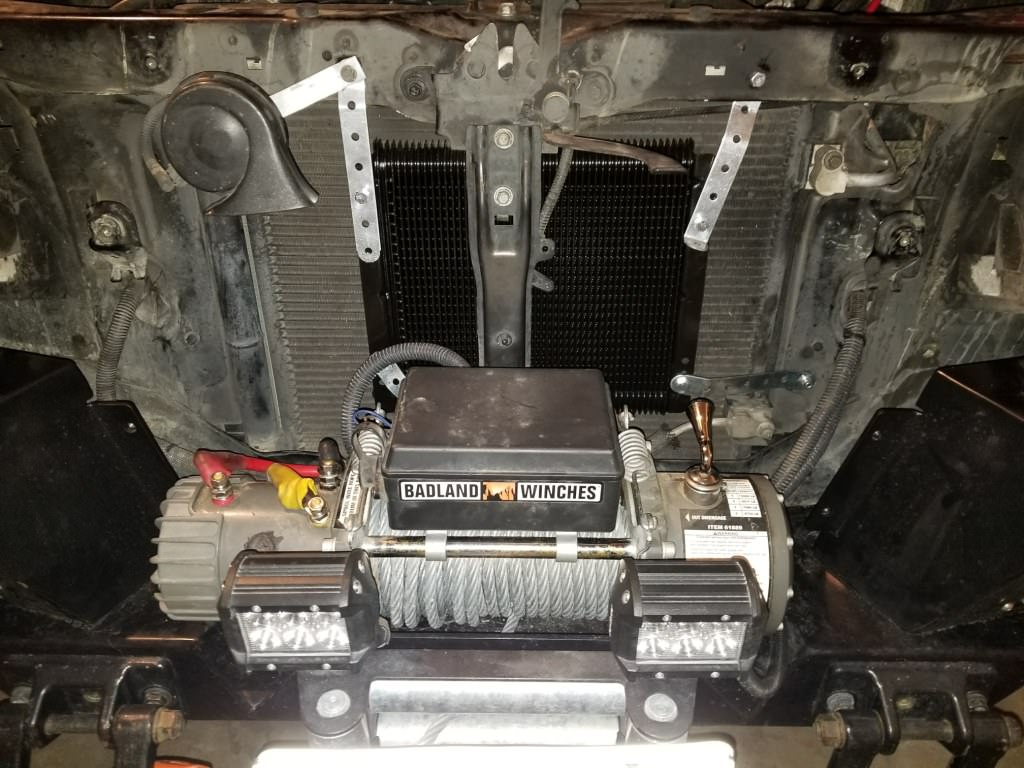

Here it is after drilling and removing the tape:

And then all bolted up:

I test fit it all again to make sure everything lined up the way I wanted it to and that I had in fact measured right. I did one side first and verified it was all good and then simply replicated the measurements to the other side. I had to redo the first attempt after changing the battery in my digital calipers because a couple of the measurements were off just enough to cause the three bolt holes to not align with each other correctly.

Once that was all done then it was time to drill the holes. I did this in four steps, first using a 1/8" bit to get the hole started in the right place, then stepped up using slightly larger bits until I got to the final 1/2" bit to finish off the holes. Never start with a bit that large unless you don't care at all about alignment, because you're holes WILL wander and quite a bit at that. Fortunately I was close enough that I only had to slightly coax the third bolt on each side in, but all that took was using my ratchet to thread it in.

Here it is after drilling and removing the tape:

And then all bolted up: