Ok so how would I build this...

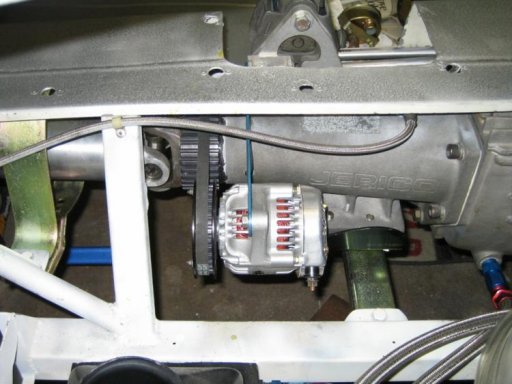

1. graft a crank pulley onto the pinion end.

2. make brackets to hold alternator.

3. use overdrive pulley on alternator (smaller)

4. on my 7 wire trailer plug, use the lead commonly used for the back up lamp to turn it on with the ignition. Or run a 78 amp, mid 80's GM alternator. They self energize real easy.

5. run an 8 gauge wire to the battery with a 100 amp manual reset breaker. That way you can disconnect power to it when your parked if you want/need to.

OR

1. install solar panel and controller.

Or

Wire your truck to charge it like the rest of the world.

When your calculating how much alternator you need. average vehicle at night, wipers on, draws 20-30 amps + any add on accessories. Add in 40 amps per battery in vehicle. Add in 40 amps per battery in trailer. Add in 10% over the total just because and there you go.

Personally i like the extra charging system at the trailer and a solar panel. One of my buddies at work drew up the plans to install motors at the trailer hubs to give it power. Great idea, stupid expensive. the downfall is, too hard to do regenerative breaking and the battery pack is too difficult to charge. OH and its real heavy.