.

Hey David, thanks.

I've found that truck bed lining, depending on amount of grit (some brands allow adding more or less) can be rough on the bottoms of cases and containers, as well as be a bit coarse for bare feet if using the space for adventuring. I have it in my trailer bed and often wish I didn't. I put down a large piece of cardboard or strips of 1/4" ply in the trailer to go under some items so they're not scoured continuously by the grit when sliding gear in and out all the time.

As for ply thickness, I've found 3/4" isn't necessary unless needed to span across a wide opening. Though for a floor, because it is laying fully supported by the truck bed, you can use 1/2" or even 3/8". Mine is actually 12mm, or 0.476".

Also, if installing e-track or other track in your floor, and recess it like mine, keeping the thickness of the ply to the same height of the track will help the ply last

much longer, and let is slide anywhere a lot easier. Otherwise, gear will catch and stick at edges of the ply, and it will splinter and fray prematurely along the lengths of the track.

View attachment 200733

Indoor outdoor mat pulled back to show 12mm (0.476") thickness of ply and e-track. Being as close in height as possible prevents a lot of problems. This is the leading edge at the rear doors; not too shabby for having been installed and subject to weather and shoving things in and out for over eight years.

Though for years I had e-track going sideways at the rear doors and again at the other end of the 8' long pieces, to provide more strap anchoring points. I have since removed the cross pieces. The track at the rear doors also helped protect the edge of the ply from pallet and fork lifts.

View attachment 200736

E-track crossways at the rear doors

Also, if using 3/4" ply, the deeper recessed track will be uncomfortable under foot and make for an uneven surface if you lay an indoor-outdoor mat over it for use as living quarters:

View attachment 200735

Summer 2019 after an 8 month adventure. Both sides and floor, coated with Satin Polycrylic, have held up extremely well. A good rugged indoor/outdoor mat has proven to be a perfect solution for my style of adventuring. It provides an easy to clean, easy to remove, and very comfortable surface.

I always bought my cargo control gear from

Lodi Metals in Bellville OH and would stop in when going through that part of the country. They have a wide selection of

e-track rails in various lengths, both horizontal and vertical, airline style

L track, and have a ton of

ratchet strap options. Great folks.

US Cargo Control, now in Urbana IA, has a wide array of cargo gear, too. You see their name all over straps etc.

I used to have regular exterior ply as a floor in the van, and over time saw it was okay for use as a work truck, but not for adventuring, as it's just too rough and splintery. Since going to the much smoother and higher-quality 12mm birch, with two or three coats of

Satin Polycrylic (sanded and tack clothed in between coats), I couldn't be more pleased. I thought I'd have to sand and give it another coat every year or two, but have never had to.

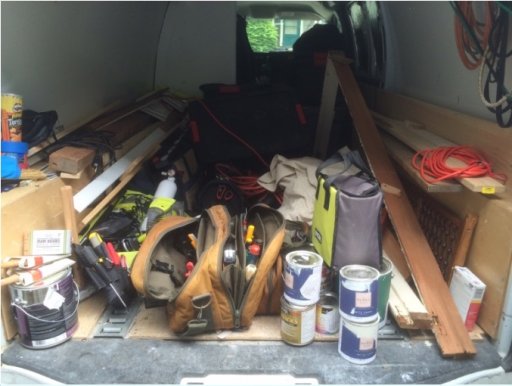

View attachment 200734

2012, with ext ply, before I switched to 12mm birch ply.

If the price of birch ply stay somewhat reasonable, though, I'm redoing the entire interior of the van, with lower side cabinets a bit taller; some counter cabinets for sink and more storage; and better places to contain my cases, containers, tripods and fishing poles. All removable back down to just the lower side cabinets so I can still haul pallets or loads of full-sized sheet goods and other lumber when helping folks with off-grid solutions. I have 12' of floor from rear doors to back of the seats.

Hope you find a solution that works just right.

.