Off-Road Ranger I

That's no kidding & thanks!Probably the best feeling on a swap project is running with good oil pressure! Congrats.

I was getting all sorts of sketched out when I first turned it over & it wasn't budging the needle on the electronic oil pressure gauge, so I plumbed in a spare mechanical gauge I had to go alongside it, just to verify. Then we realized the batteries haven't been on any kind of charger since I bought them a while back & were not ready to turn over that much compression. Oops. Even after a top up on the angry pixies the thing still didn't want to cough up any smoke! We thought maybe we weren't getting enough air out of the injection lines, or maybe the oil priming process with the drill-pump somehow didn't get enough thru the engine to prime the oil pump's rotors.

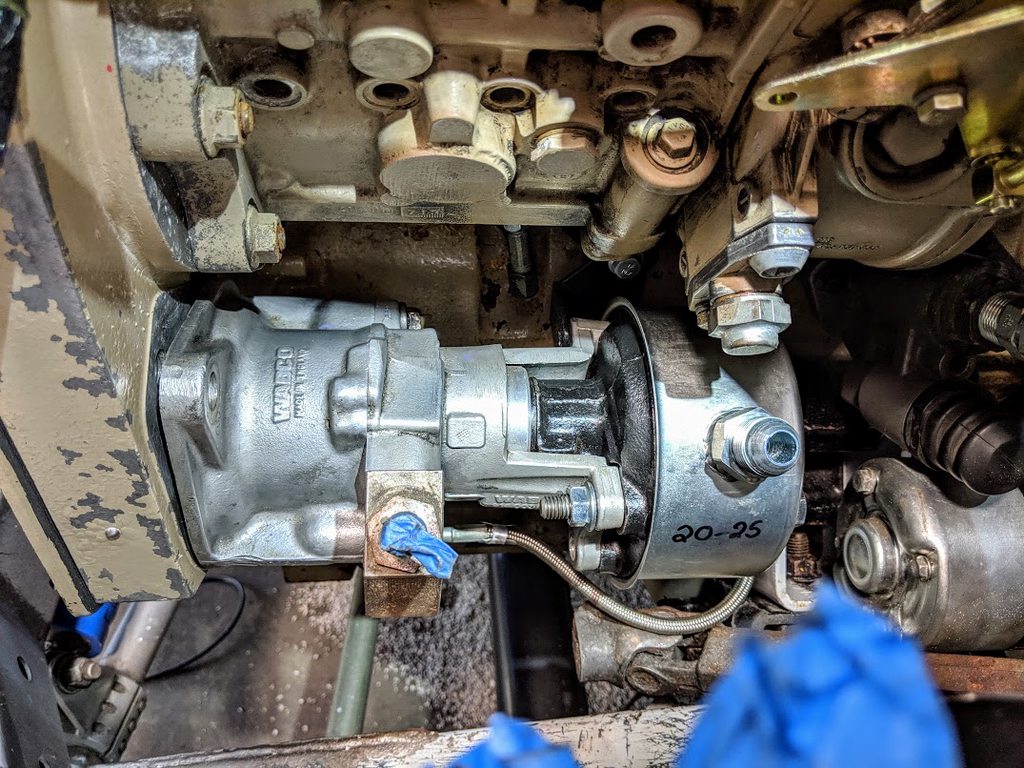

But it was none of the above & ended up being me just chasing my tail & overthinking things. Looking back at it, the thing I missed was stupid simple. The lever I pulled out of the leftover parts box (that was from the original mud-pump this engine was in) and installed temporarily for the start-up was letting the throttle shaft on the injection-pump spring back from the idle range into full shutdown... didn't even realize until I reached down & gave it a wiggle while the starter was cranking & BOOM it started running!

It was running a little rough at first, although not for long after I bled off the trapped air in those new fuel lines by cracking the nuts on the injectors. Runs great & doesn't shake anywhere near what I was expecting or had seen in other 4BT videos! It's not straight-6 smooth with a glass of water on top without a ripple, more of a T-rex stomping around kind of water in that glass. Even so I'm genuinely surprised how stable it is, & the shutdown shake isn't bad at all either.

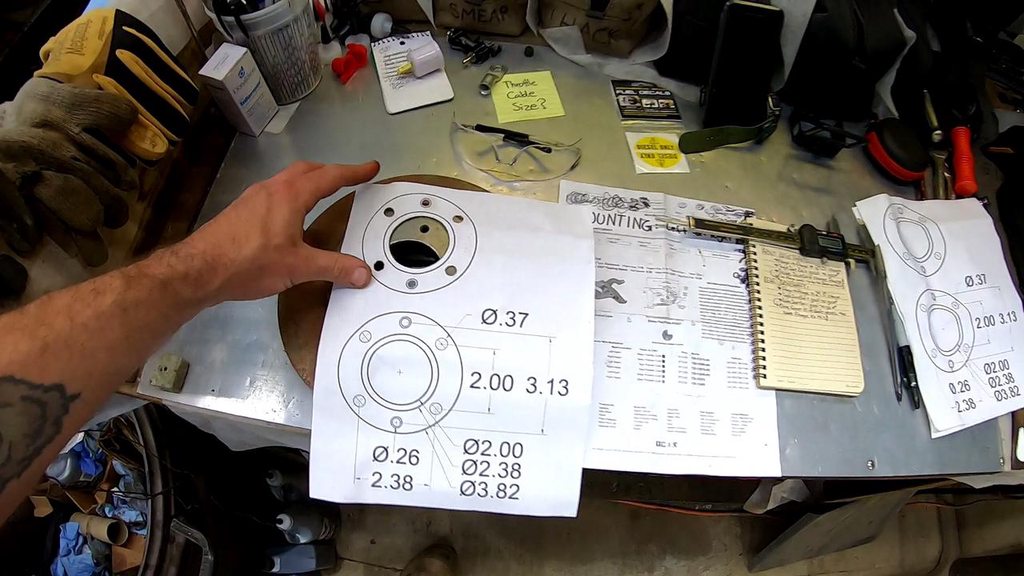

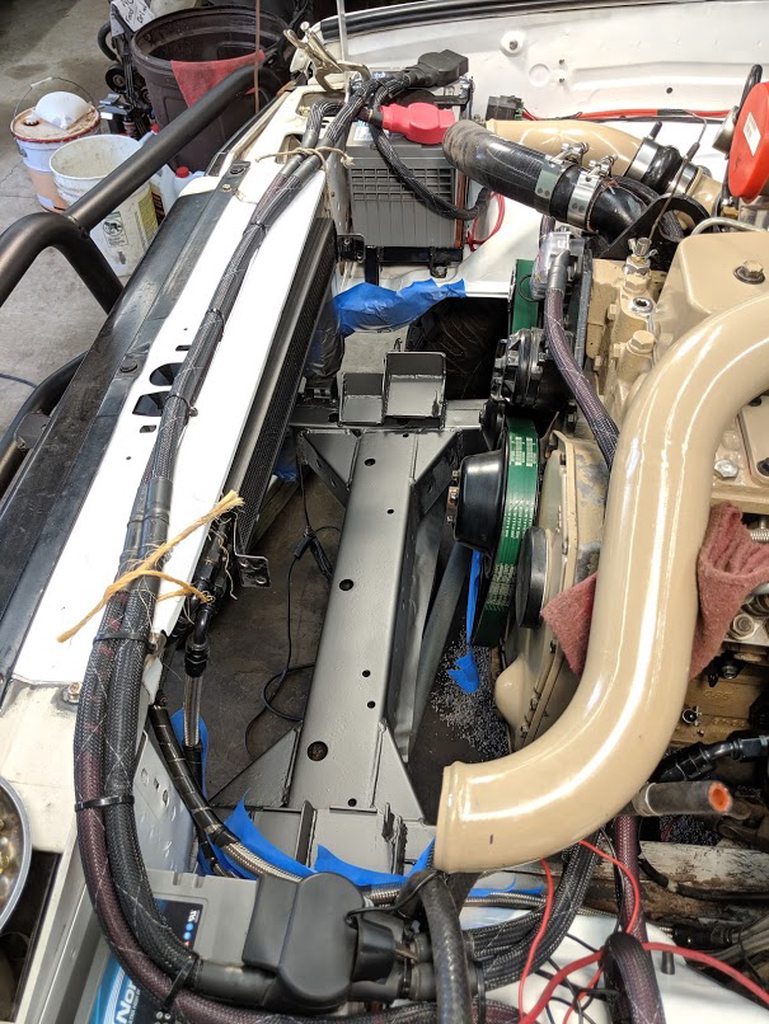

The thing starts so fast! I swear the crankshaft can barely get half a rotation before it's started. And here I was thinking I may have been excessively rough on the starter during all that cranking & hurt it. Now to get rocking on all the connections it needs (driveshaft mods, clutch pedal, throttle cable, steering gear mods, etc) to get on the road & out of the shop!

The windshield was splattered in even more diesel than I was after that night: