Advocate III

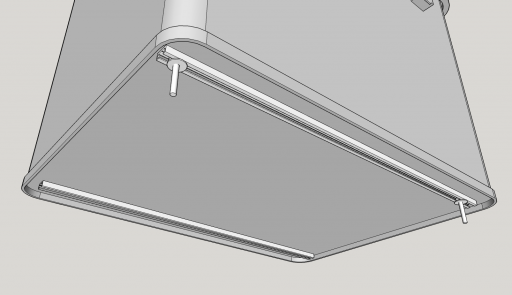

Hey all, I scored a great aluminum Zarges case on clearance that I'd like to turn into a portable desk/work surface/table for camp and van. It is a perfect size at approx 19 x 35 x 7.5 deep. It has a 1/2" recess all the way around on the underside.

I would like to be able to mount legs simply at each corner. I'd rather not have an accordion style expanding leg setup that the desk just sits on, but four simple straight legs I can attach and remove easily that will stay in place if I move the desk around. The case is long enough to hold the legs inside when not being used.

One possibility is threaded screw mounts in each corner installed on the underside that would receive threaded rod inserted in the top of each leg. The mounts can be no more than 1/2" in height, so I can still slide the case without the mounts catching when the legs are not installed. The mounts could be secured from the inside of the case.

I poked around online but haven't found just what I want. A lot of small threaded tee inserts that don't seem substantial enough. I'd like the thread to be fairly good sized, not just 1/4".

Anyone know of a threaded female mount that might work?

Another option I'm considering would be to create a square or rectangular hole in each corner, with a sleeve on the inside to receive metal or wooden legs. Just slip 'em in, maybe with a set screw or pin on the inside so they don't slip if I move the desk. This might actually be easier to set up than finding and securing the right threaded mounts and threaded inserts for the leg ends. It would also allow the legs to have a slight splay for greater stability.

Either way of mounting would allow having both a regular length and a short length set of legs.

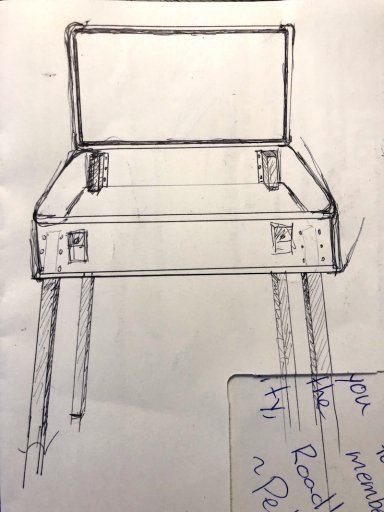

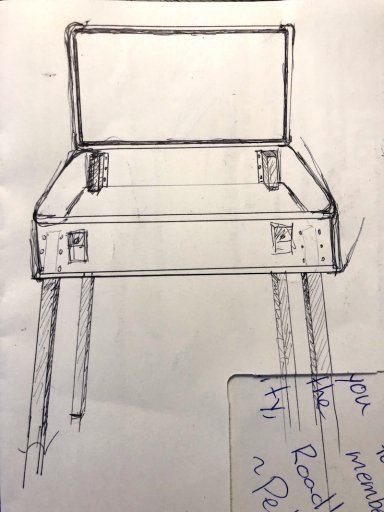

Envelope sketch of leg sleeve idea:

Actually, looking at it now, it might be easier and just as stable to create the leg holder sleeves on the outside and at each end of the case, instead of cutting holes and having them slide up through the bottom into interior sleeves. I'd bend the sleeves up out of aluminum at the slight angle I want, with top and side flanges to rivet through the case. Then have a lock pin for each leg to hold them in place.

Any other ideas, solutions, materials I should consider?

.

I would like to be able to mount legs simply at each corner. I'd rather not have an accordion style expanding leg setup that the desk just sits on, but four simple straight legs I can attach and remove easily that will stay in place if I move the desk around. The case is long enough to hold the legs inside when not being used.

One possibility is threaded screw mounts in each corner installed on the underside that would receive threaded rod inserted in the top of each leg. The mounts can be no more than 1/2" in height, so I can still slide the case without the mounts catching when the legs are not installed. The mounts could be secured from the inside of the case.

I poked around online but haven't found just what I want. A lot of small threaded tee inserts that don't seem substantial enough. I'd like the thread to be fairly good sized, not just 1/4".

Anyone know of a threaded female mount that might work?

Another option I'm considering would be to create a square or rectangular hole in each corner, with a sleeve on the inside to receive metal or wooden legs. Just slip 'em in, maybe with a set screw or pin on the inside so they don't slip if I move the desk. This might actually be easier to set up than finding and securing the right threaded mounts and threaded inserts for the leg ends. It would also allow the legs to have a slight splay for greater stability.

Either way of mounting would allow having both a regular length and a short length set of legs.

Envelope sketch of leg sleeve idea:

Actually, looking at it now, it might be easier and just as stable to create the leg holder sleeves on the outside and at each end of the case, instead of cutting holes and having them slide up through the bottom into interior sleeves. I'd bend the sleeves up out of aluminum at the slight angle I want, with top and side flanges to rivet through the case. Then have a lock pin for each leg to hold them in place.

Any other ideas, solutions, materials I should consider?

.