Enthusiast III

Been tossing this idea around in my head...

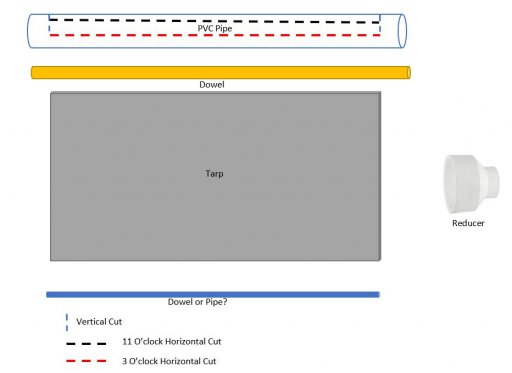

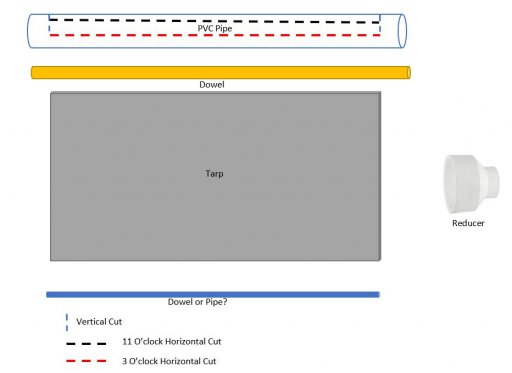

I have sketched out a DIY shower, pressurized 4" PVC was thinking of having a "matching" awning set up

Passenger side has the 4" (painted black) PVC for the shower

Driver Side has another 4" black PVC, this would house the awning

My plan thus far....

TBD Length of 4" PVC = Housing

At the same length of the Housing a 1.5" Dowel

Take that dowel and shave the ends down reducing lightly less then 1.5

I'd take the large PVC and cut it lengthwise, not in half but maybe 10 0'Clock to 3 O'clock and a several inches in (allowing for end caps)?

piano hinges at 11 O'clock

Latches at 3 O'Clock

prior to installing hinges I would insert in one end one of the reducer sets, set in my dowel then cap off with the 2nd reducer (this is why ends are trimmed on dowel)

affix the awning to the dowel

Thinking some sort of crank at one end to reel the awning in??? Maybe something I use a drill for

Other end of awning affixed to another dowel or something rigid...still debating this end

My thought process is this, PVC relatively cheap, I have a nice camping tarp

The reason for the reducers is to keep the "reel" in the middle, the smallest dia will be 1.5, using a 1.5 wood dowel, shaving the ends down keep the middle lined up with the reducers keeping it snug in the middle

This may be all over the place but see where I'm going??

Thoughts????

I have sketched out a DIY shower, pressurized 4" PVC was thinking of having a "matching" awning set up

Passenger side has the 4" (painted black) PVC for the shower

Driver Side has another 4" black PVC, this would house the awning

My plan thus far....

TBD Length of 4" PVC = Housing

At the same length of the Housing a 1.5" Dowel

Take that dowel and shave the ends down reducing lightly less then 1.5

I'd take the large PVC and cut it lengthwise, not in half but maybe 10 0'Clock to 3 O'clock and a several inches in (allowing for end caps)?

piano hinges at 11 O'clock

Latches at 3 O'Clock

prior to installing hinges I would insert in one end one of the reducer sets, set in my dowel then cap off with the 2nd reducer (this is why ends are trimmed on dowel)

affix the awning to the dowel

Thinking some sort of crank at one end to reel the awning in??? Maybe something I use a drill for

Other end of awning affixed to another dowel or something rigid...still debating this end

My thought process is this, PVC relatively cheap, I have a nice camping tarp

The reason for the reducers is to keep the "reel" in the middle, the smallest dia will be 1.5, using a 1.5 wood dowel, shaving the ends down keep the middle lined up with the reducers keeping it snug in the middle

This may be all over the place but see where I'm going??

Thoughts????