Enthusiast III

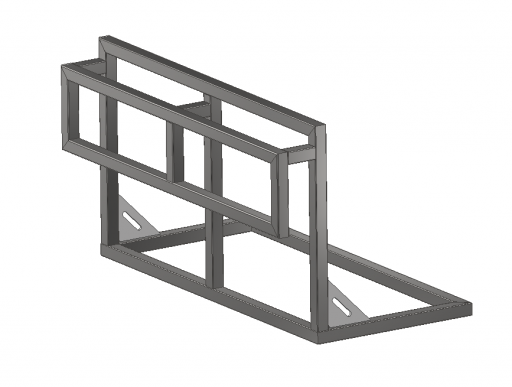

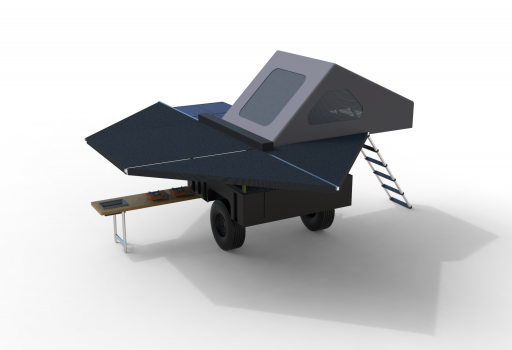

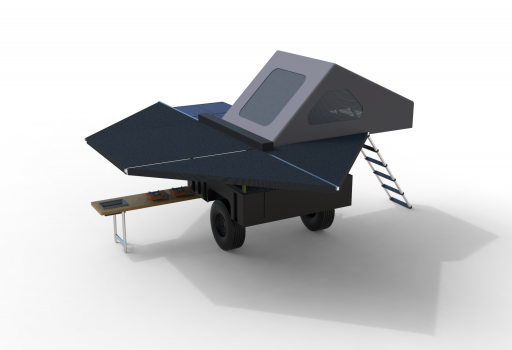

Living in Arizona one of my hobbies is getting out into the wild to take photos, primarily astrophotography (Can't share those photos on the forums as the files are too big). There are plenty of locations I've only ever traveled to in the dark, the first several times I went to the Grand Canyon I couldn't tell you what it looked like during the day. The overnight trips were spent sleeping either in a ground tent or the back of the Jeep during the colder months. Since I now have access to a CNC plasma cutter I decided it was time to bite the bullet and build an overlanding trailer. I landed on the M1101/M1102 as the most viable platform for my needs. Picking up my trailer tomorrow and excited to get started, I don't have the slightest idea of when my Smittybilt Gen2 RTT will arrive so I'm trying to have the rack finished within the next 2 weeks.

I figured I would start with the basics that I know I'll need and fill in the remainder after camping in the trailer a few times. Planning to add some custom storage boxes on both sides of the rack, I'm going to design those next once I finish my gear list for each box.

I was originally going to use a chunk of butcher block I have laying in the Garage but considering the weight I think I'm going to plasma cut and form an aluminum (or possibly stainless) kitchen extension out of sheet metal instead.

I was thinking of adding a hydraulic solenoid valve to the surge brake that would be triggered when the tow vehicle is put in reverse. Working on designs for mounting the following next:

1. 25 Gallon Grey water tank and pump (Fits in front of the wheel well, Right side)

2. 2 x Deep cycle batteries (Fits behind wheel well, left side)

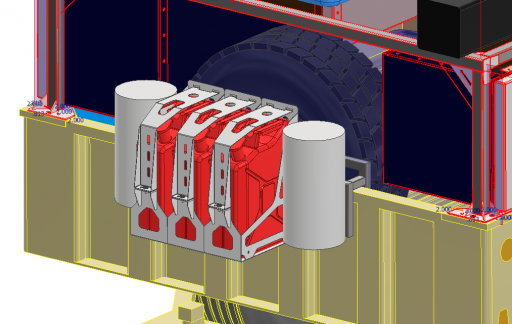

3. 2 x Propane Tank mounts

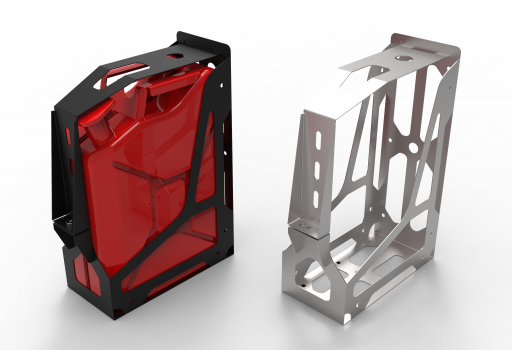

4. 2 x 5 Gallon Gas cans

5. Foldable side steps

Still looking for a good 270 Degree awning option. I like the Overland Vehicle Systems Nomadic 270, any other suggestions on awnings?

I figured I would start with the basics that I know I'll need and fill in the remainder after camping in the trailer a few times. Planning to add some custom storage boxes on both sides of the rack, I'm going to design those next once I finish my gear list for each box.

I was originally going to use a chunk of butcher block I have laying in the Garage but considering the weight I think I'm going to plasma cut and form an aluminum (or possibly stainless) kitchen extension out of sheet metal instead.

I was thinking of adding a hydraulic solenoid valve to the surge brake that would be triggered when the tow vehicle is put in reverse. Working on designs for mounting the following next:

1. 25 Gallon Grey water tank and pump (Fits in front of the wheel well, Right side)

2. 2 x Deep cycle batteries (Fits behind wheel well, left side)

3. 2 x Propane Tank mounts

4. 2 x 5 Gallon Gas cans

5. Foldable side steps

Still looking for a good 270 Degree awning option. I like the Overland Vehicle Systems Nomadic 270, any other suggestions on awnings?

Last edited: